Method and device for conducting absolute measurement on electrical conductivity of solution and high-temperature melt

A high-temperature melt, absolute measurement technology, applied in the direction of fluid resistance measurement, etc., can solve the problems of the direct measurement of the geometric size of the conductivity cell, the expansion and deformation of the conductivity cell, etc., and the device and method are simple and easy to implement, and the polarization effect and edge effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

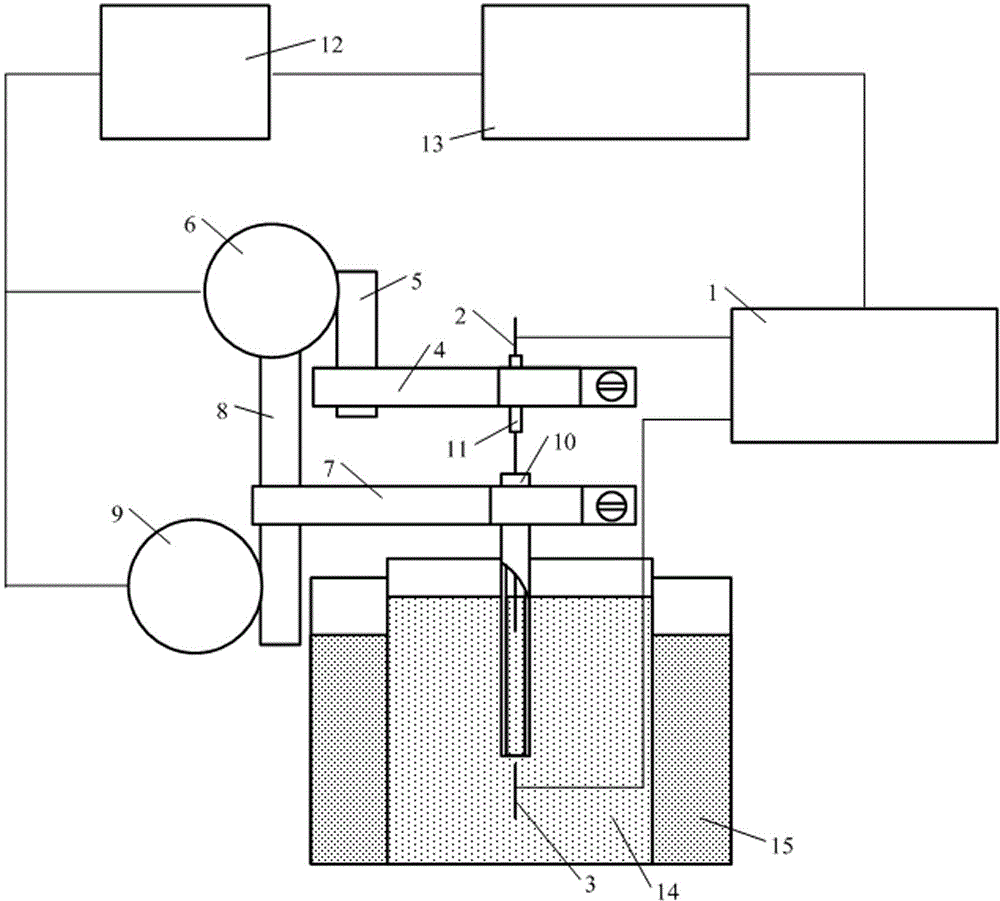

[0049] The structure of the absolute measurement device for the conductivity of solutions and high-temperature melts is as follows: figure 1 As shown, it is a single capillary conductivity cell device, including a first electrode 2, a second electrode 3, a first capillary 10, a capillary clamping device, an LCR tester 1, an electrode fixture 4 and a servo system 6, and the first capillary 10 is fixed on On the capillary clamping device, the first capillary 10 is perpendicular to the horizontal plane, the first electrode 2 and the second electrode 3 are connected to the connecting terminal of the measurement port of the LCR tester 1 through wires, the first electrode 1 is fixed on the electrode holder 4, and the electrode The fixture 4 is fixed on the electrode fixture bracket 5, and the electrode fixture bracket 5 is assembled with the servo system 6, and the servo system 6 is fixed on the capillary tube clamping device, wherein the first electrode 2 is inserted into the first ...

Embodiment 2

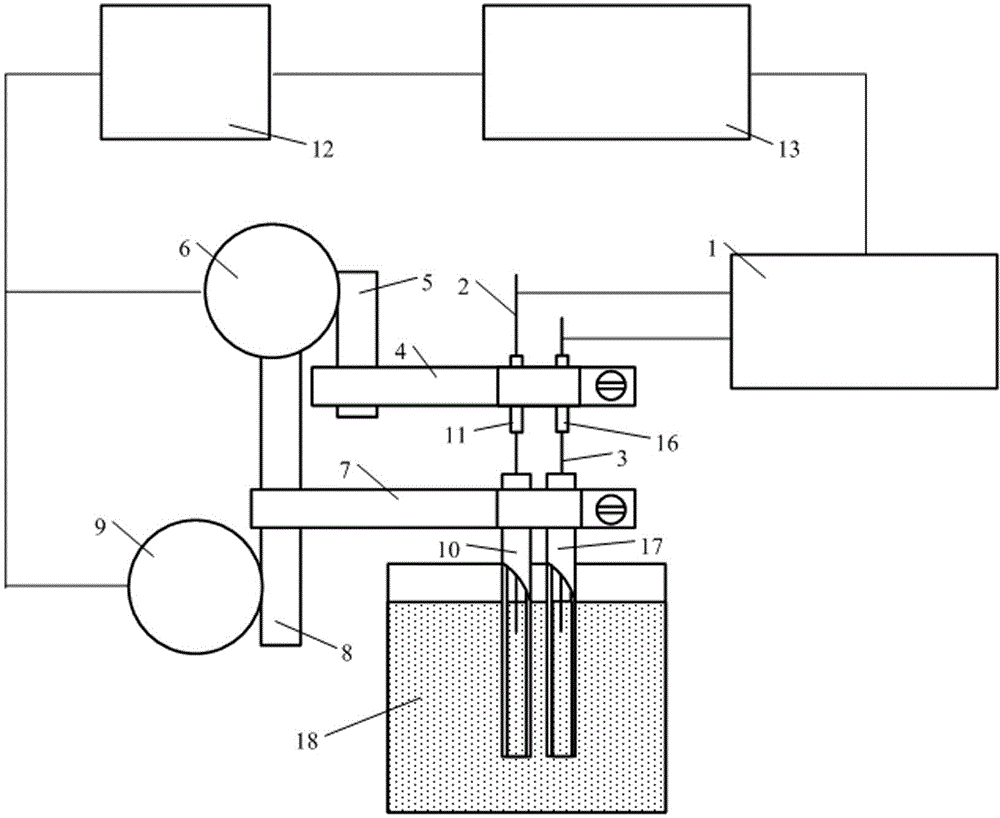

[0070] The structure of the absolute measurement device for the conductivity of solutions and high-temperature melts is as follows: figure 2 As shown, the structure is a double capillary conductivity cell device, including a first electrode 2, a second electrode 3, a first capillary 10, a second capillary 17, a capillary clamping device, an LCR tester 1, an electrode fixture 4 and a servo system 6 , the first capillary 10 and the second capillary 17 are fixed side by side on the capillary clamping device, the first capillary 10 and the second capillary 17 are perpendicular to the horizontal plane, the first electrode 2 and the second electrode 3 are measured by the wire and the LCR tester 1 The terminal connection of the port is connected, and the first electrode 2 and the second electrode 3 are fixed side by side on the electrode fixture 4, and the electrode fixture 4 is fixed on the electrode fixture bracket 5, and the electrode fixture bracket 5 is assembled with the servo ...

Embodiment 3

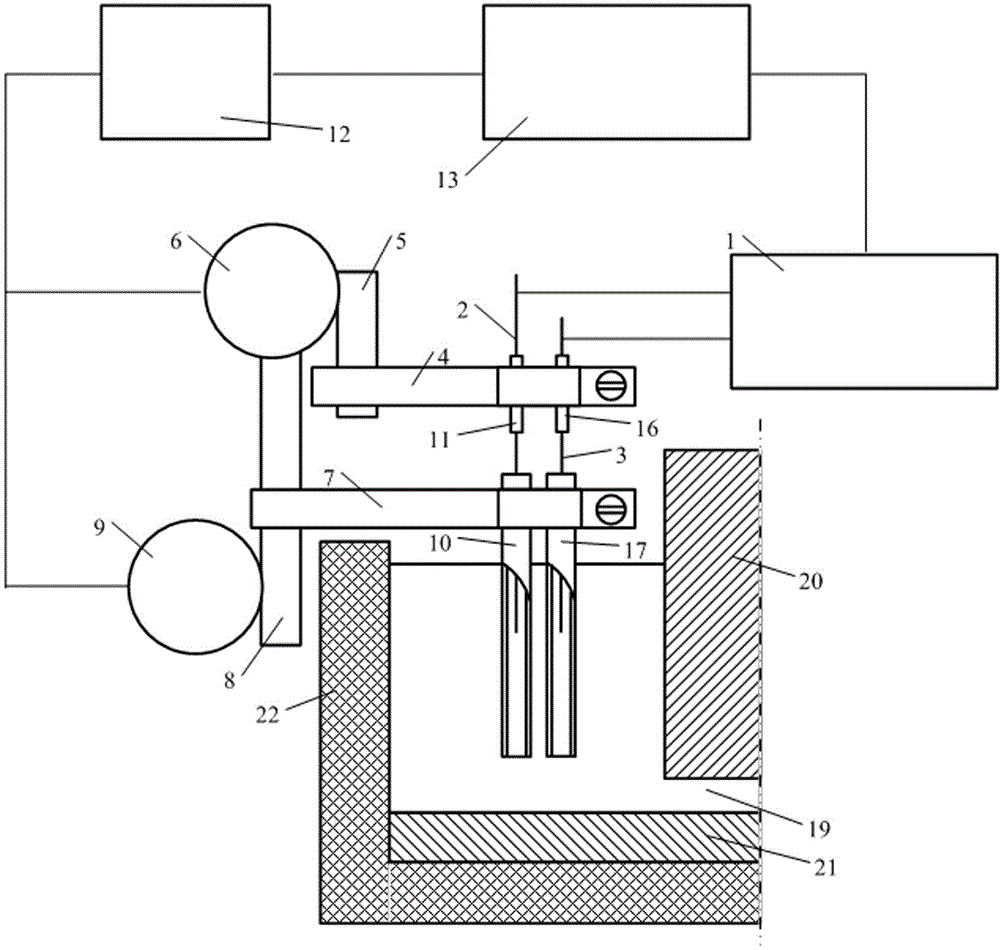

[0091] The structure of the absolute measurement device for the conductivity of solutions and high-temperature melts is as follows: figure 2 Shown, double capillary conductance cell device structure is the same as embodiment 2;

[0092] Use the above-mentioned device to measure the conductivity of the electrolyte melt in the aluminum electrolytic cell of a factory, measure the inner diameters of the first capillary and the second capillary in advance at 945°C, and immerse the double-tube conductivity cell of the above-mentioned device into the aluminum electrolytic cell. Be in the electrolyte melt of 945 ℃, other methods are with embodiment 2; Record the conductivity of electrolyte melt to be 2.24 ; Since there is no example of on-line measurement of the conductivity of the electrolyte melt in the aluminum electrolytic cell at present, the electrolyte sample in the electrolytic cell is taken out, and then measured under laboratory conditions, the measurement result is 2.21 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com