Electromagnetic pulse welding apparatus incorporating cooling insulators for welding metal sheets

A technology of pulse welding and electromagnetic pulse, which is applied in the direction of coil devices, welding equipment, metal processing equipment, etc., and can solve problems such as premature fracture of coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

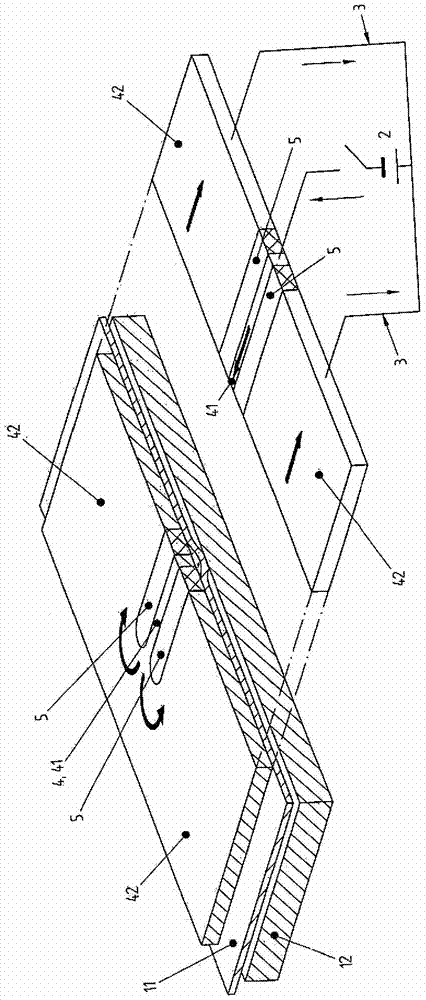

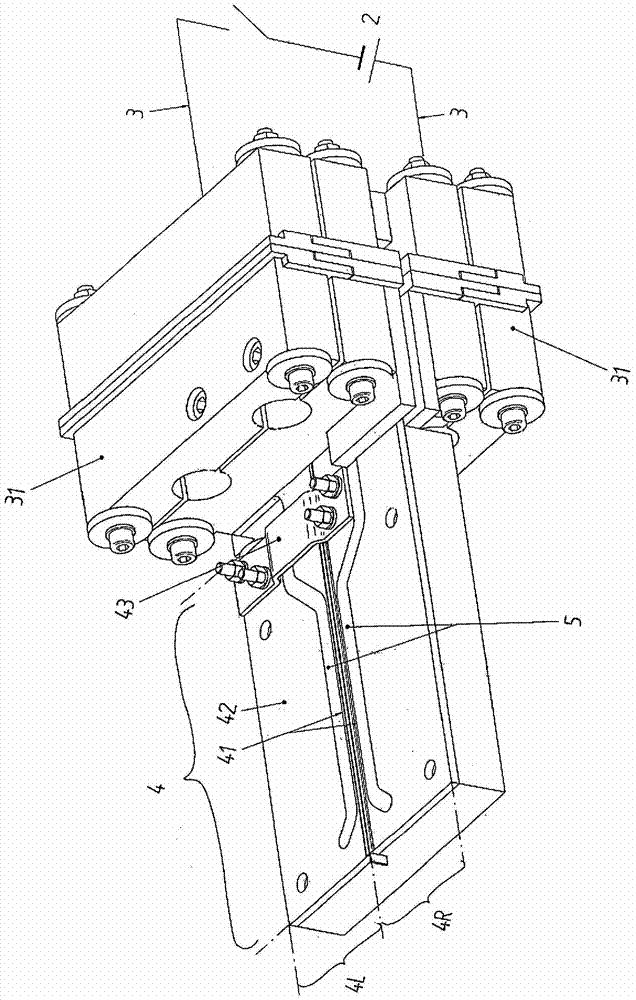

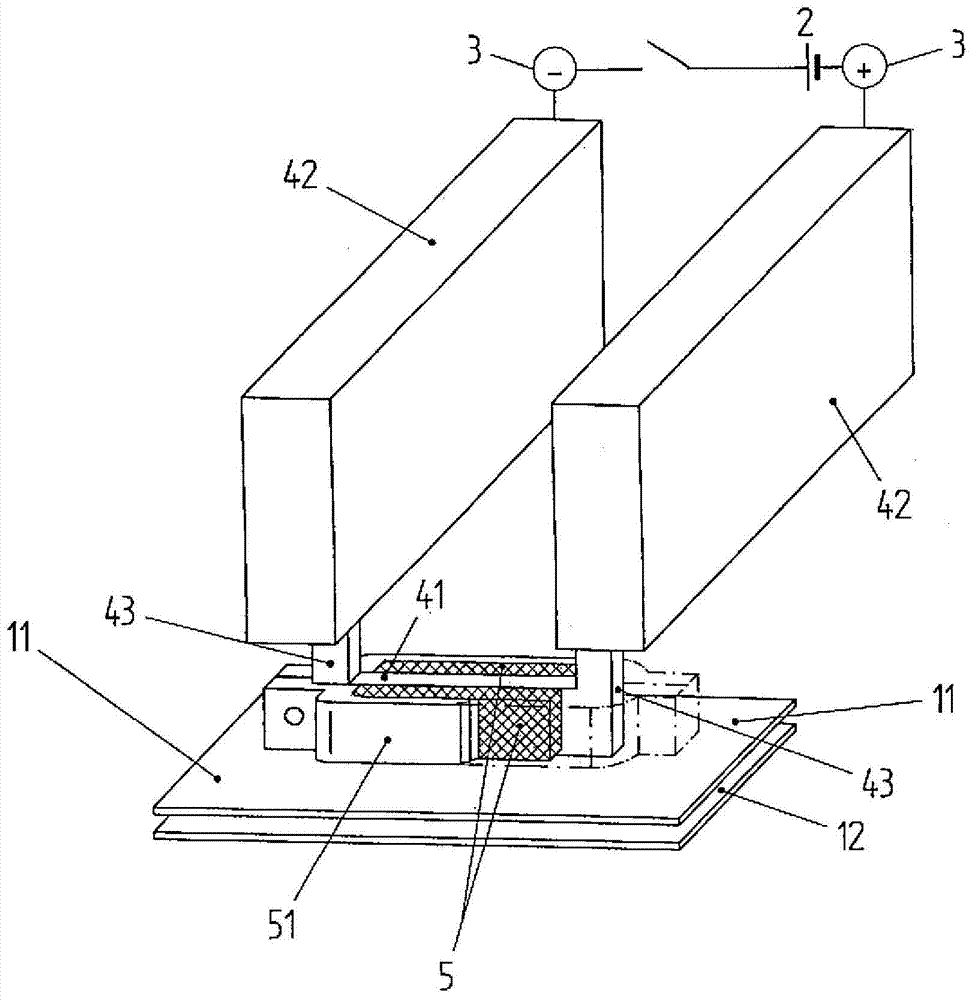

[0064] figure 1 An oblique view of a single-winding coil in the form of E is shown, cut transversely to the three legs of E. Said portion is continuous along a metal plate 11 which is arranged below and which is to be welded together with a metal part 12 located below it.

[0065] In the right-hand part of the coil 4, which is shown in section in the figure, it can be seen that the active part 41 is located in the centre. In each case it is adjacent to two opposite outer surfaces of the cooling insulator 5 , which are marked by means of cross-hatched end faces. The passive part 42 of the coil 4 is adjacent to the two other surfaces of each cooling insulator 5 .

[0066] exist figure 1 , the arrows show how the current flows from the power source 2 through the coil 4: when the switch is closed, the current flows into the active part 41 and then through the part of the coil 4 which is cut away in the figure and is therefore not visible , then enter the area shown at the top....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com