Method for selectively preparing thiophene compound by using biomass

A biomass and compound technology, applied in the direction of organic chemistry, can solve the problems of waste loss, resource waste, environmental pollution, etc., and achieve the effect of avoiding pre-treatment steps, reducing corrosion and pollution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

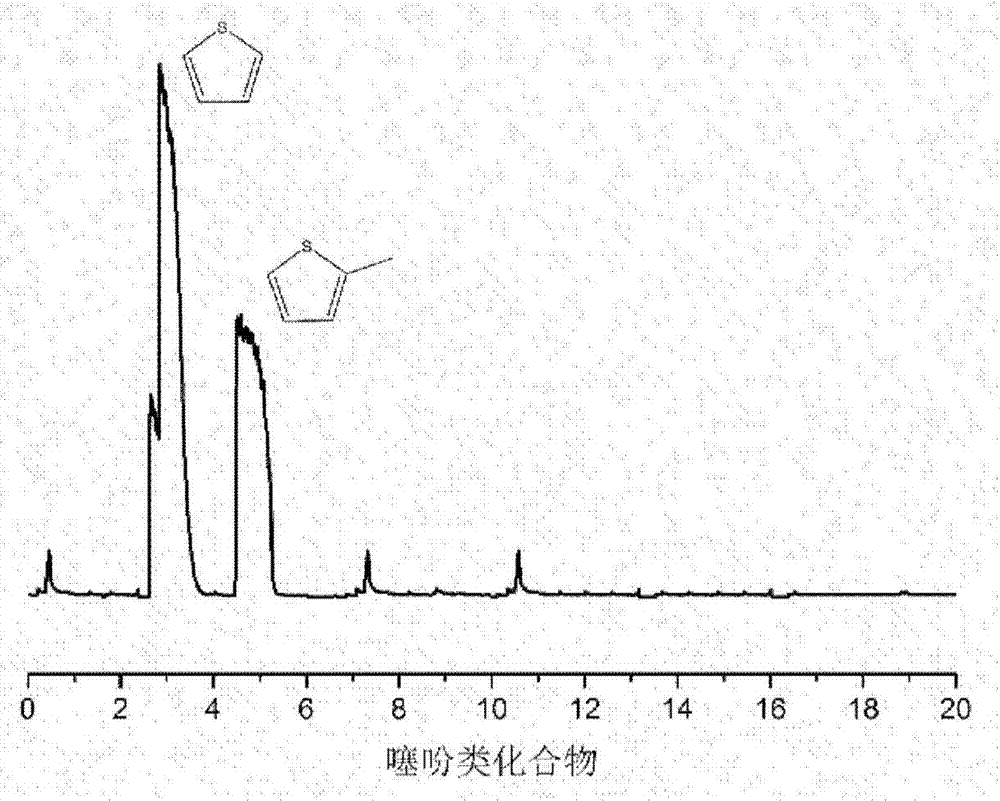

Image

Examples

Embodiment 1

[0047] In this example, a quartz tubular reactor with a diameter of 34 mm and a length of 300 mm was used. In the reactor, the catalyst was supported by quartz wool. Install the quartz reactor in a temperature-controlled furnace. During operation, hydrogen sulfide is used as a carrier gas, and its flow rate is controlled by a gas flow meter. The carrier gas used in this experiment was H 2 S or H 2 S / N 2 、H 2 S / He mixture. The powdery raw materials flow together with the carrier gas flow from the opening of the quartz tube to the pyrolysis interface. Liquid products flow from the reactor to the condenser and gaseous products are collected in gas sampling bags. Liquid and gaseous products were analyzed using a gas chromatograph.

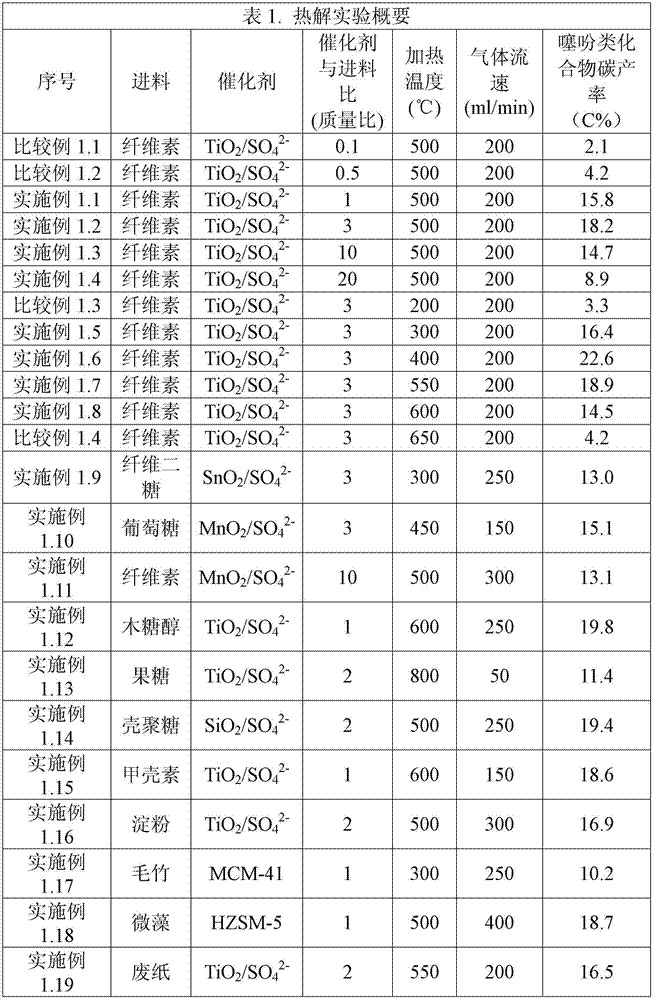

[0048] As representative of several embodiments, the catalytic pyrolysis tests described in Examples 1-4 were performed with powdered catalyst and feed (<140 mesh). Unless otherwise stated in this example, the reaction conditions were as descr...

Embodiment 2

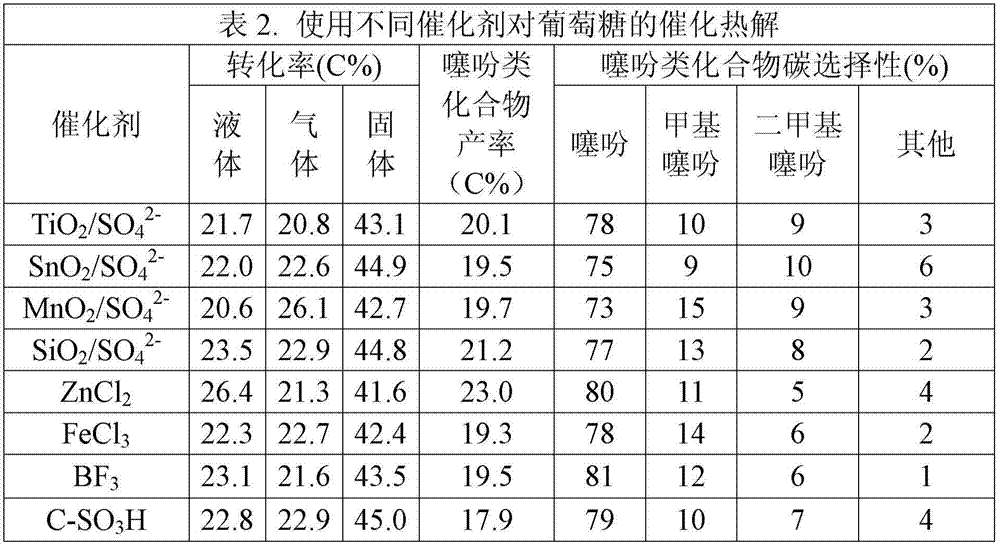

[0053] In this example, 6 different catalysts were tested for the catalytic pyrolysis of cellulose, including: TiO 2 / SO 4 2- , SnO 2 / SO 4 2- , MnO 2 / SO 4 2- , SiO 2 / SO 4 2- , ZnCl 2 , FeCl 3 , BF 3 ,C-SO 3 H. The powder reactant was prepared by physically mixing carbohydrate feed and catalyst. In this experiment, the ratio of catalyst to glucose was 2, the reaction temperature was 550°C, and the gas flow rate was 200ml / min. The catalyst was mixed with cellulose and ground into powder.

[0054]

Embodiment 3

[0056] In this example, the biomass was impregnated with liquid acids of different concentrations and volumes, and then filtered, dried and pulverized. Then, the treated biomass containing acid is subjected to a pyrolysis experiment at a certain temperature, and the liquid is collected to obtain bio-oil containing thiophene compounds. The bio-oil was collected and quantified by gas phase detection. Taking bagasse as an example in this embodiment, it is proved that the suitable acid concentration has a very important influence on the yield of thiophene compounds, and the suitable acid concentration is 0.01M-18M. It can be seen from Comparative Example 3.1 that when the acid concentration is too high or too low, the yield of thiophene compounds drops significantly.

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com