Bending handrail assembly of minitiller

A micro tillage machine and handrail technology, applied in the field of micro tillage machines, can solve the problems of high production cost, poor convenience and reliability of adjustment operation, complex structure, etc., and achieve low transformation cost, convenient and reliable operation, and large adjustment range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

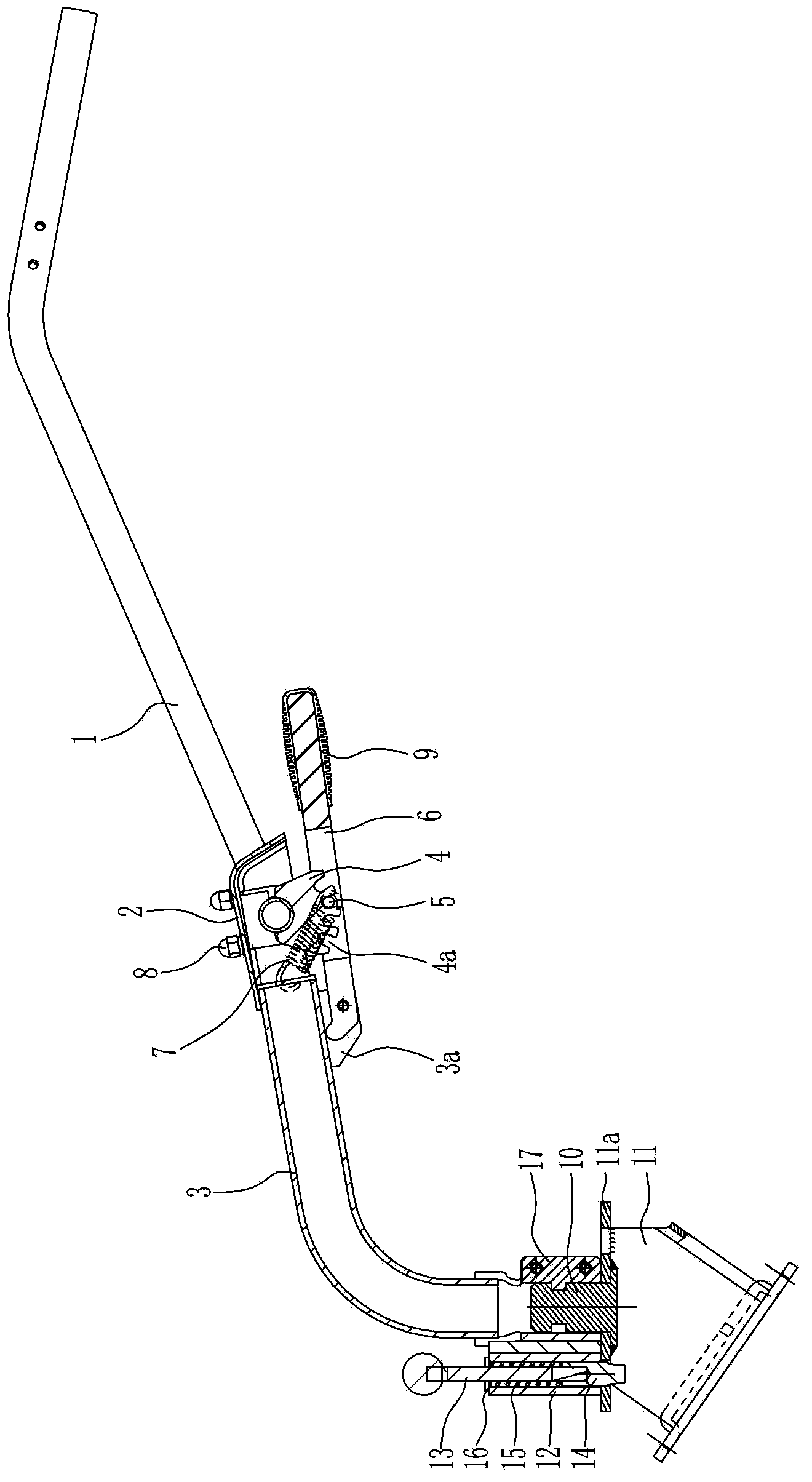

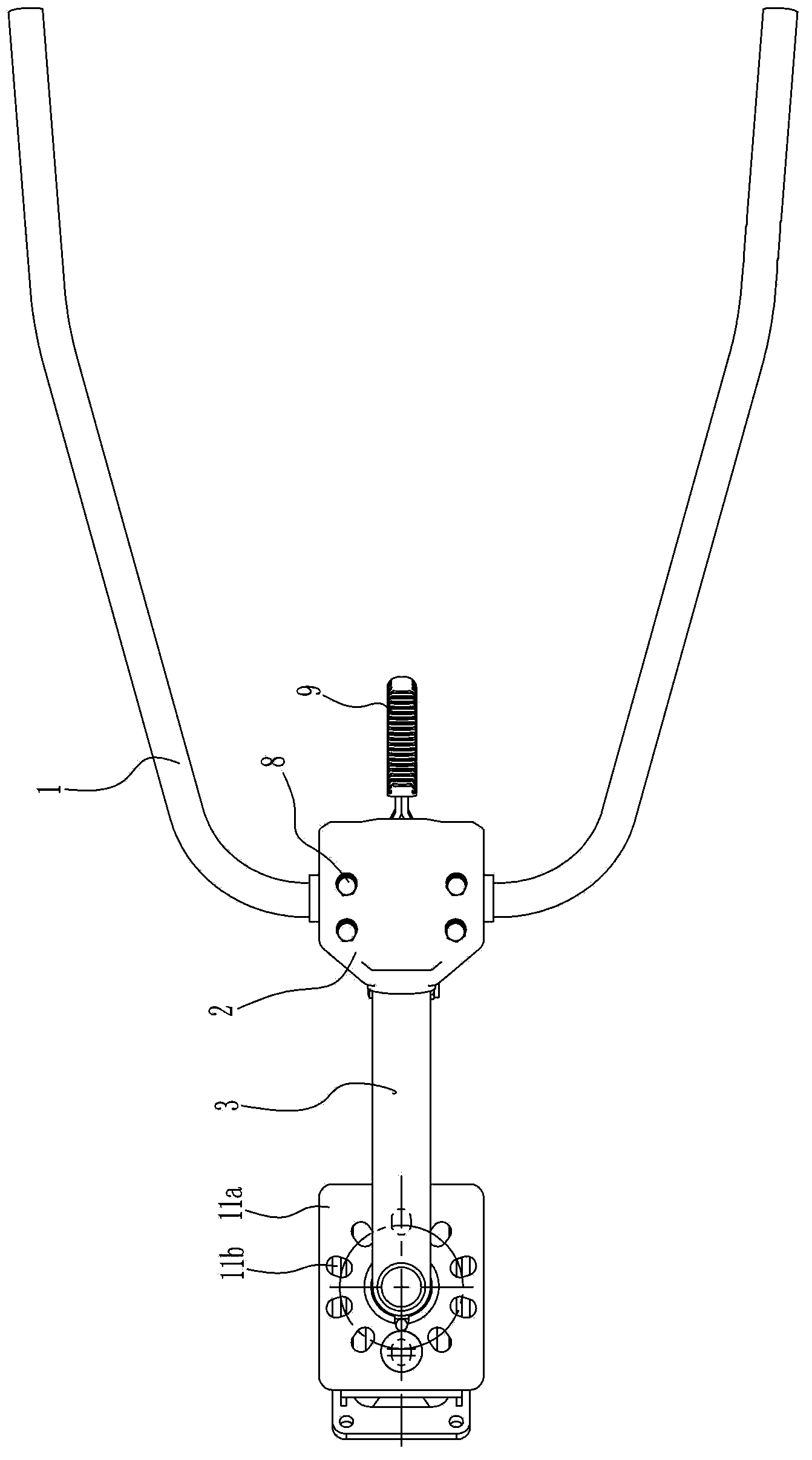

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0020] Such as figure 1 , figure 2 As shown, the armrest frame 1 is a "U" shape with a closed front end and an open rear end, which is formed by bending a round tube. The width of the armrest frame 1 gradually increases from front to back; And the rear end of the armrest frame 1 is bent downward, and the specific angle of bending is determined according to actual needs. The transverse section of the front end of the armrest frame 1 passes through the protective cover 2, and the transverse section of the front end of the armrest frame 1 is hinged to the protective cover 2 through two U-shaped bolts arranged side by side on the left and right sides. The top surface of cover 2 is locked by cap nut 8, and guard cover 2 is fixedly arranged on the tail end of armrest seat 3 by welding.

[0021] Such as figure 1 , figure 2 As shown, a toothed plate 4 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com