Rim roll forming machine with three-dimensional adjusting function

A three-dimensional adjustment and functional technology, applied in metal rolling and other directions, can solve the problems of inconvenience and lack of arbitrary angle adjustment in three-dimensional space, and achieve the effects of preventing waste products, improving efficiency, and expanding the processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

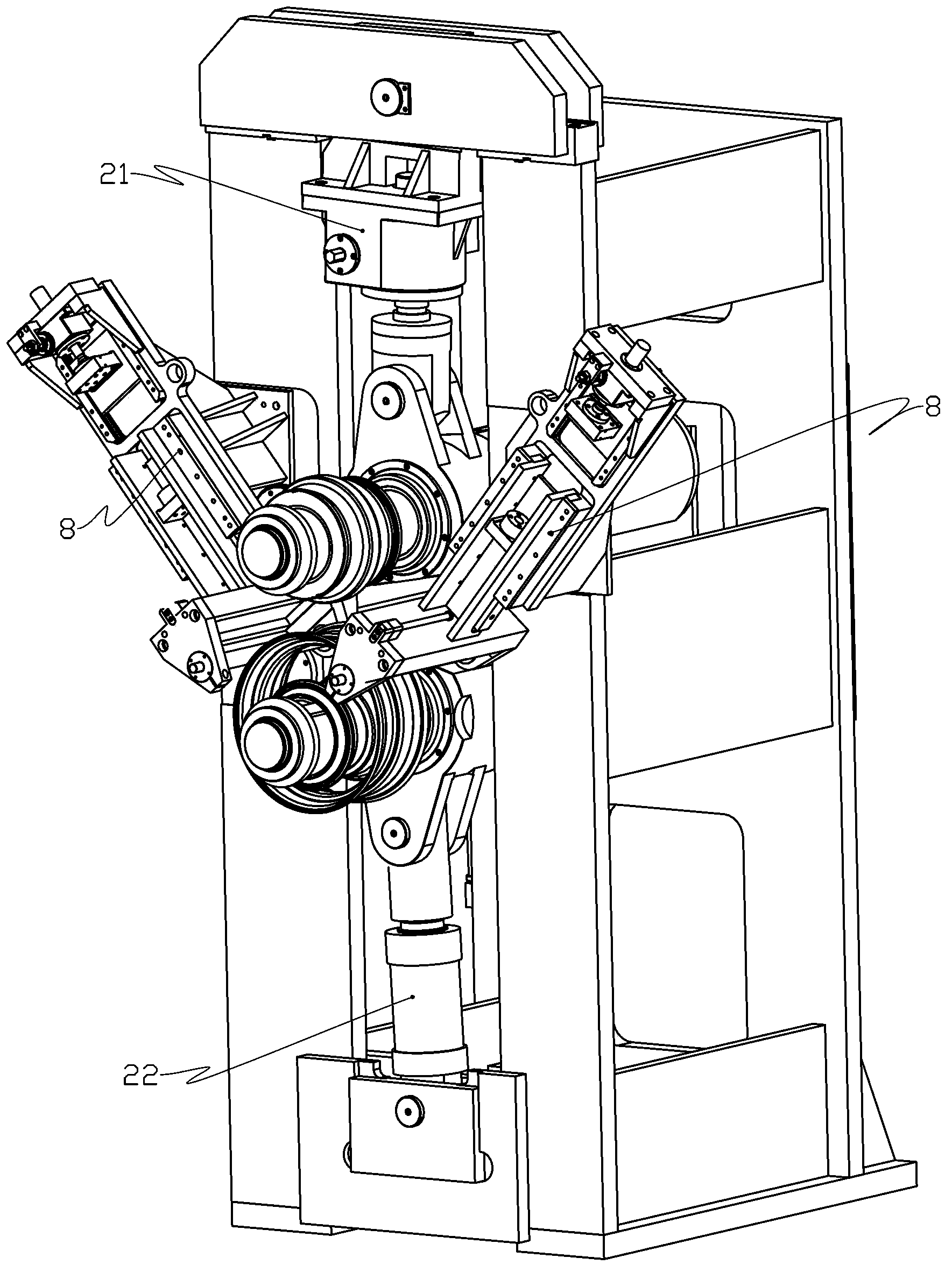

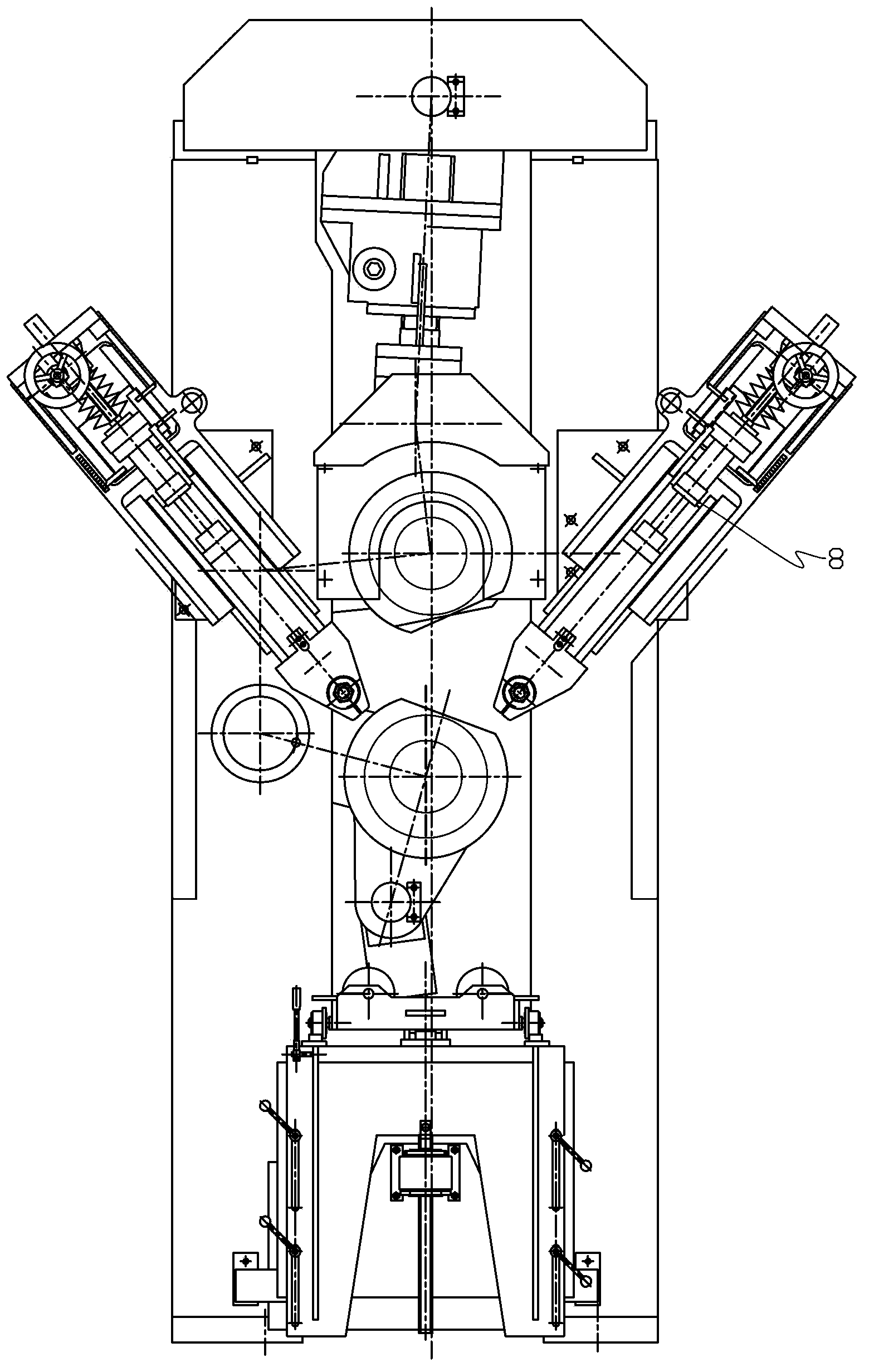

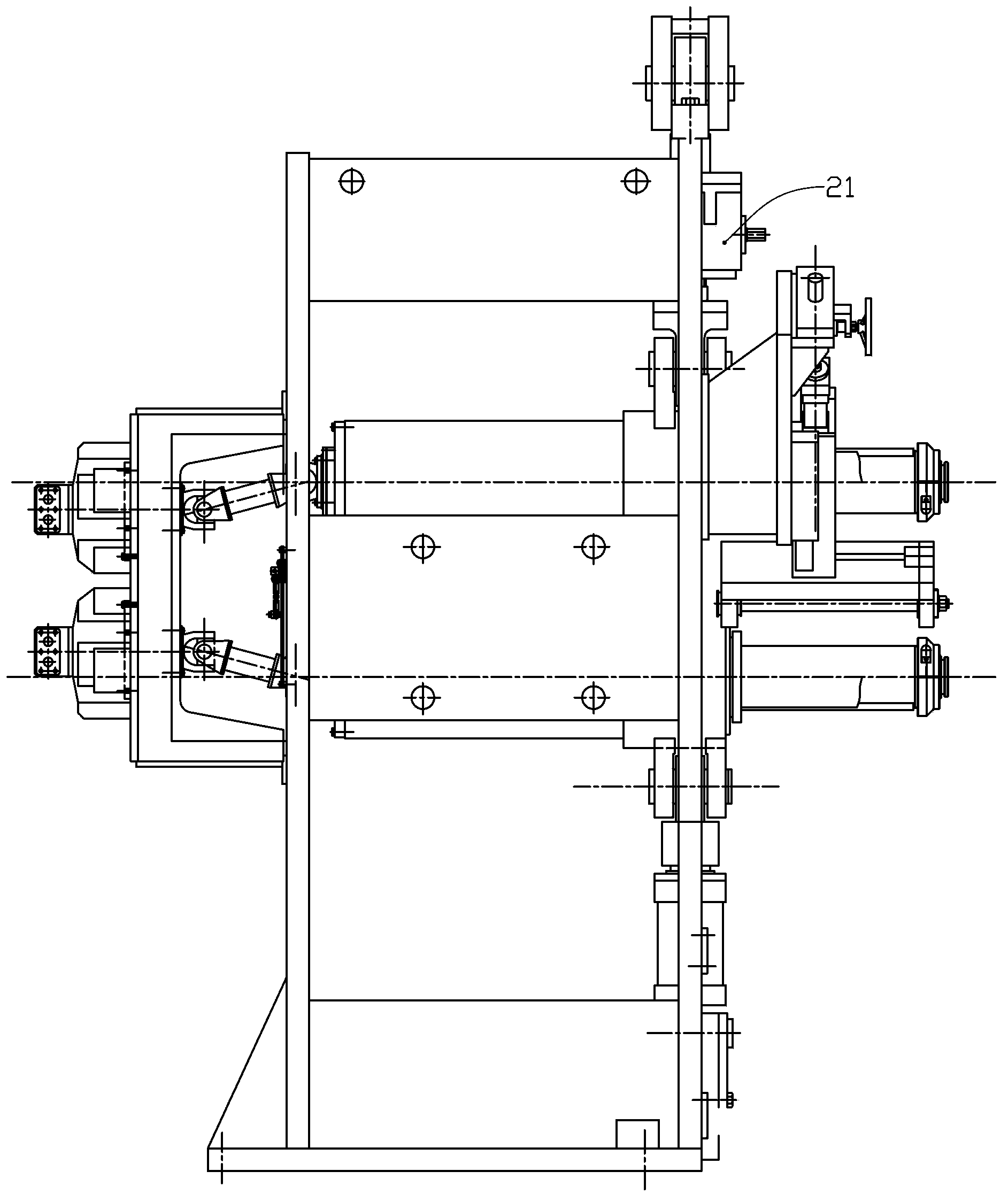

[0036] Such as Figure 1 to Figure 12 , including several major components: body, upper and lower spindle modules, left and right wheel guides, etc. The innovation point of the present invention is described in detail below:

[0037] One of the structural features: the upper and lower two main shafts are inclined to each other at the same time. The angle adjustment mechanism is explained in detail as follows:

[0038] Such as Image 6 , the upper main shaft module includes a first eccentric block 11 , a first hinge shaft 12 , a first main shaft 13 and a first incomplete gear 14 .

[0039]The first eccentric block 11 is a cast iron, in the first eccentric block 11, two first through holes and the second through hole which are arranged in parallel are machined, and the first hinge shaft 12 passes through the first through hole and the front end thereof passes through The first joint bearing is installed on the body, the rear end is slip-knotted on the body through the first e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com