Auxiliary device for processing of oblique oil hole

A technology of auxiliary device and oblique oil hole, which is applied in the direction of positioning device, metal processing equipment, metal processing machinery parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

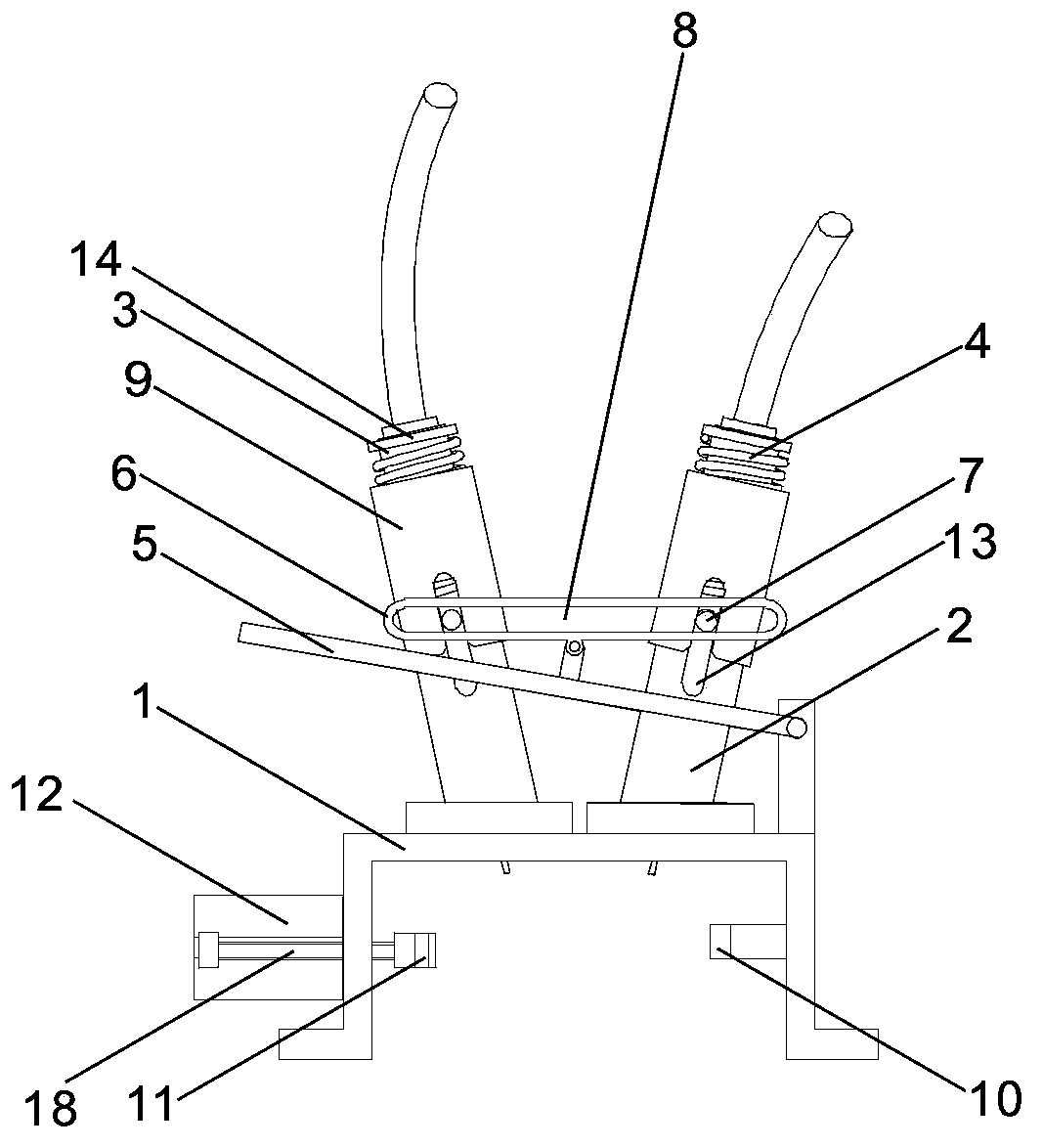

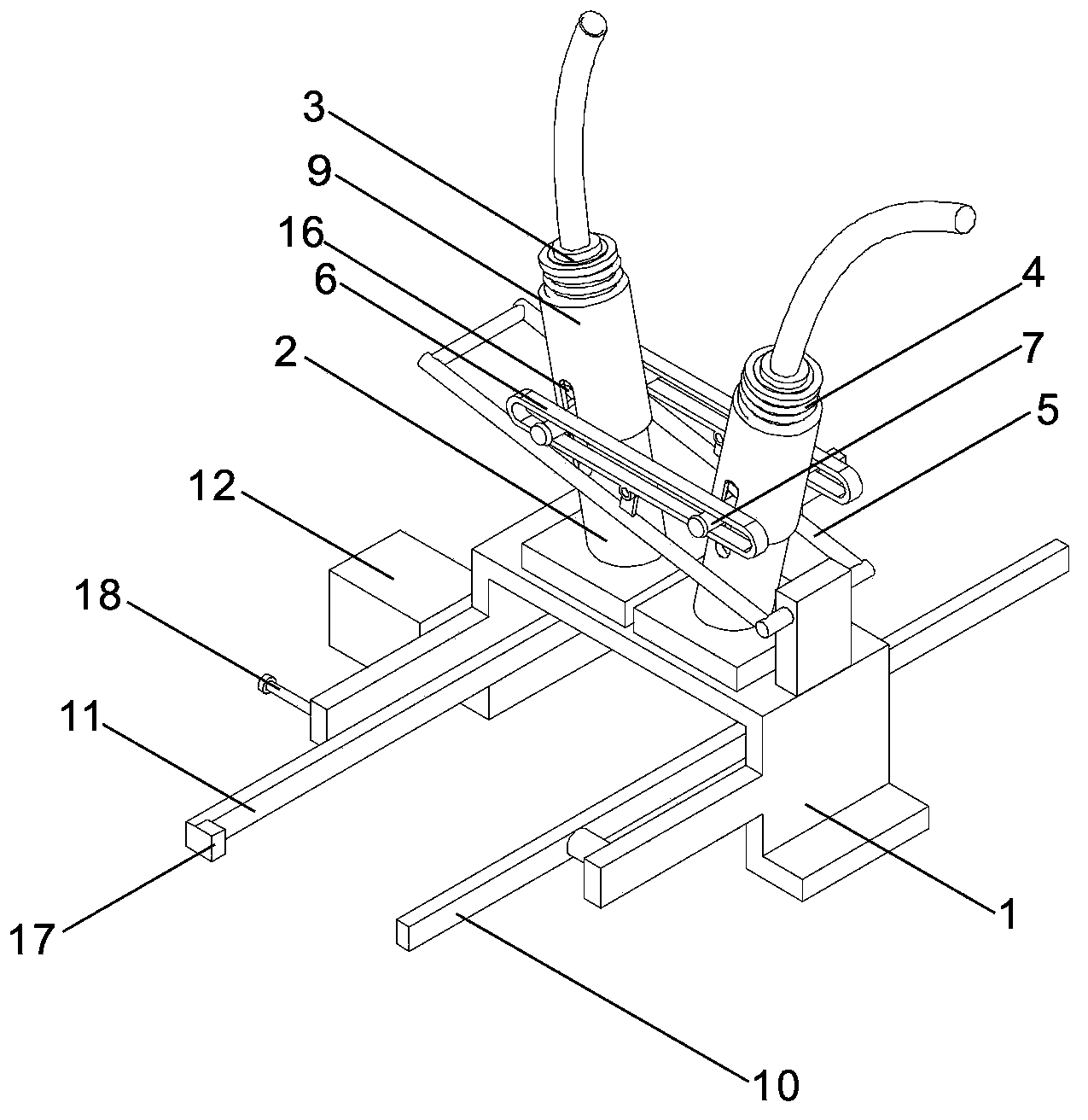

[0025] like figure 1 As shown, an auxiliary device for processing inclined oil holes includes an upper wire support frame 1, a cylindrical drilling tool support sleeve 2, a straight cylindrical drilling tool 3, a return spring 4 and a drilling pressing arm 5, and the drilling tool The support sleeve 2 is obliquely fixed on the upper line support frame 1, and the upper line support frame 1 is provided with a through hole, which communicates with the drilling tool support sleeve 2, and the drilling tool 3 is slidably arranged in the drilling tool support sleeve 2 , the return spring 4 is connected between the drilling tool 3 and the drilling tool support sleeve 2, a linkage mechanism is provided between the drilling tool 3 and the drilling pressing arm 5, and the drilling pressing arm 5 rotates with the upper line support frame 1 through a rotating shaft Connection, the upper line support frame 1 is also provided with a workpiece clamping mechanism. The upper line supp...

Embodiment 2

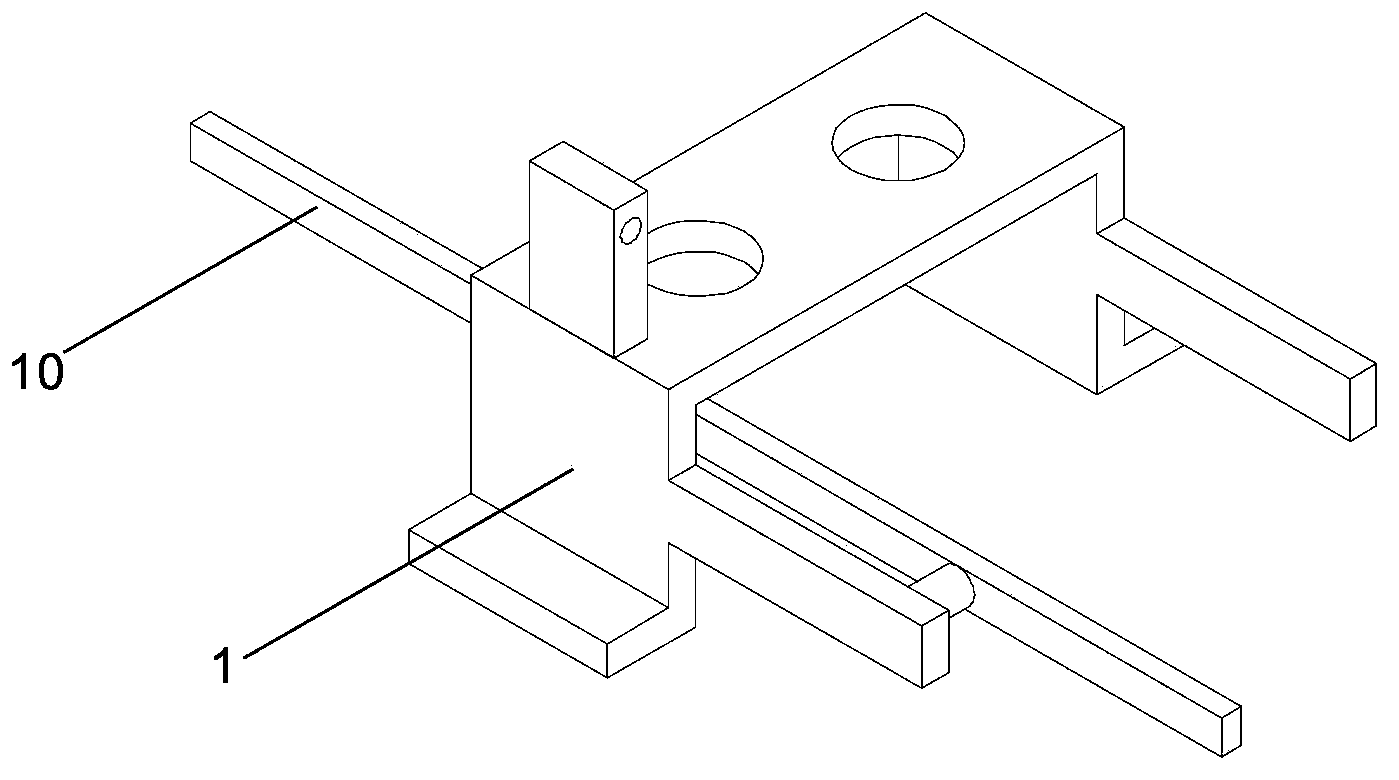

[0028] There are no workpiece arrival sensors and pneumatic stop gauges on the conveying line. One end towards the rear end of the conveying line is provided with a right-angle retaining hook 17 on the moving limit bar 11, such as figure 2 As shown, when the piston rod of the positioning cylinder 12 is retracted, the distance between the end of the right-angle retaining hook 17 and the positioning bar 10 can accommodate the cylinder head workpiece to pass through, and mainly rely on manual positioning of the cylinder head workpiece when the inclined oil hole is processed. During the operation, when the cylinder head workpiece reaches the upper line support frame 1, the operator pushes the cylinder head workpiece to the moving limit bar 11 and makes the side of the cylinder head workpiece close to the moving limit bar 11, and then keeps the cylinder head workpiece and the moving limit bar 11. Push the cylinder head workpiece forward while the position strip 11 is in clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com