Easily-degradable and environment-friendly nylon

An easily degradable and environmentally friendly technology, applied in the nylon field, can solve the problems of insufficient degradable and environmentally friendly properties of polyamide fibers, and achieve the effect of excellent degradable and environmentally friendly properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

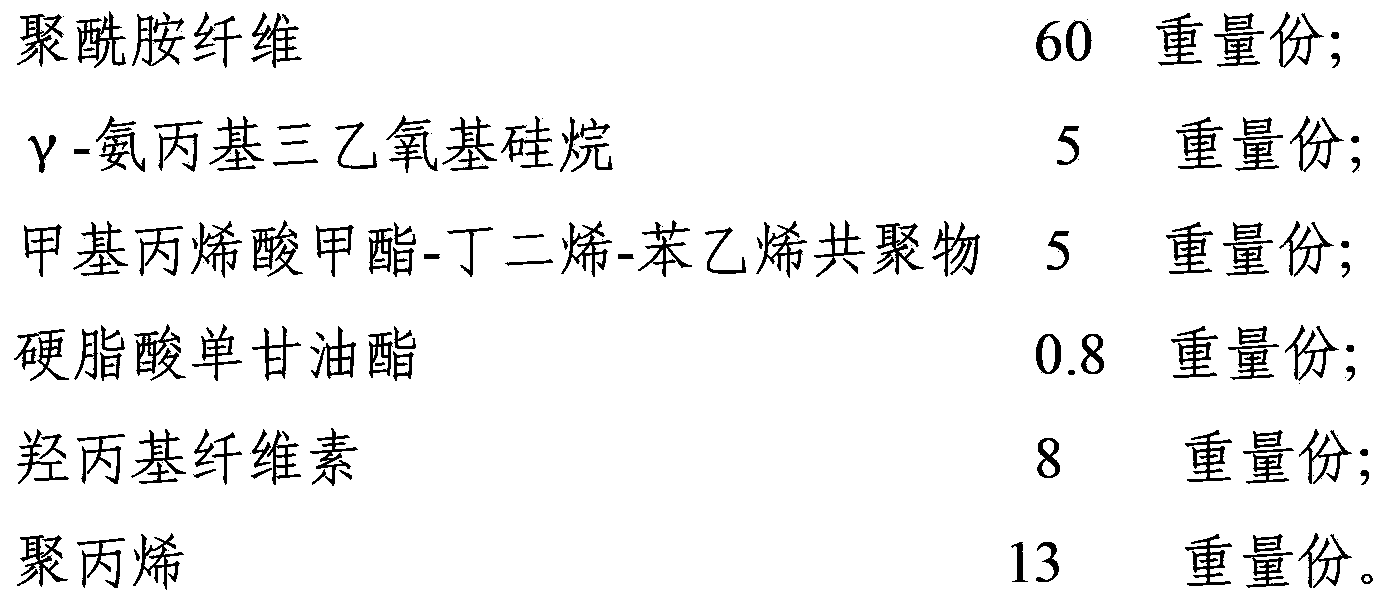

Embodiment 1

[0016] Weigh 600 grams of polyamide fiber and dry it at 90°C for 4 hours, then mix it with 80 grams of hydroxypropyl cellulose, 130 grams of polypropylene, 50 grams of γ-aminopropyl triethoxysilane, methyl methacrylate- 50 grams of butadiene-styrene copolymer and 8 grams of monoglyceride stearate were stirred for 5 minutes at 1100 rpm in a high-speed mixer, and released after being uniform. Put the mixed material into the twin-screw extruder with a length-to-diameter ratio (L / D) of 40. The processing temperature of the twin-screw extruder: the temperature in the first zone is 180°C, the temperature in the second zone is 185°C, and the temperature in the third zone is 180°C. The temperature of the fourth zone is 195°C, the temperature of the fourth zone is 210°C, the temperature of the fifth zone is 215°C, the temperature of the sixth zone is 225°C, the temperature of the seventh zone is 235°C, the temperature of the eighth zone is 240°C, and the speed of the main engine is 320 ...

Embodiment 2

[0018] The easily degradable environment-friendly nylon was prepared in the same manner as in Example 1, except that hydroxypropyl cellulose was not used.

Embodiment 3

[0020] Prepare easily degradable environmentally friendly nylon in the same manner as in Example 1, except that polypropylene is not used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com