Quick beam lowering method based on bridge synchronous jacking and overall replacement

A simultaneous jacking and bridge technology, which is applied in building maintenance, construction, building construction, etc., can solve the problem of high carrying height of bridges, and achieve the effect of reducing safety hazards, fast and safe, and simple and effective methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

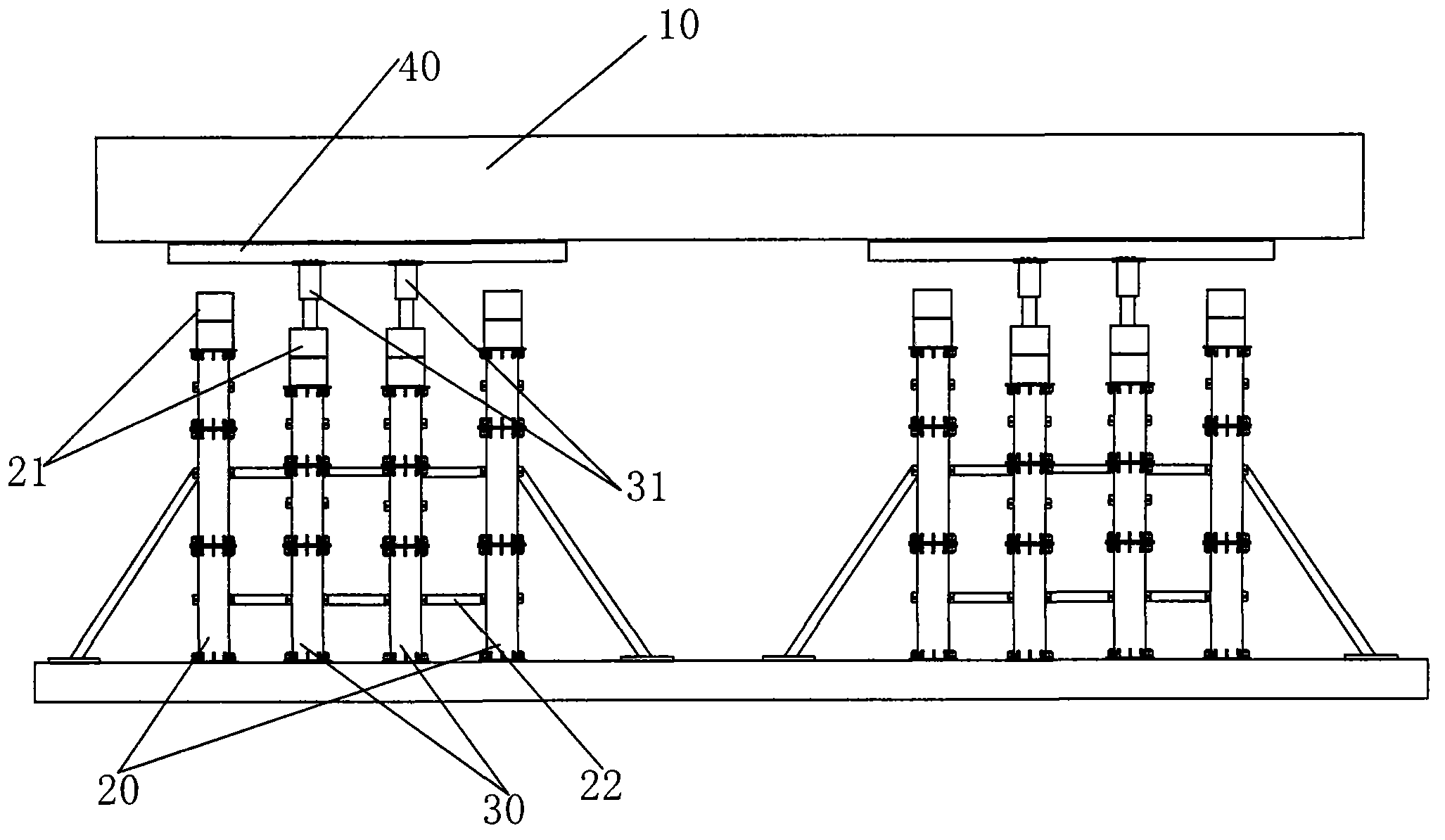

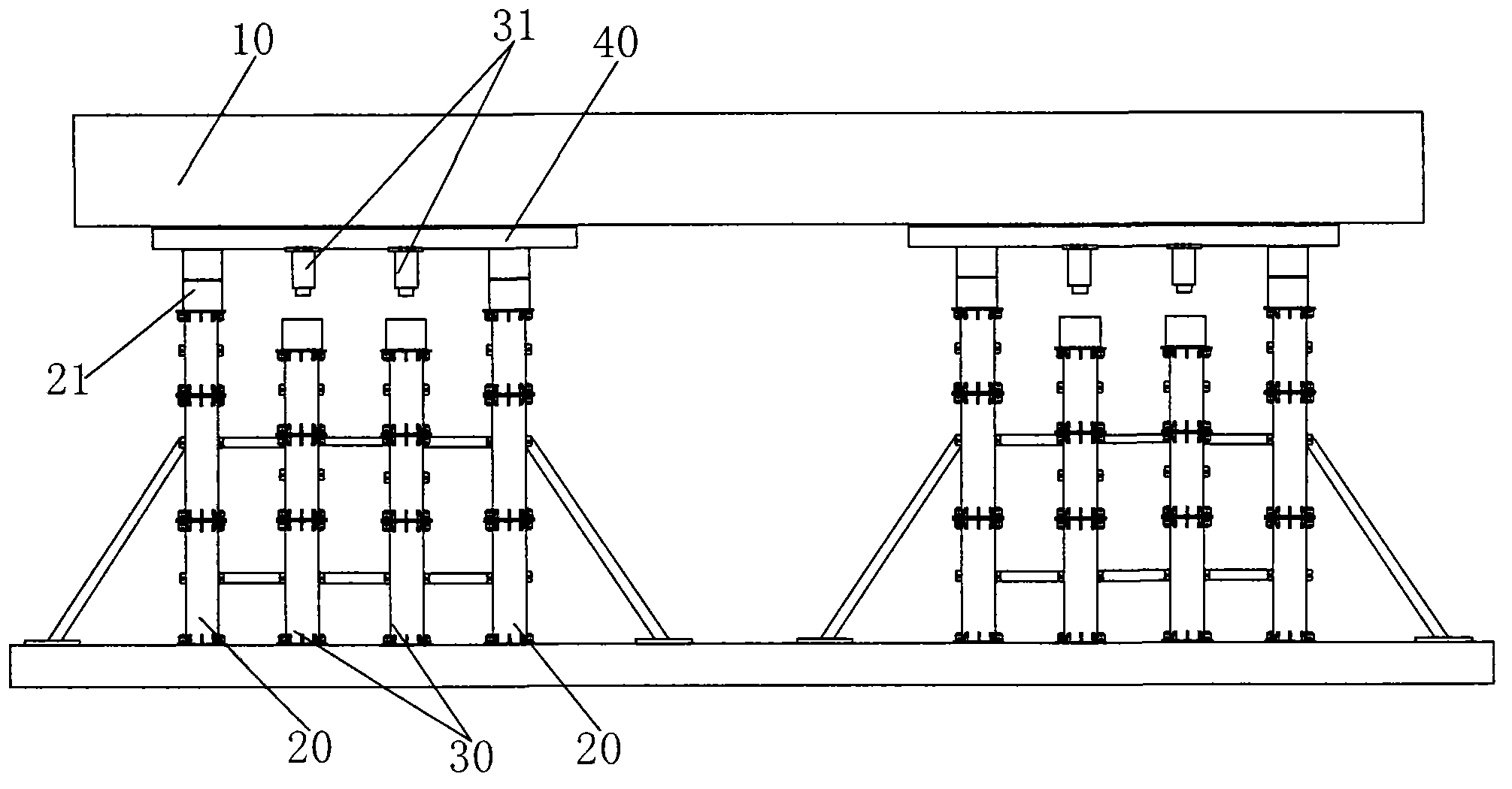

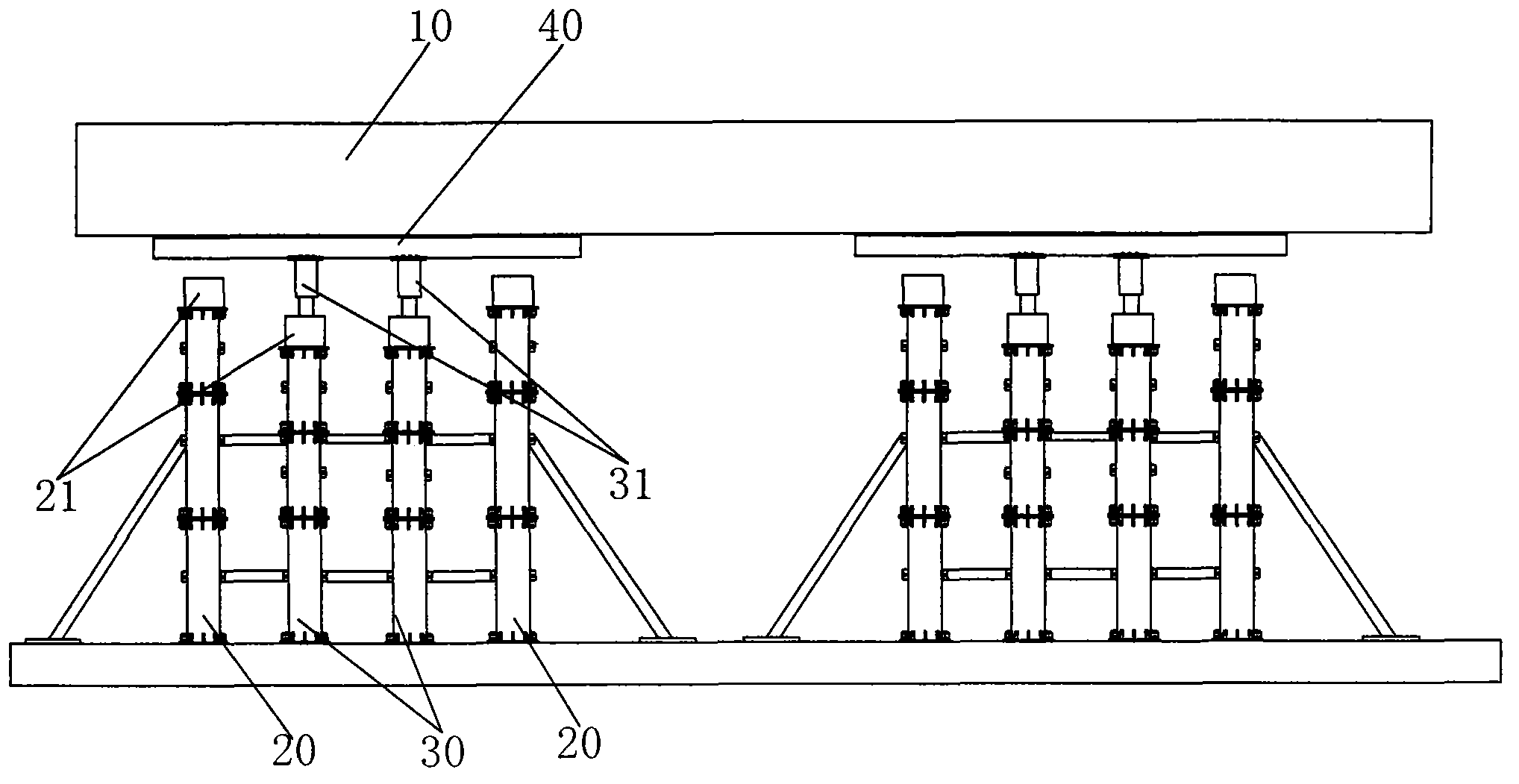

[0025] Such as figure 1 and figure 2 As shown, the rapid beam lowering method based on bridge synchronous jacking and overall replacement first adopts the integrated machine of the carrying frame to lower the bridge 10 as a whole and carry it on the sub-column 20 and the main column 30 with a synchronous jacking device 31 on the top. The sub-column 20 and the main column 30 are multi-segment steel column butt joint structures, and the upper part of the sub-column and the main column is also provided with a spacer 21. 31 to perform synchronous descent of the bridge as a whole.

[0026] The sub-columns and main columns are arranged in a plurality of distributed structures, and two sets of corresponding sub-column and main-column combinations are arranged at both ends of the bridge. Two groups of sub-columns and parent column combinations arranged correspondingly push the bridge through the joists 40 respectively, and a steel connecting beam 22 is connected between each group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com