Hanging type movable working platform for storage tank maintenance

A technology for mobile operation and storage tanks, which is applied in construction, housing structure support, scaffolding supported by housing structure, etc., can solve the problems of high construction cost, long construction time, difficult material transportation, etc., and achieves high safety in use and construction cost. Low, short set-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

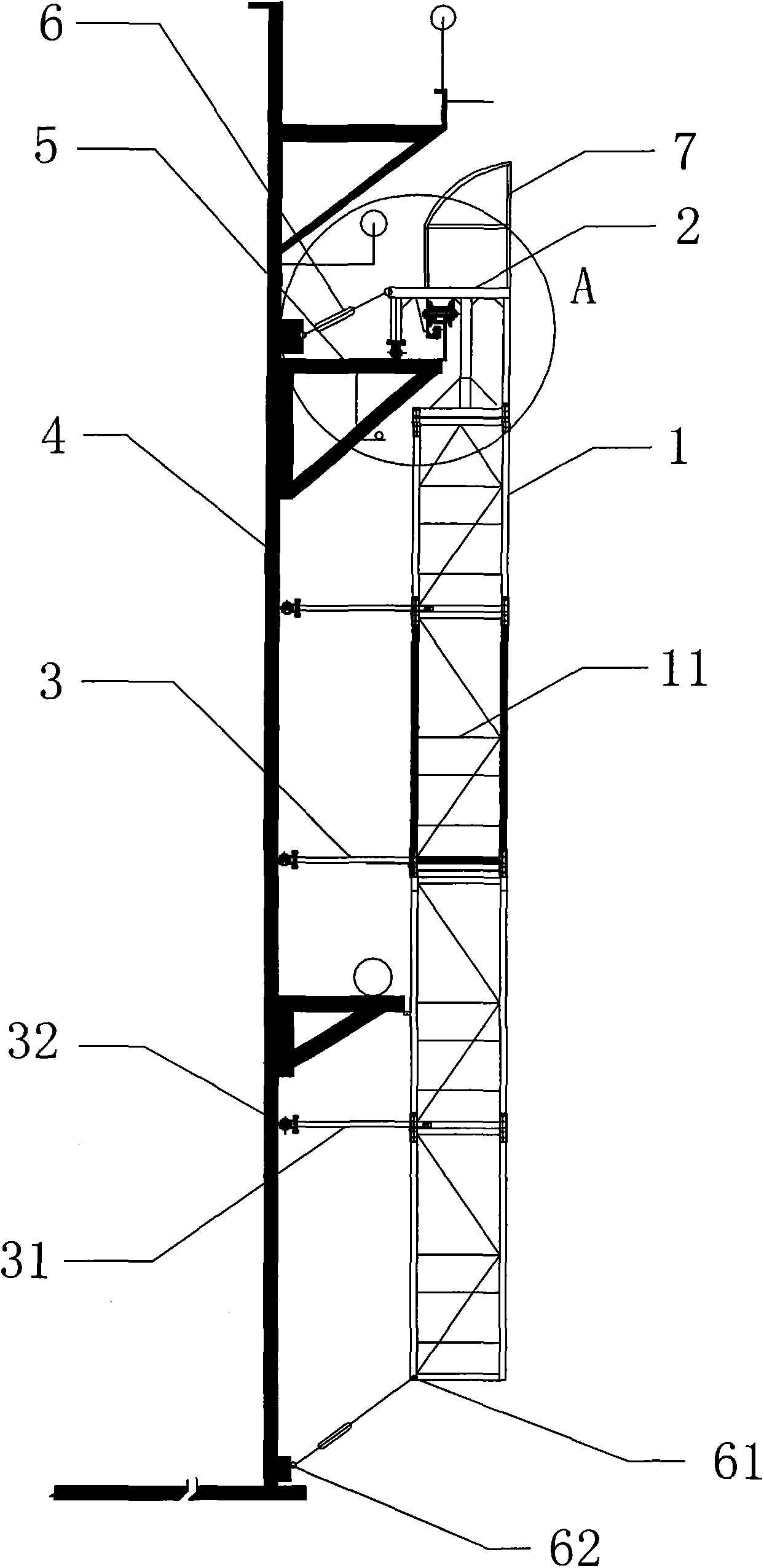

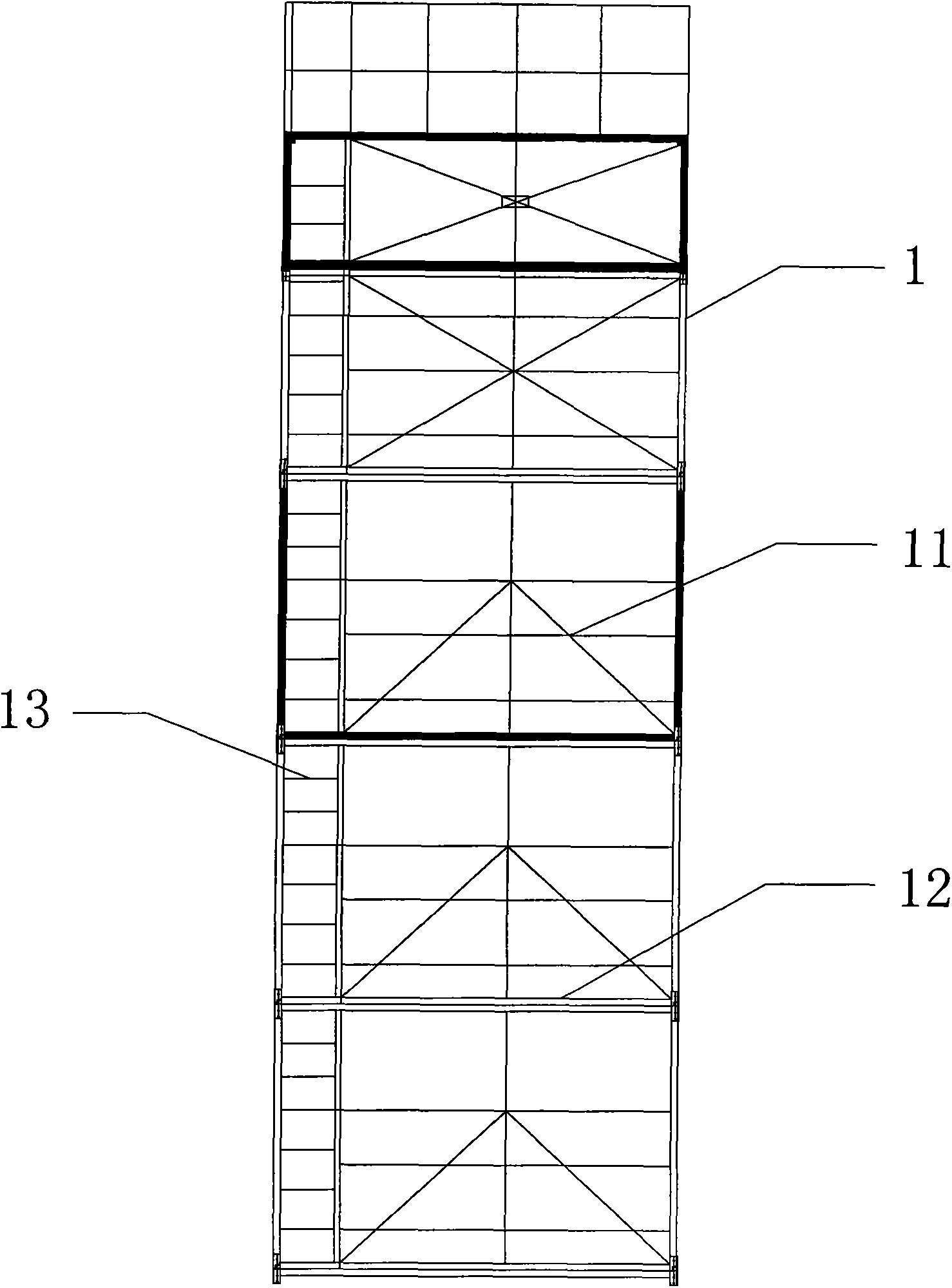

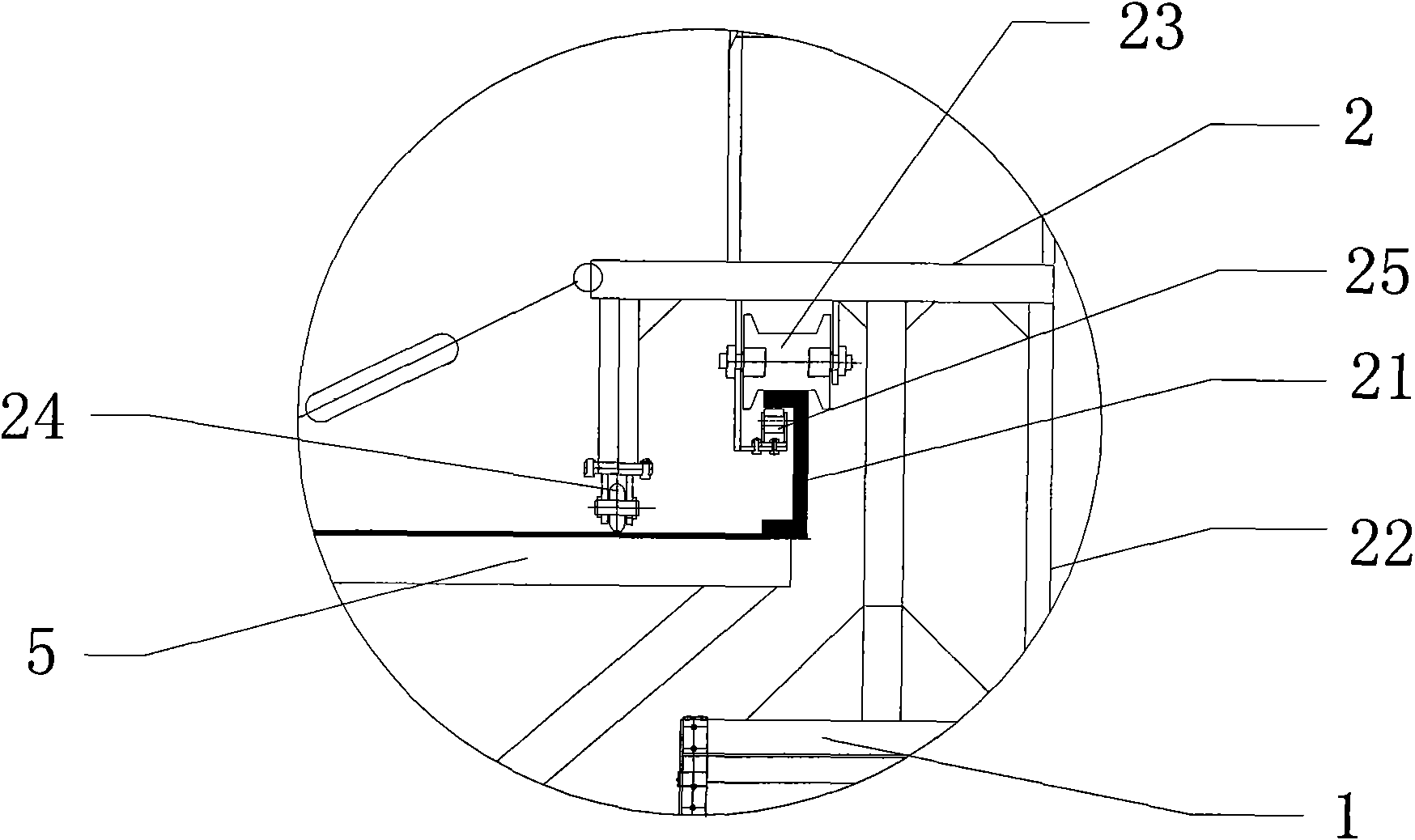

[0018] Such as figure 1 As shown, the special hanging movable work platform for storage tank maintenance of the present invention includes a work hanging basket group 1, a first running mechanism 2 and a second running mechanism 3, and the first running mechanism 2 is arranged on the top of the work hanging basket group 1, And the first traveling mechanism slides relatively on the wind-resistant ring 5 of the storage tank through the pulleys, the second traveling mechanism 3 is arranged on the side of the work hanging basket group 1, and the top of the second traveling mechanism is pressed against the outer wall of the storage tank 4 through the pulleys and relatively sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com