Deformable joining method and deformable joining structure between masonry wall and metal wall

A metal wall, metal technology, applied in the direction of walls, building components, building structures, etc., to achieve the effect of saving materials, installation specifications, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

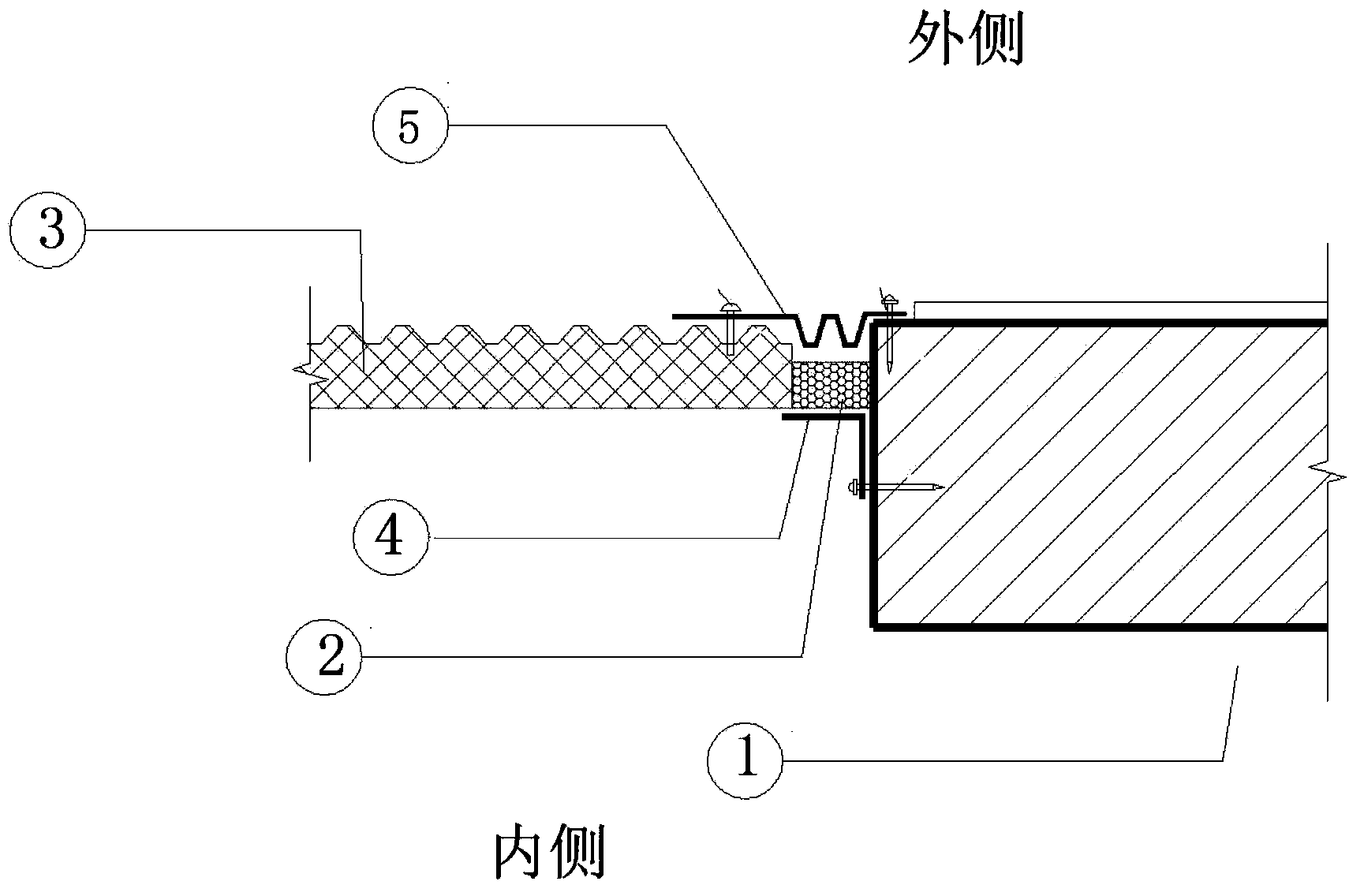

[0026] The present invention will be further described below in conjunction with the drawings.

[0027] During construction, the following steps can be implemented from the inside to the outside:

[0028] (1) The outer side of the metal wall 3 and the outer side of the masonry wall 1 are arranged in a straight line.

[0029] (2) Clean up the surface floating soil, mortar blocks and other debris in the base layer of the wall and the joints. The sedimentary blocks left by the mortar during the construction process are cleaned up with an axe, leaving the metal wall 3 and the masonry wall 1 For the seam between, the seam width x is 50mm≤x≤200mm to prepare for the next process.

[0030] (3) Use measuring and pay-off tools to draw out the control line to ensure the accuracy of the control line.

[0031] (4) Fix the first metal plate 4 on the inner side of the metal wall 3 and adjacent to the inner side of the masonry wall 1. The first metal plate and the inner side of the masonry wall 1 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Seam width | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com