An elliptical tube machine

An elliptical and tube machine technology, applied in metal extrusion, metal processing equipment, manufacturing tools, etc., can solve the problems of poor forming effect, easy damage of forming part, complex structure of forming mechanism, etc., achieve good forming quality, reduce wear, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

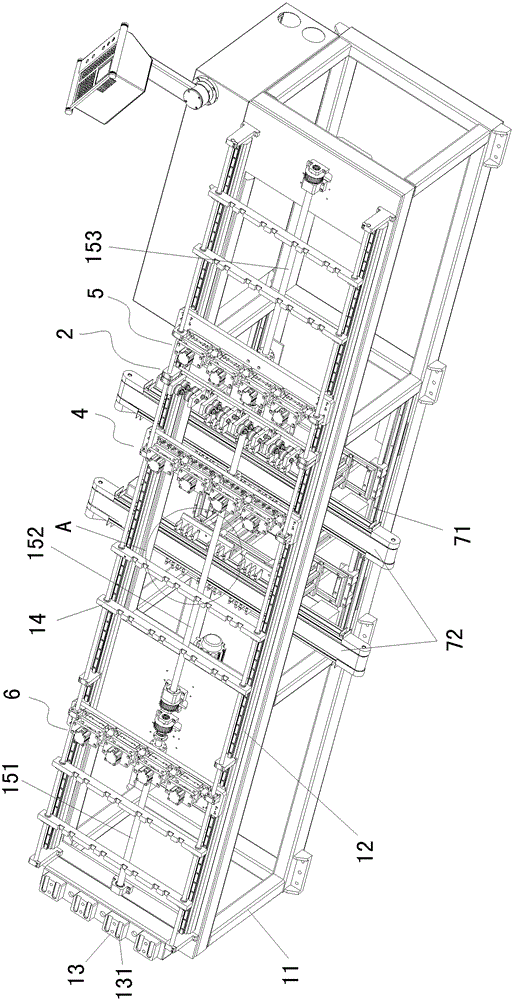

[0025] Below in conjunction with accompanying drawing, the present invention is described in detail:

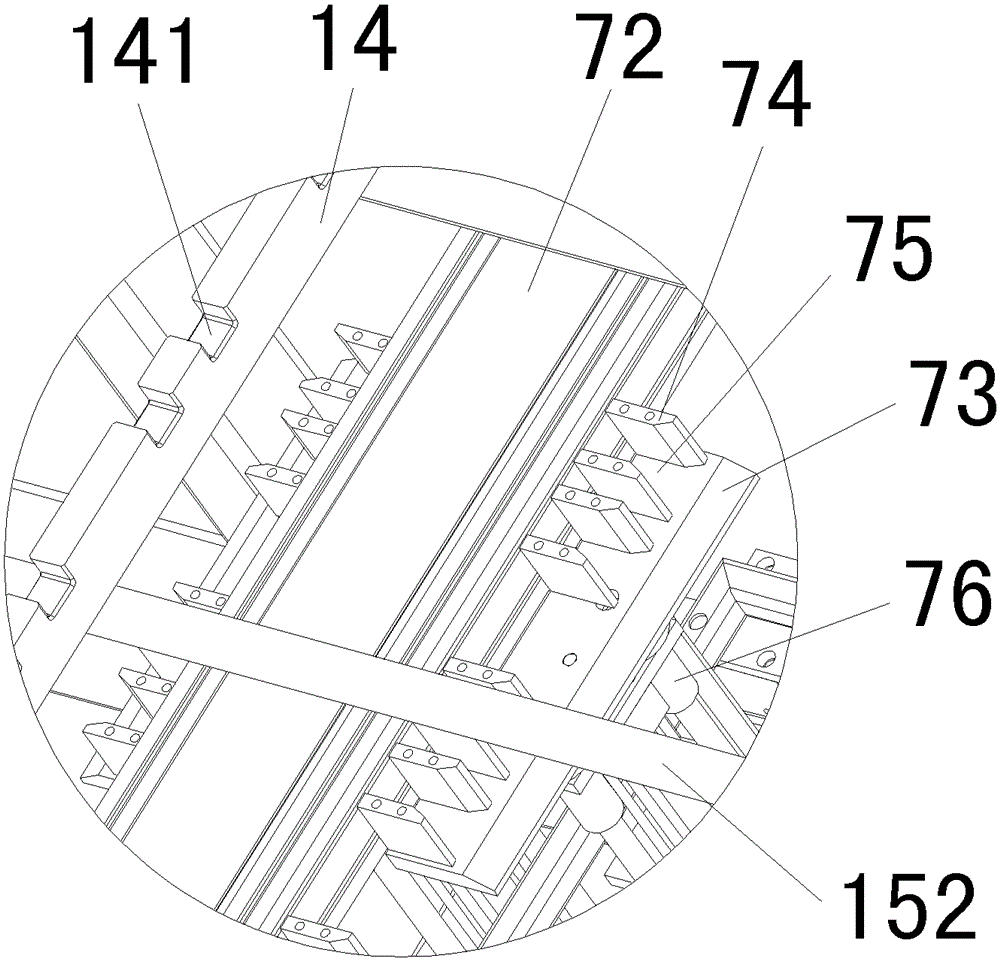

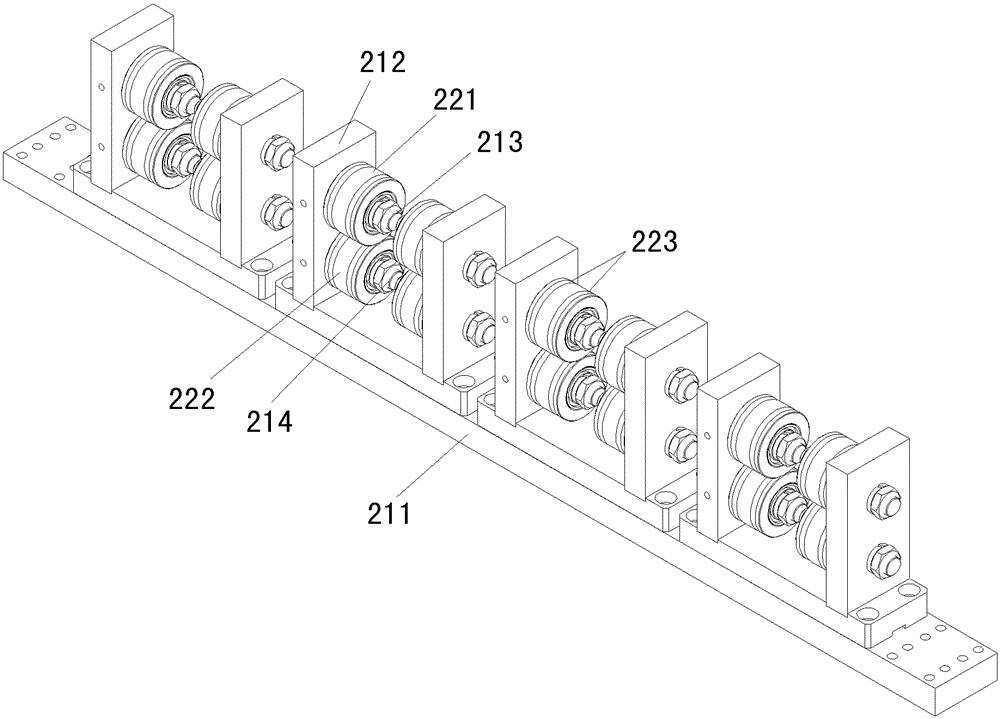

[0026] The present invention comprises frame 11, and frame 11 is provided with guide rail 12, and the front end of guide rail 12 is equipped with charging rack 13, and charging rack 13 is provided with some U-shaped positioning slots 131 for placing U-shaped pipes, and on guide rail 12, The first conveying mechanism 6, the second conveying mechanism 4 and the third conveying mechanism 5 are installed, and the forming mechanism 2 is fixedly installed between the second conveying mechanism 4 and the third conveying mechanism 5, and the forming mechanism 2 is provided with an oval forming hole 23 , the first conveying mechanism 4 clamps the U-shaped tube from the loading rack and sends it to the second conveying mechanism 4, and the second conveying mechanism 4 and the third conveying mechanism 5 successively clamp the U-shaped pipe and drive the U-shaped pipe respectively Throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com