main cooler assembly

A cooler and assembly technology, applied in liquid cooling, engine cooling, machine/engine, etc., can solve problems such as unreasonable design of the main cooler assembly, unreasonable exhaust channel design, and unsatisfactory cooling performance. Achieve compact structure, good heat dissipation effect, and prevent water vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

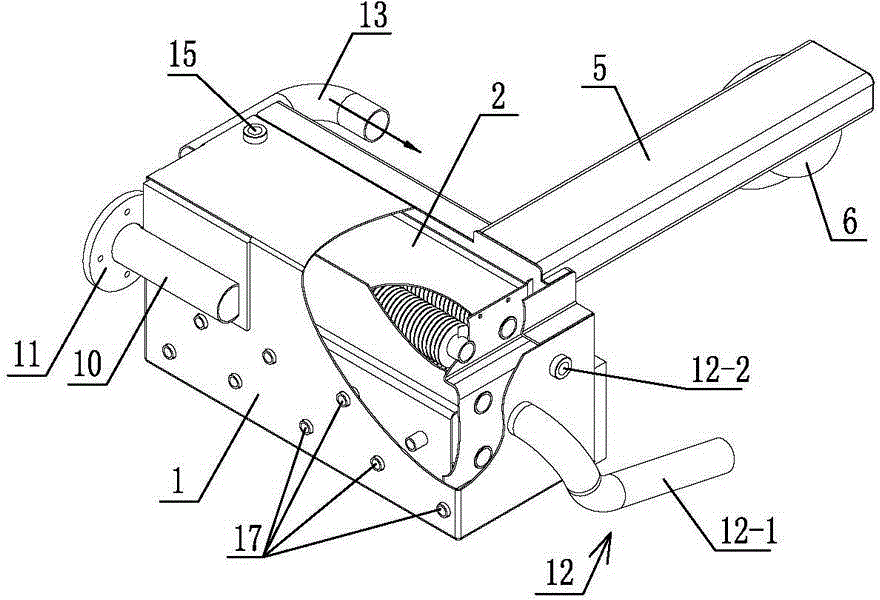

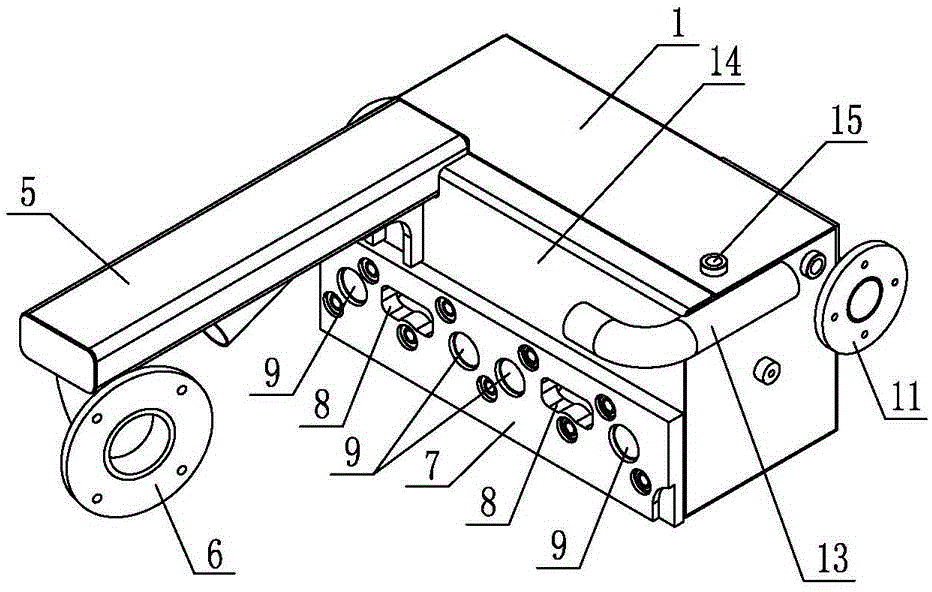

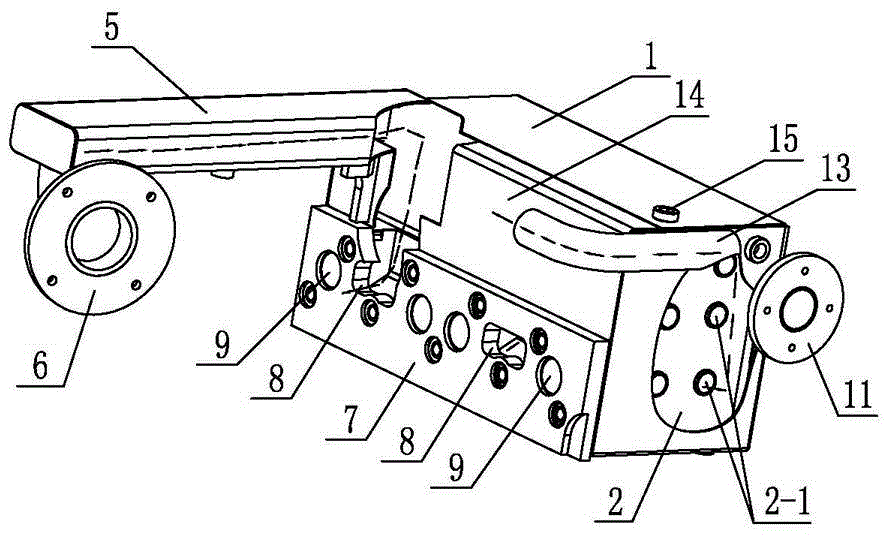

[0030] Such as Figure 1-Figure 12 As shown, this embodiment includes an airtight casing 1 and an exhaust heat exchange chamber 2 located in the casing. A gap is reserved between the casing 1 and the exhaust heat exchange chamber 2 and filled with cooling water to form water. The interlayer 3 cools the temperature of the outer surface of the exhaust heat exchange chamber 2 while cooling the exhaust temperature, and finally the temperature of the outer surface of the main cooler assembly also meets the standard requirements when the exhaust temperature drops to the standard requirements.

[0031] A sealing plate 14 is installed on one side of the housing 1 and an air passage 4 is formed between the two, the air inlet end of the air passage is sequentially connected with the air inlet pipe 5 and the inlet flange 6 positioned outside the housing 1, and the air outlet end Connect the intake and exhaust flange 7, which has two exhaust ports 8 for connecting with the engine air inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com