Hall element testing apparatus

A Hall element and testing device technology, applied in the direction of instruments, etc., can solve the problems of troublesome measurement, low efficiency, and low accuracy, and achieve the effects of improving testing efficiency, convenient use, and avoiding repeated disassembly and assembly of wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

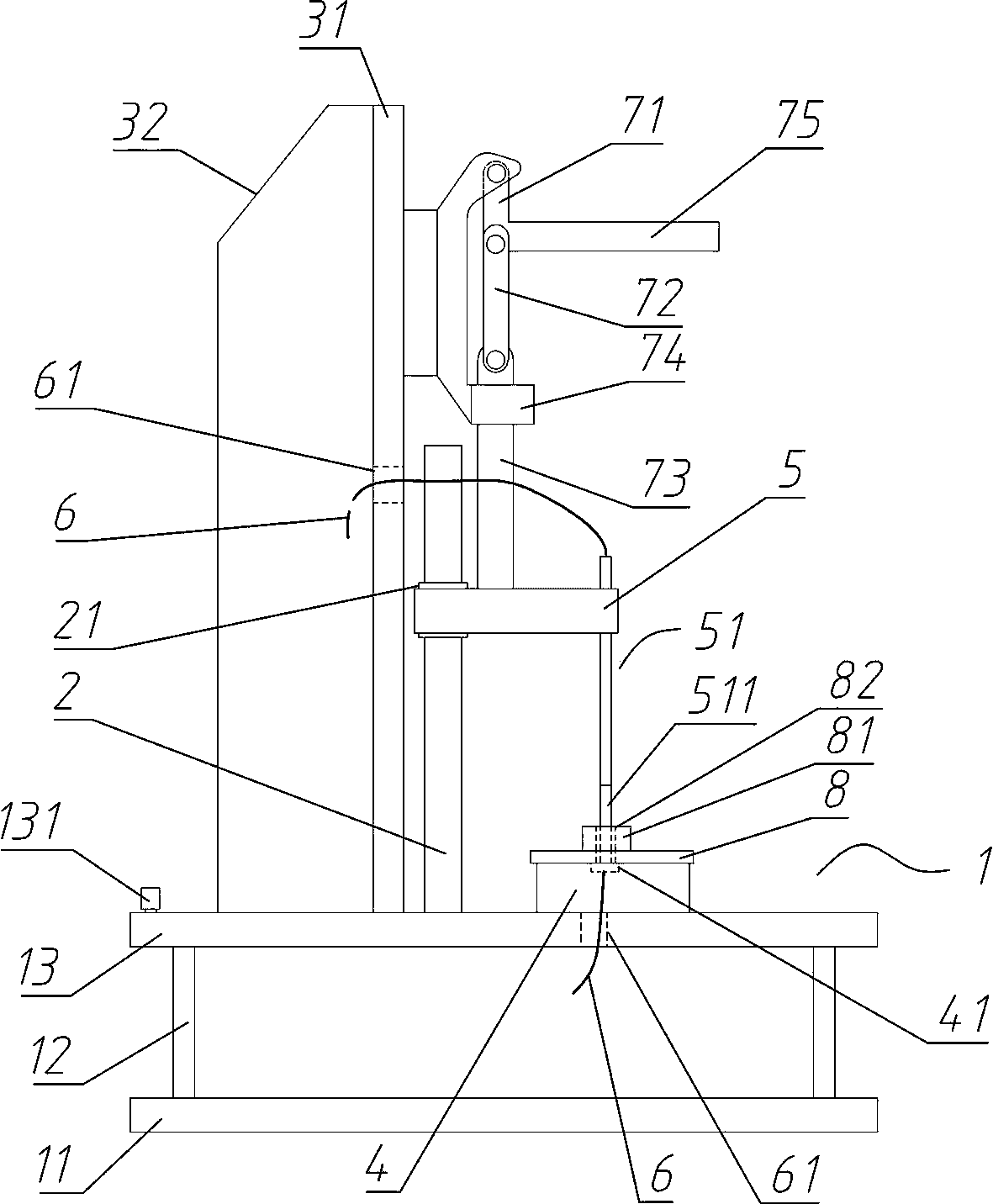

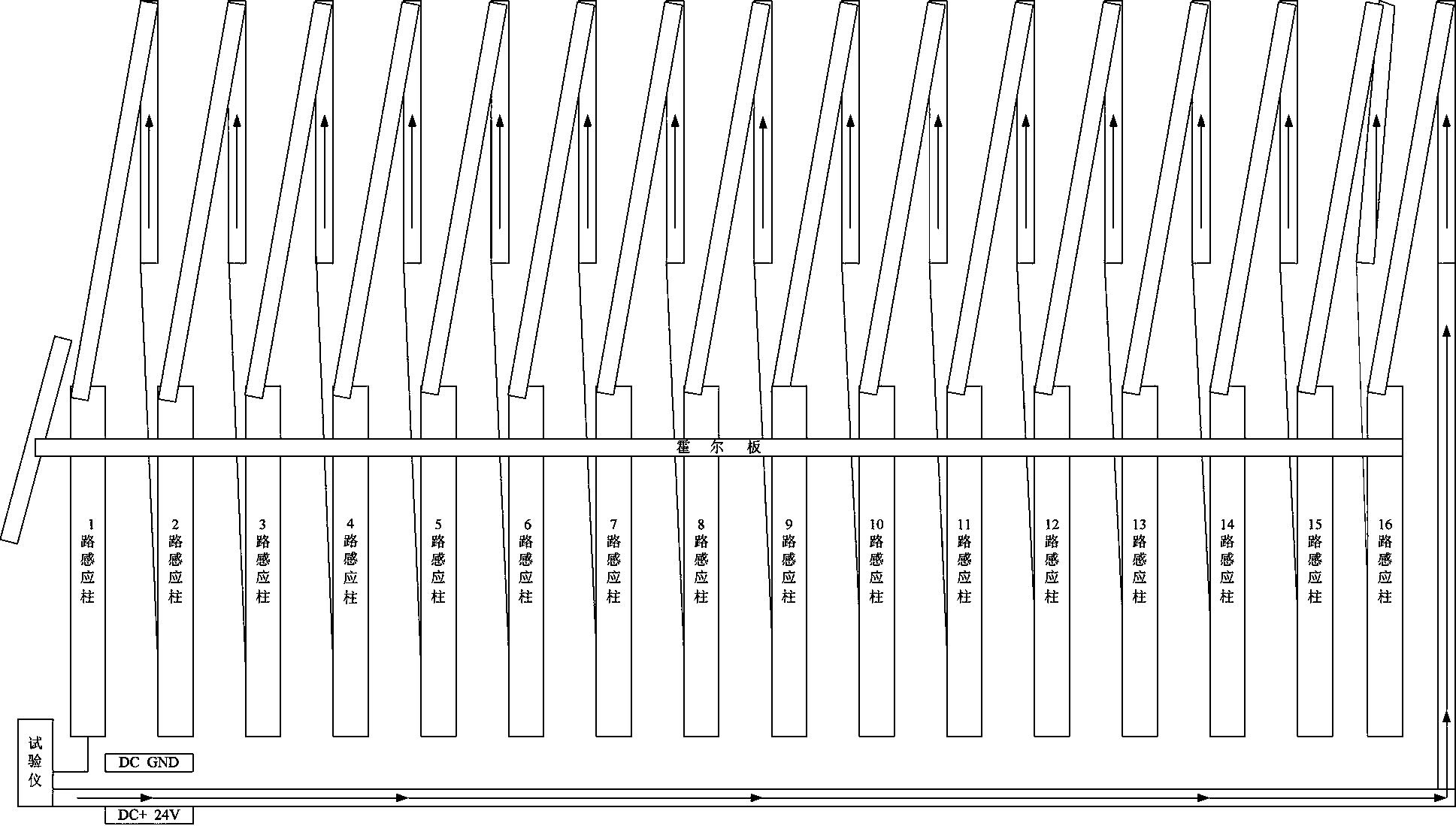

[0015] An embodiment of the Hall element testing device of the present invention is as Figure 1~Figure 2 As shown, it is used to test the Hall plate 8 with sixteen Hall elements 81 arranged in the same line, including a device frame, which includes a horizontally arranged base plate 1 and a vertical plate 31 perpendicular to the base plate 1; wherein The bottom plate 1 includes a bottom working plate 13 and a base plate 11. The four corners of the base plate 11 are provided with pillars 12 to support the bottom working plate 13 to form an isolated space, which is convenient for the laying and hiding of the wires 6, making the whole more concise and beautiful; Ribs 32 are connected to the side, which can ensure the overall stability of the device frame.

[0016] The Hall element testing device also includes a moving contact seat 5 and a static contact seat 4 made of insulating and transparent acrylic material. The bottom working plate 13 is provided with a guide column 2 exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com