A separate photoelectric control device that can be installed separately

A photoelectric control, separate technology, applied in the direction of measuring device, lubrication indicating device, engine lubrication, etc., can solve the problems of consuming the material to be measured, increasing the installation time and material cost, and poor system identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

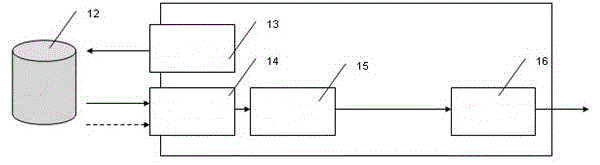

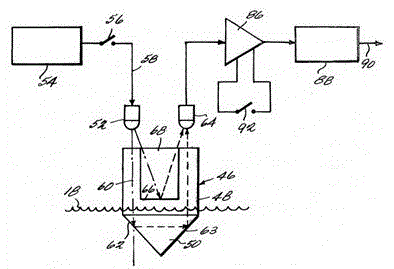

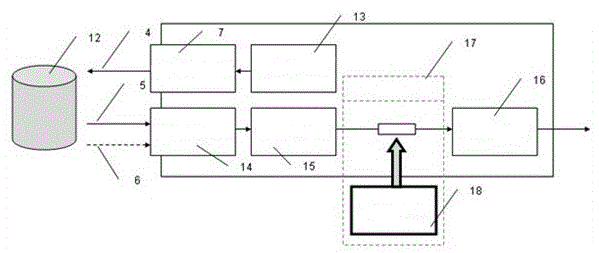

[0033] Such as image 3 Shown is an embodiment of the present invention, wherein the signal processing unit includes a light emitting module 13 , a light receiving module 14 , a signal processing module 15 , and an output circuit module 16 . The above-mentioned light emitting module 13 emits a light signal 4, and the light source passes through a light modulating device 7, which can change the intensity, phase, and luminous field type of light, and other characteristics. When there is no object 12 under test, the light signal 5 will be fed back to light receiving module 14; otherwise, no light signal will return to the light receiving module 14. The signal of the light receiving module 14 will be delivered to the signal processing module 15, and after the signal is processed, it will pass through the analog test unit 17, refer to Figure 4 , which includes an additional trigger signal 18 that can control a switch 22, the switch can be a single-pole double-throw (SinglePoleDou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com