A wire harness rolling production line

A production line and wire harness technology, applied in the manufacture of wire harnesses, electrical components, circuits, etc., can solve the problems of large wire harness gaps, loose twisting of wire harnesses, and no consideration of single twisters, etc., to achieve tight cable and easy rolling And the effect of twisting and eliminating the phenomenon of broken wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

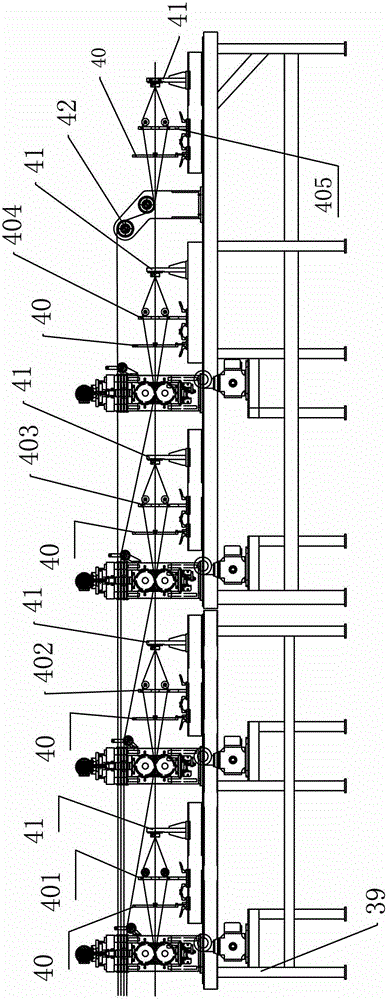

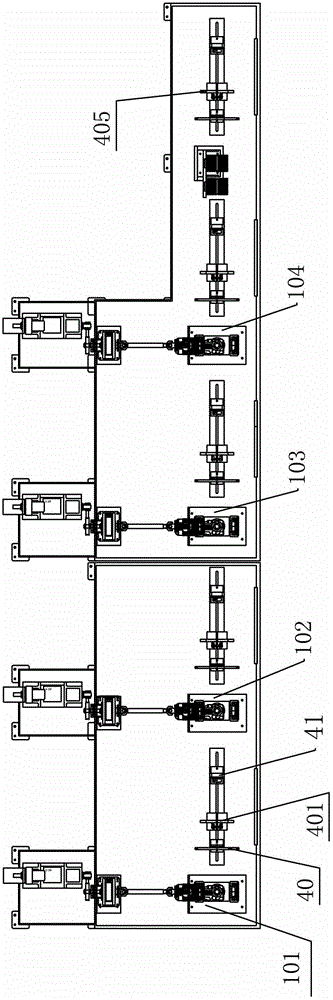

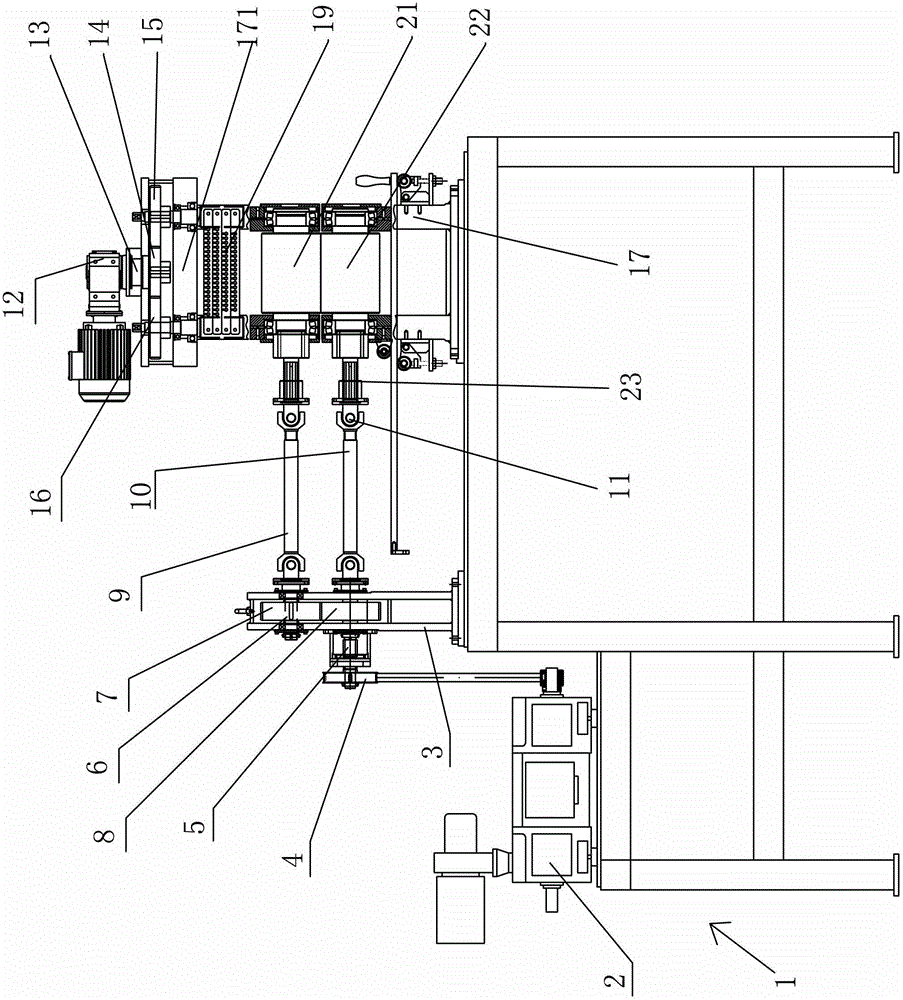

[0050] like Figures 1 to 3As shown, the wire harness rolling production line of the present invention includes: a frame 39 on which four roll forming machines 1 are arranged, and the roll forming machine 1 includes a motor 2 fixed on the frame, an intermediate shaft 5 and The intermediate shaft two 6 is fitted on the front support 3 of the motor 2 through the parallel rotation of the bearing, and the rear end of the intermediate shaft one 5 is provided with a pulley 4, which is connected to the rotor of the electric motor 2 through a belt. The shaft one 5 is fixedly provided with a gear one 8, the intermediate shaft two 6 is fixedly provided with a gear two 7, the gear one 8 meshes with the gear two 7 and the number of teeth of the two gears is equal; the front end of the intermediate shaft one 5 passes through The universal joint is connected to the rear end of the transmission shaft one 10, and the front end of the intermediate shaft two 6 is connected to the rear end of th...

Embodiment 2

[0067] A cable production line, comprising a wire stranding machine and the wire harness rolling production line in the above-mentioned embodiment 1, the wire stranding machine is arranged on the right side of the wire harness rolling production line, and is used to output the wire harness rolling production line The multi-layer core cables are twisted into cables.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com