Cleaning device and process for waste polyester bottle chip

A technology for PET bottle flakes and a cleaning device, which is applied in the directions of using liquid cleaning methods, cleaning methods and utensils, recycling technology, etc. Low corrosiveness and easy recovery of ethylene glycol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

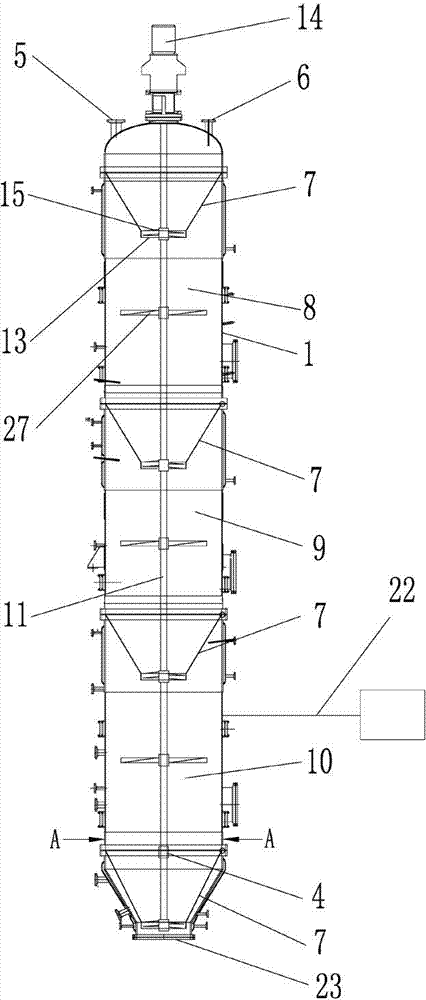

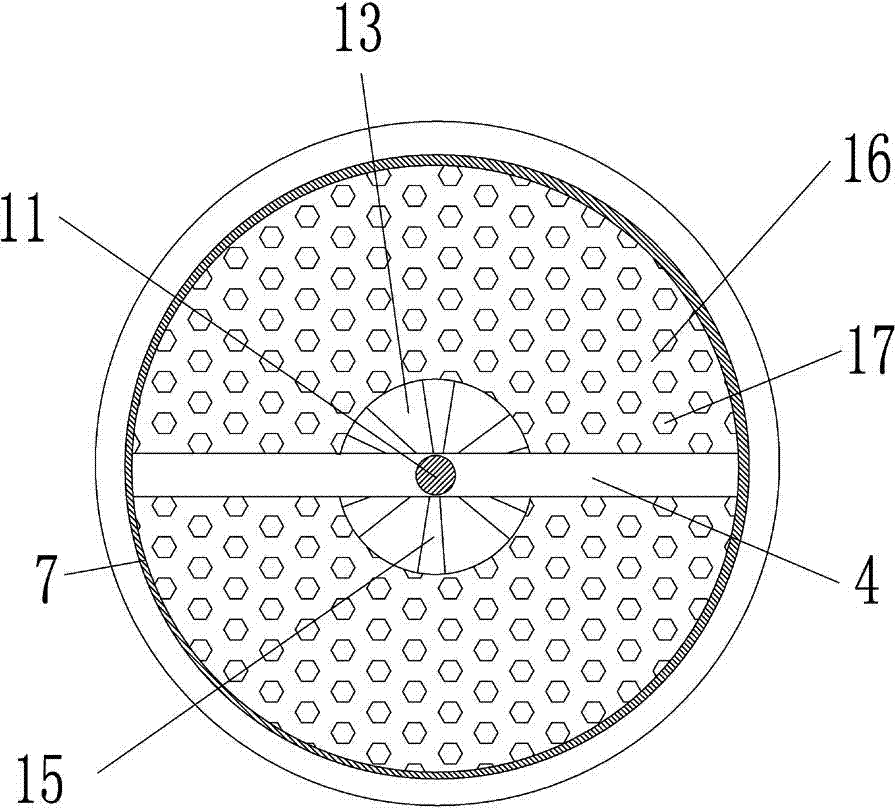

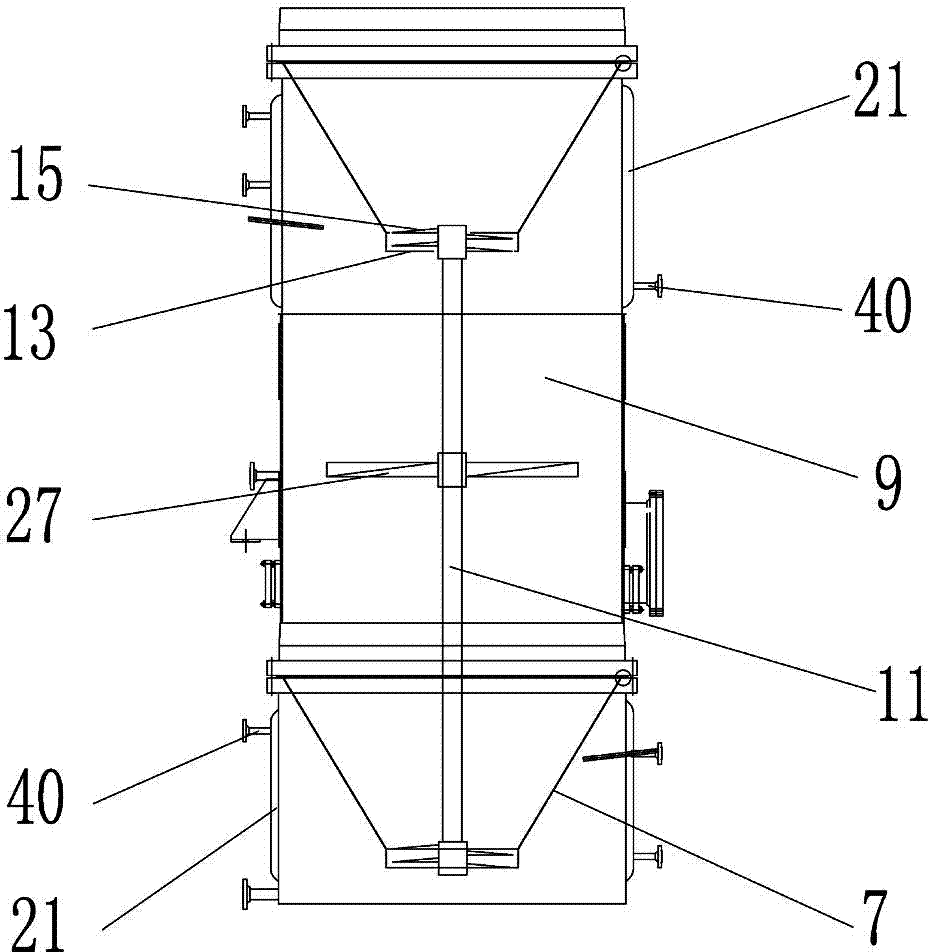

[0038] Combine Figure 1~3 , Waste polyester bottle chip cleaning device: including body 1, the top of the body 1 is provided with a feed inlet 5 and an air outlet 6 respectively; the bottom of the body 1 is provided with a discharge port 23; the body 1 is arranged at fixed intervals from top to bottom At least two redistributors 7, the redistributor 7 divides the body 1 into upper, middle, and lower cavities (8, 9, 10) at intervals; a rotating shaft 11 is provided through each redistributor opening 13, and the upper end of the rotating shaft 11 It is connected to the power unit 14 in transmission, and the lower end is rotatably connected to the supporting device 4 fixed in the body 1; a short stirring blade 15 is provided on the rotating shaft 11 at the opening 13 of each redistributor, except for the rotation at the opening 13 of the redistributor The shaft 11 is provided with a long stirring blade 27; each redistributor 7 is provided with a number of through holes 17; the bo...

Embodiment 2

[0043] The cleaning device for waste polyester bottle flakes has the same structure as that of the first embodiment.

[0044] The cleaning process of waste polyester bottle flakes is different from the cleaning process of Example 1 in that: the temperatures of the upper, middle and lower cavities (8, 9, 10) are respectively: 150℃, 180℃, 210℃, corresponding The residence times are 44, 44, 70, respectively, the ethylene glycol feed rate is 0.32kg / kg·h, and the other steps are the same as the cleaning process steps of Example 1.

[0045] The recovery device of waste polyester bottle flakes has the same structure as that of the first embodiment.

[0046] The difference between the recovery process of waste polyester bottle flakes and the recovery process of Example 1 is that the temperature of the post-alcoholysis reactor 26 is 272° C., the residence time is 75 min, and the other steps are the same as the recovery process of Example 1. .

Embodiment 3

[0048] The cleaning device for waste polyester bottle flakes has the same structure as that of the first embodiment.

[0049] The cleaning process of waste polyester bottle flakes is different from the cleaning process of Example 1 in that: the temperatures of the upper, middle and lower cavities (8, 9, 10) are 180℃, 210℃, 240℃ respectively, corresponding The residence time of, respectively: 30, 30, 55, the ethylene glycol feed rate is 0.54 kg / kg·h, and the other steps are the same as the cleaning process steps of Example 1.

[0050] The recovery device of waste polyester bottle flakes has the same structure as that of the first embodiment.

[0051] The difference between the recovery process of waste polyester bottle flakes and the recovery process of Example 1 is that the temperature of the post-alcoholysis reactor 26 is 290°C and the residence time is 60min, and the other steps are the same as the recovery process of Example 1. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com