Double-end welding bed for carbon-dioxide arc welding

A carbon dioxide and shielded welding technology, applied in the field of welding beds, can solve problems such as low operation efficiency, and achieve the effect of improving work efficiency and good welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

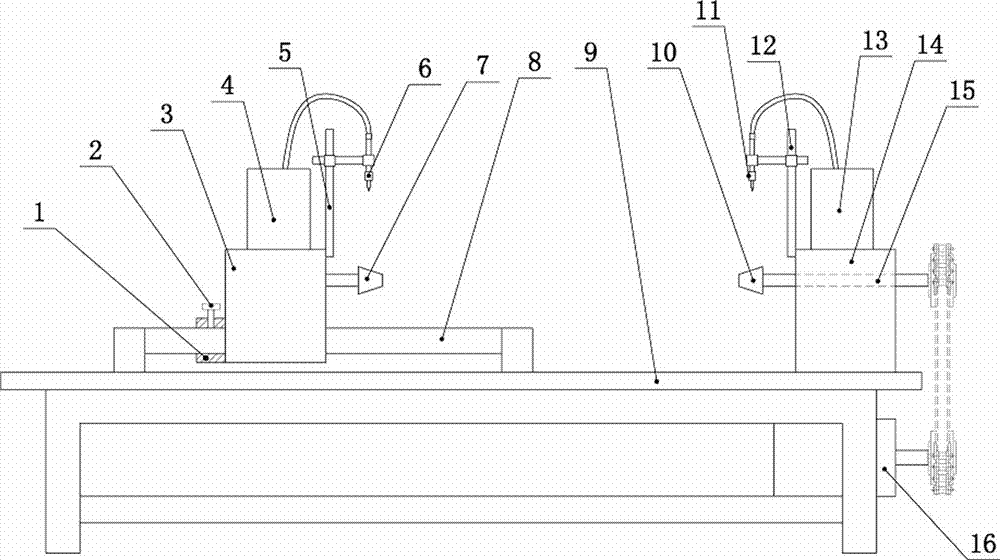

[0011] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0012] A double-headed welding bed for carbon dioxide shielded welding, such as figure 1 Shown, comprise bed frame 9, be fixedly installed with motor 16 and rotating base 14 on bed frame 9, be equipped with rotating bar 15 relatively rotating on rotating base 14, rotating bar 15 is connected with motor 16 transmission, rotating bar 15 left ends are fixedly connected with The right head 10, the left side of the rotating base 14 is fixedly connected with the right support 12, the rotating base 14 is fixedly equipped with the right welding machine 13, the right welding machine 13 has a right welding tip 11, and the right welding tip 11 is installed on the right support 12 , the right welding nozzle 11 is located above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com