Rope socket rolling stopper of main ropes

A rope head cover and main rope technology, which can be used in transportation and packaging, elevators, etc., can solve the problems of accelerated wear and deterioration of main ropes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

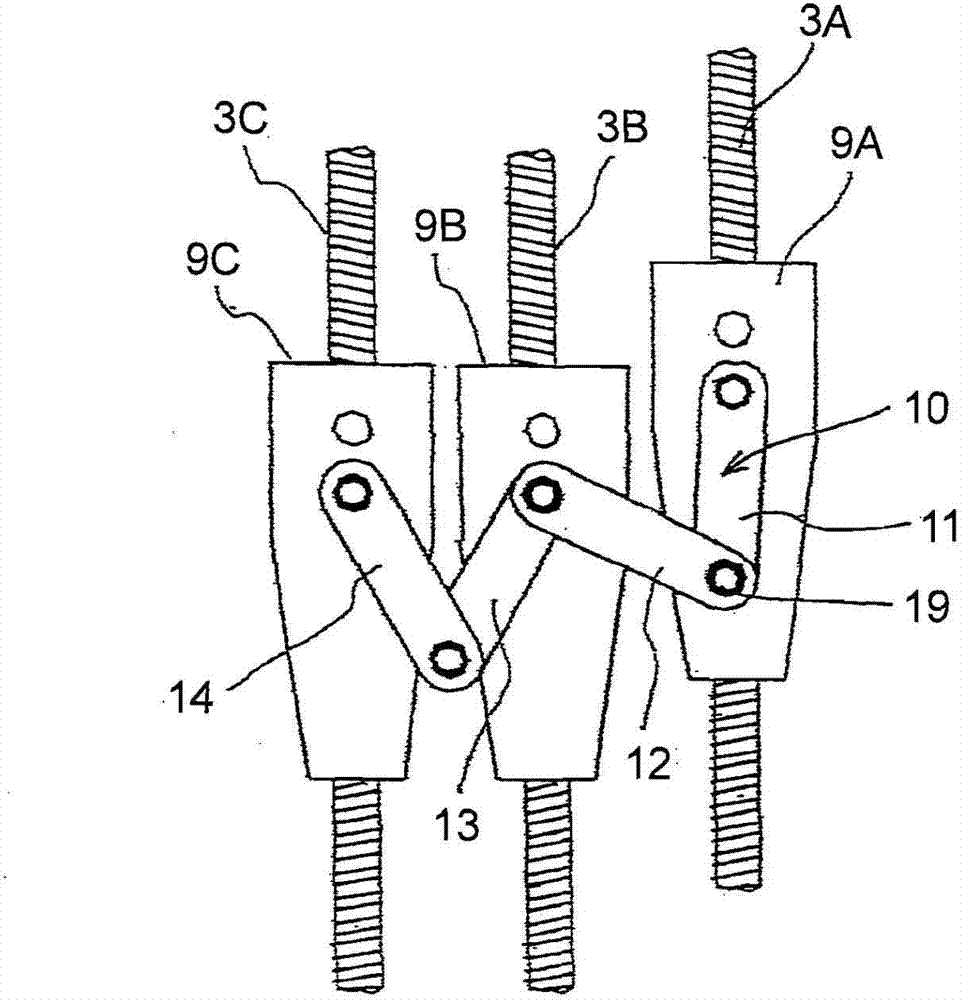

[0035] Hereinafter, an embodiment of the end cap rotation preventing device for a main rope according to the present invention will be described based on the drawings.

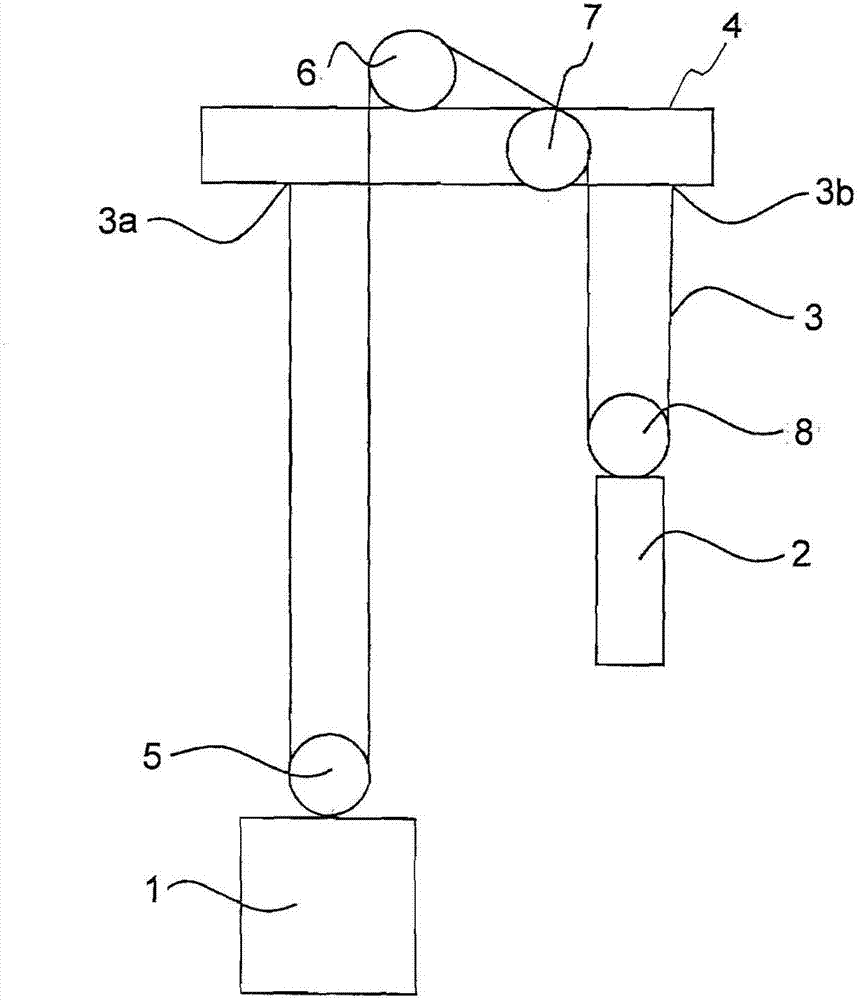

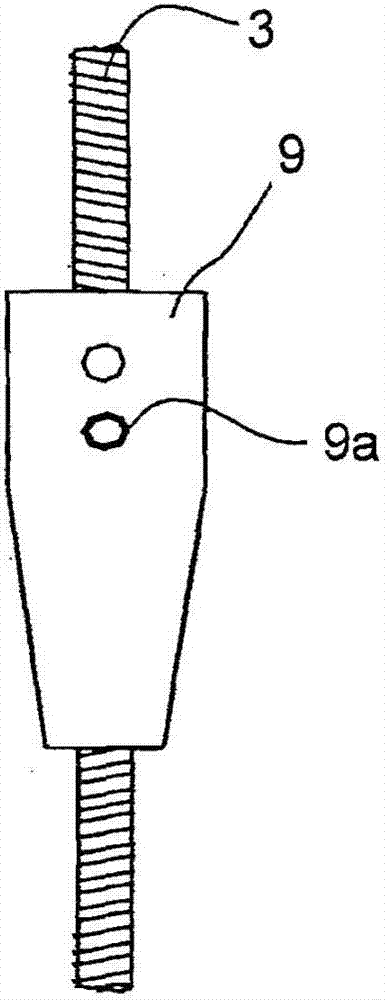

[0036] figure 1 It is a diagram showing a schematic configuration of an elevator to which the rope end loop preventing device for main ropes according to the present invention is applied. figure 2 yes means figure 1 Front view of the rope end provided with the elevator shown.

[0037] figure 1 Indicates an elevator with a general 2:1 roping ratio. as it should figure 1 As shown, the elevator includes a car 1 , a counterweight 2 , and main ropes 3 for suspending the car 1 and the counterweight 2 . One end 3a and the other end 3b of the main rope 3 are held by, for example, a hoisting machine load beam 4 provided in an equipment room disposed above the lifting path. The main rope 3 is wound around a car-side pulley 5 provided in the car 1 , a traction pulley 6 and a guide pulley 7 provided in the equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com