Method for continuously producing hydroxylammonium

A technology of hydroxylammonium and hydroxylammonium salts, which is applied in the field of continuous process preparation of hydroxylammonium, and can solve the problems of high cost, reduced selectivity of hydroxylammonium, complex equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

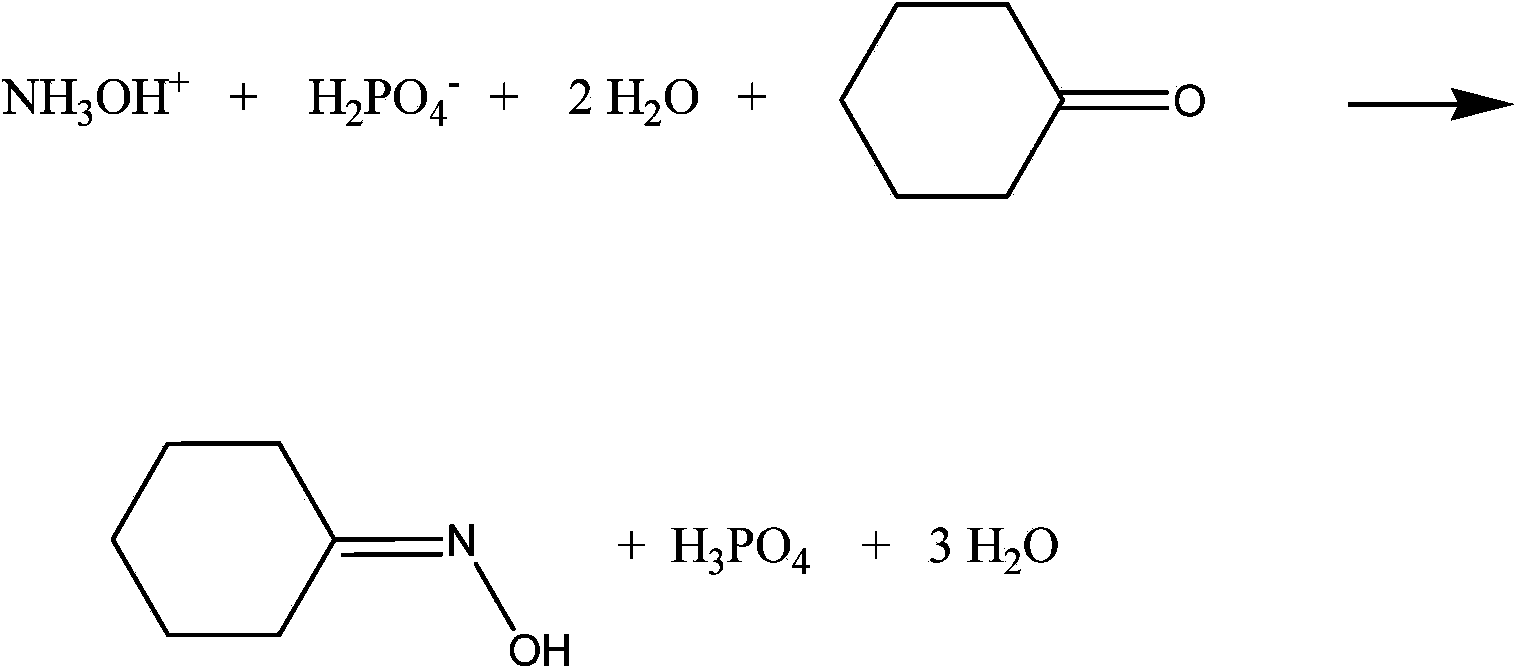

Method used

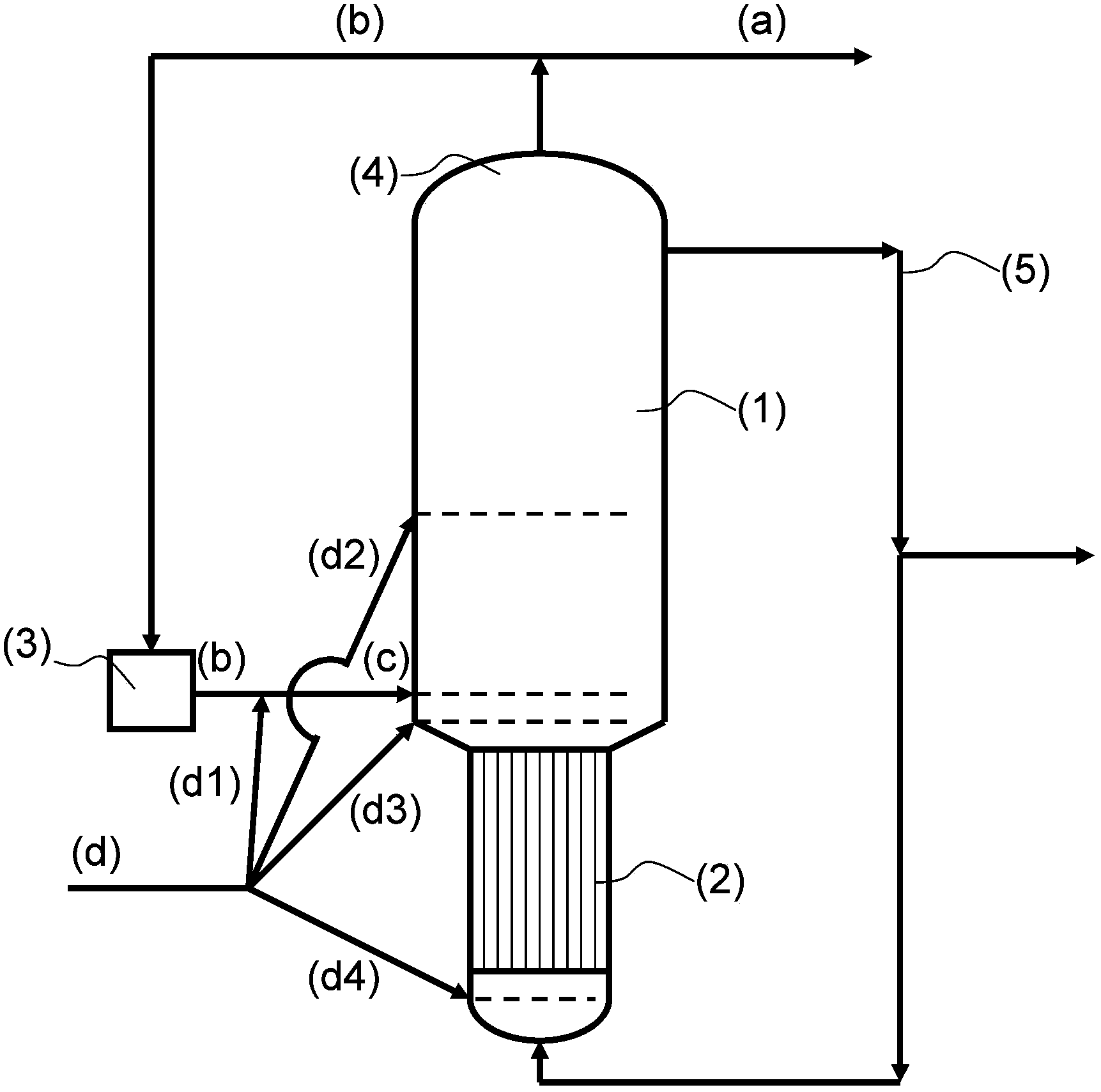

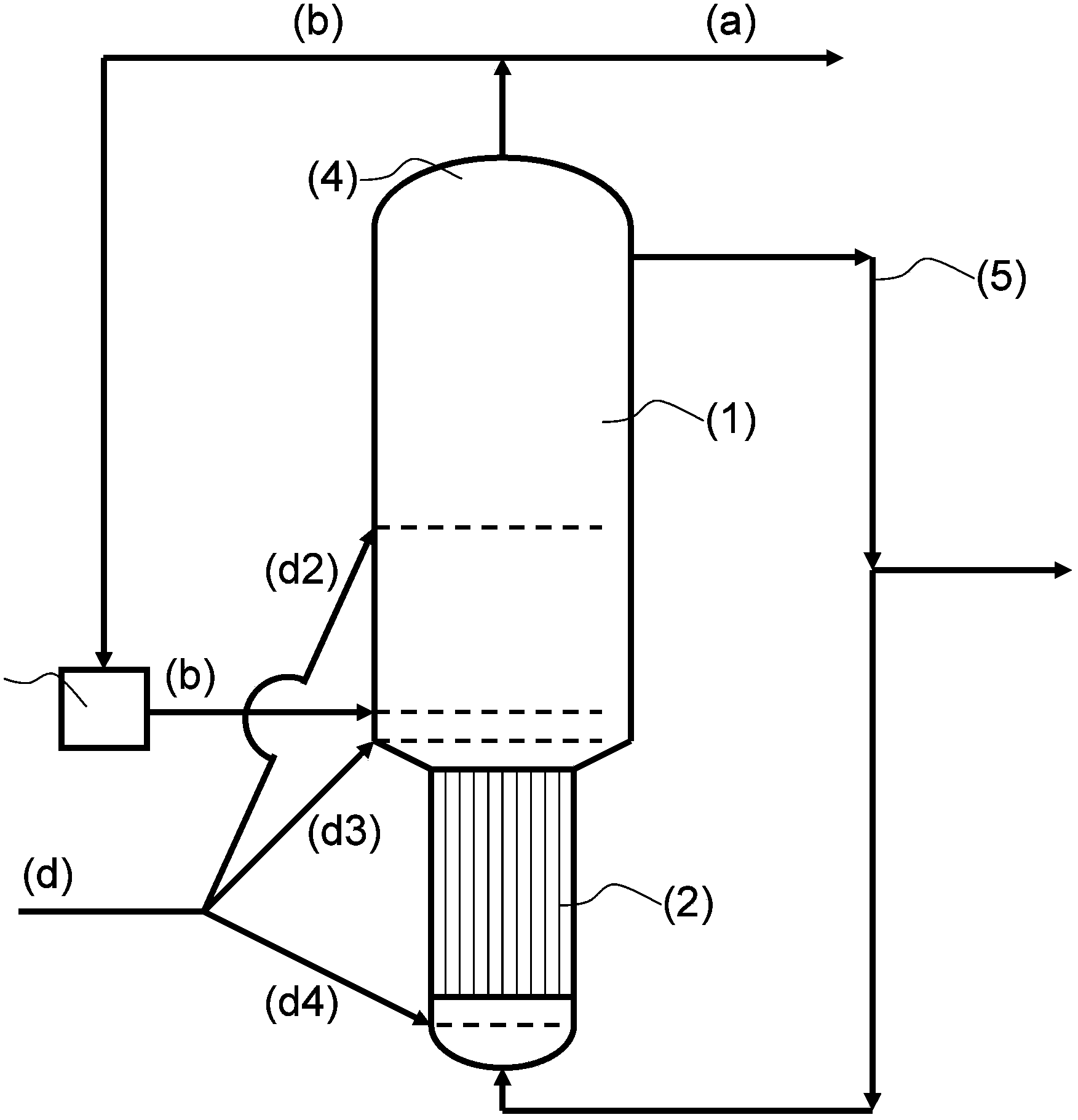

Image

Examples

Embodiment 1

[0087] The production of hydroxylammonium is carried out in the equipment, which adopts DSM technology. In the hydrogenation reactor, the by-product ammonia, N 2 O and N 2 .

[0088] The conditions of the nitrate hydrogenation reactor are:

[0089] Average temperature: 35-60°C

[0090] Reactor pressure: 2.0-3.0MPa.

[0091] Activator Type: GeO2

[0092] Activator / catalyst ratio: 3-7gr GeO 2 / kg catalyst

[0093] The compression ratio of the gas cycle compressor is in the range of 1.05 to 1.2.

[0094] Table 1 for catalyst type, d) fresh hydrogen component, dried a) off-gas component, off-gas:recycle gas ratio and hydroxylammonium selectivity.

[0095] The ratio of a) exhaust gas and b) circulating gas is maintained at 10:90-1:99.5; and the concentration of hydrogen in the purified gas is guaranteed to be greater than 30% by volume and less than 75% by volume, so that the selectivity of hydroxylammonium greater than 75% can be maintained .

[0096] Table 1

[0097]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com