Method for preparing alginic acid and alginates from fresh sargassum as raw material

A technology of sargassum and alginic acid, which is applied in the field of preparation of alginic acid and alginate, which can solve the problems of poor stability, easy deterioration, and decreased viscosity, and achieve the effects of avoiding gelatin degradation, improving quality, and reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

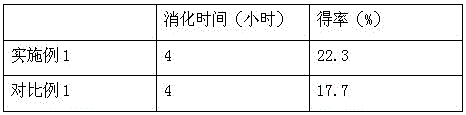

Embodiment 1

[0048] The method for preparing alginic acid with fresh sargassum as raw material, the method comprises the following steps:

[0049] (1) Cleaning: the raw material of fresh sargassum is washed with water to remove salt and impurities on the surface of fresh sargassum;

[0050] (2) Color fixation: chop up the washed fresh Sargassum algae, and add formaldehyde for "color fixation" treatment;

[0051] Cut the washed fresh sargassum into sections of about 6 cm, and soak the fresh sargassum with a formaldehyde solution of 0.9% at room temperature for 48 hours to fix the pigment protein. 4 times, release the soaking liquid after soaking;

[0052] (3) Digestion: The sargassum after the "fixation" treatment is digested with soda ash and transformed into liquid sodium alginate. During the digestion process, ultrasonic treatment is used;

[0053] Drain the algal bodies that have been treated with formaldehyde "fixation" and put them into a reaction kettle. Bond an ultrasonic transduc...

Embodiment 2

[0070] The method for preparing sodium alginate with fresh sargassum as raw material, the method comprises the following steps:

[0071] (1) Cleaning: the raw material of fresh sargassum is washed with water to remove salt and impurities on the surface of fresh sargassum;

[0072] (2) Color fixation: chop up the washed fresh Sargassum algae, and add formaldehyde for "color fixation" treatment;

[0073] Cut the cleaned fresh sargassum into 6cm sections, soak the fresh sargassum with a concentration of 0.9% formaldehyde solution at normal temperature for 48 hours, fix the pigment protein, and the volume of formaldehyde is the volume of fresh sargassum 4 times of that, release the soaking water after soaking;

[0074] (3) Digestion: Drain the algae treated with formaldehyde "color fixation" and put them into a reaction kettle, which has a built-in ultrasonic transducer vibrator, and the frequency range is controlled between 21-49 kHz; Soak in a sodium carbonate solution with a ...

Embodiment 3

[0081] The method for preparing sodium alginate with fresh sargassum as raw material, the method comprises the following steps:

[0082] (1) Cleaning: the raw material of fresh sargassum is washed with water to remove salt and impurities on the surface of fresh sargassum;

[0083] (2) Color fixation: chop up the washed fresh Sargassum algae, and add formaldehyde for "color fixation" treatment;

[0084]Cut the washed fresh sargassum into sections of about 6 cm, soak the fresh sargassum in a formaldehyde solution with a concentration of 0.8-1% at room temperature to fix the pigment protein, soak for 50 hours, and the volume of formaldehyde is the volume of fresh sargassum 4 times of that, release the soaking water after soaking;

[0085] (3) Digestion: Drain the algae treated with formaldehyde "fixation" and put them into a reactor. The outer wall of the reactor is bonded with an ultrasonic transducer vibrator, and the frequency range is controlled between 21 kHz and 49 kHz; S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com