Vacuum evaporation apparatus and method for replacing crucibles in vacuum evaporation apparatus

An evaporation device and evaporation technology, which can be used in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems of large-scale device and time-consuming, and achieve the simplification of replacement operation, prevention of condensation and adhesion, and reduction of Effects of Corrosion and Deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

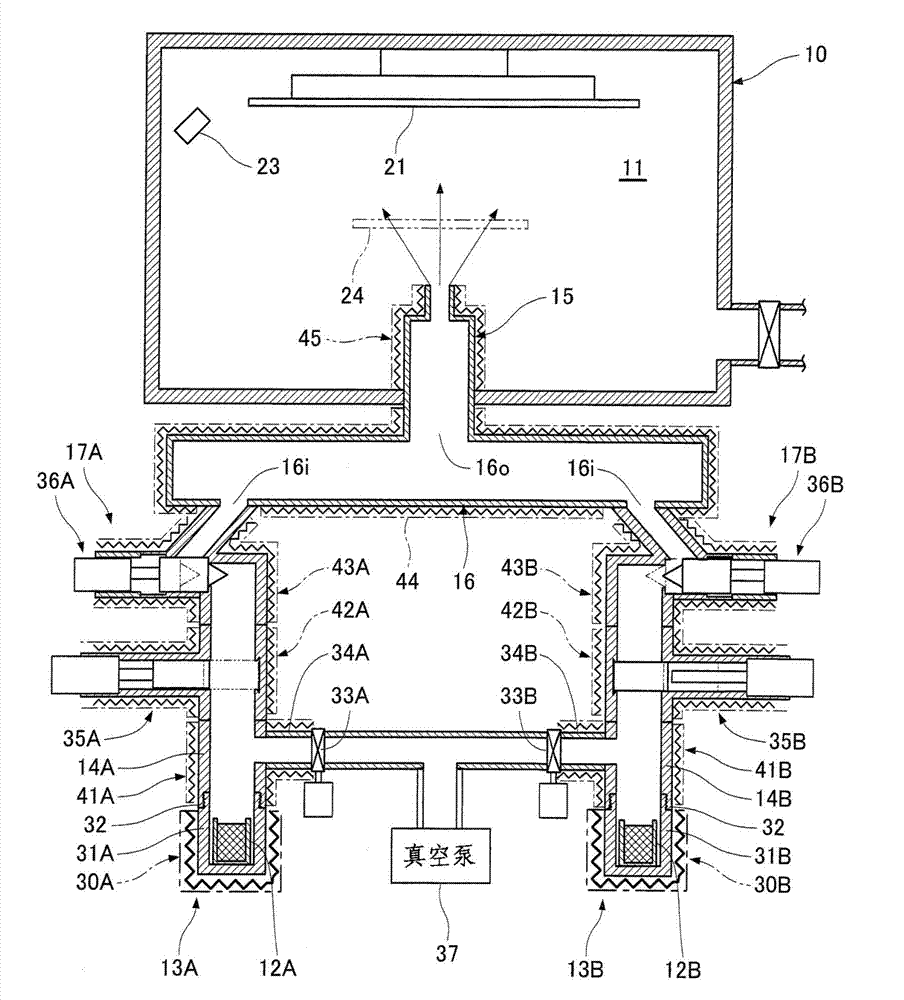

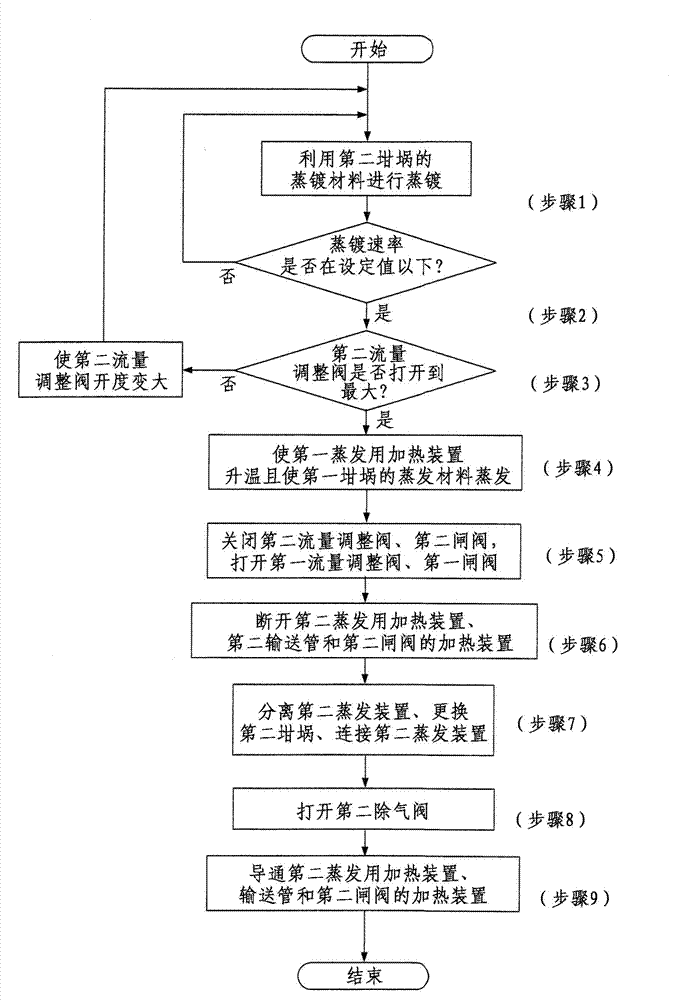

[0024] The following is based on Figure 1 to Figure 8 , an embodiment of the vacuum evaporation device and the crucible replacement method of the vacuum evaporation device of the present invention will be described.

[0025] (Structure of Vacuum Evaporation Device)

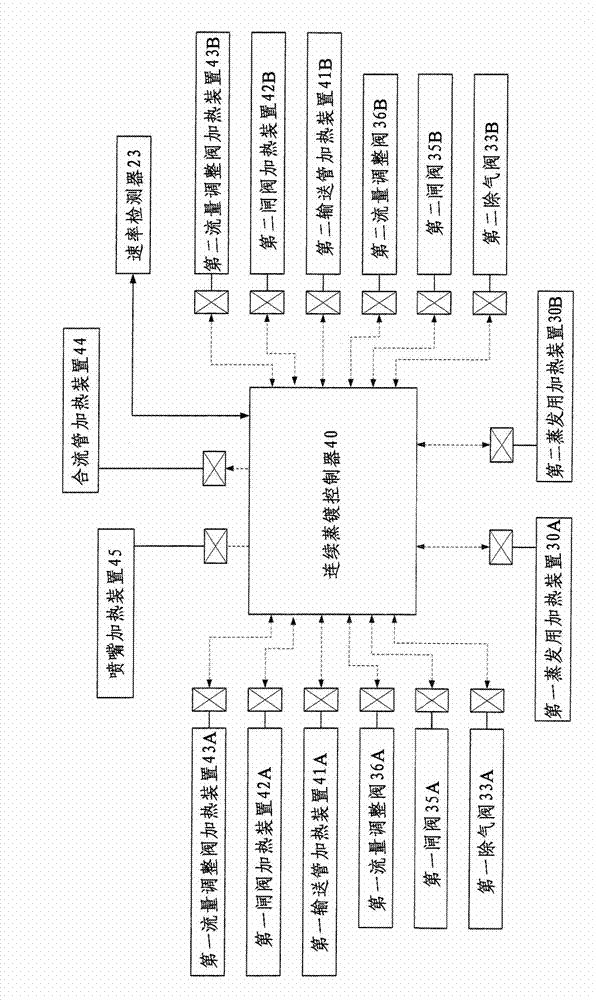

[0026] Such as figure 1 As shown, the above-mentioned vacuum evaporation device includes: a vacuum evaporation container 10 forming an evaporation chamber 11; first and second evaporation devices 13A and 13B having first and second crucibles 12A and 12B; first and second Delivery pipes 14A, 14B are respectively connected to the above-mentioned first and second evaporation devices 13A and 13B in a separable manner; a confluence pipe (manifold) 16 connects the vapor deposition materials from the first and second delivery pipes 14A and 14B sent to the vapor deposition nozzle 15; and the first and second continuous vapor deposition operation parts 17A and 17B are provided in the first and second delivery pipes 14A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com