Bridge cantilever box girder construction hanging basket pre-pressing loading device

A cantilever and bridge technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of slow loading time, high cost, high equipment requirements, etc., and achieve the effect of low cost, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

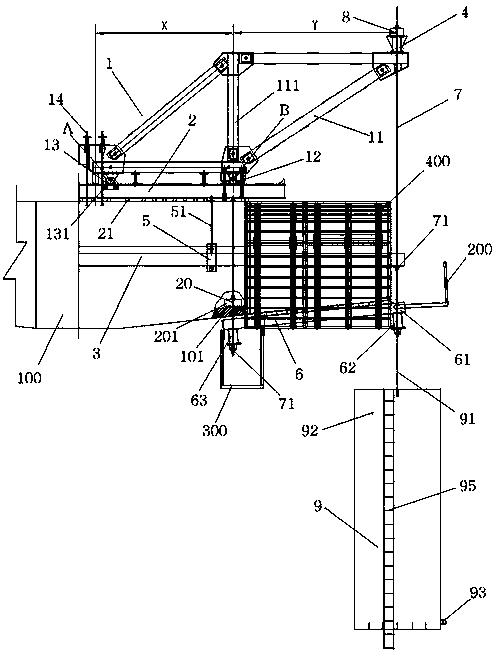

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

[0014] This embodiment simulates the downward pressure load of the bridge cantilever box girder to be poured to the bottom form support frame by hanging three water injection suspension buckets under the front lower crossbeam of the support frame of the bottom form. The weight M that must be satisfied after the water filling of the suspension bucket is determined by the following formula, and then the water injection height H of the suspension bucket is determined.

[0015] According to the principle of static moment balance, the following formula can be obtained:

[0016] 3MY=XN ie: M=XN / 3Y,

[0017] Thus it can be obtained: H=1.2×4(M-G) / πD2

[0018] In the formula, N: the weight of the cantilever box girder section of the bridge to be poured that needs to be preloaded (t),

[0019] X: the distance from the anchor center A to the front fulcrum B of the han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com