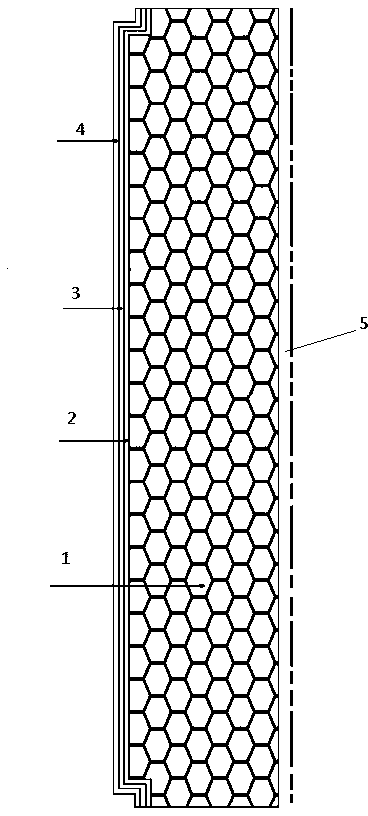

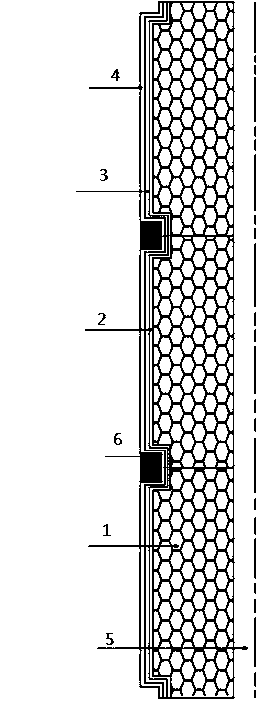

Heat-preserving decorative mold board for outer wall body and manufacturing method thereof

A technology of wall and thermal insulation mortar layer, which is applied in covering/lining, construction, building structure, etc., can solve the problems such as the large difference in the aging period of thermal insulation exterior walls, the decline of thermal insulation and decoration functions of external walls, and the cracks of thermal insulation external walls, etc. Achieve the effect of being suitable for industrialized continuous production, reducing the labor intensity of workers' work, and having a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

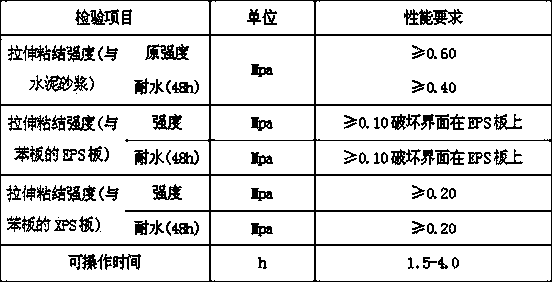

[0029] Embodiment 1: The described interface mortar layer comprises A component and B component, and the following raw material ratio of A component by weight: 340 kg of water, 30 kg of ethylene glycol, 2.5 kg of hydroxypropyl methylcellulose 75,000 viscosity, 1kg preservative BIT10W, 1kg defoamer 115, 2kg dispersant 4100, 0.5kg wetting agent 407, 1kg multifunctional additive AMP-95, 1kg construction aid 1052, 600kg interface Emulsion 403; the following raw material proportions by weight of component B: 350 kg of 42.5 black cement, 250 kg of quartz powder, 350 kg of 200 mesh heavy calcium carbonate, 3 kg of magnesium aluminum silicate mineral gel, the group A Points: B component = 1:2.

[0030] The thermal insulation mortar layer includes the following raw material proportions by weight: 350kg 42.5 black cement, 320kg 70 mesh quartz sand, 30kg 200 mesh heavy calcium carbonate, 30kg Class I fly ash, 1.5kg hydroxypropyl Base methyl cellulose 100,000 viscosity, 25kg rubber powde...

Embodiment 2

[0032]Embodiment 2: described interface mortar layer comprises A component and B component, and the following raw material ratio of A component by weight: 350 kg of water, 40 kg of ethylene glycol, 3 kg of hydroxypropyl methylcellulose 75,000 viscosity, 1.5kg preservative BIT10W, 1.5kg defoamer 115, 2.5kg dispersant 4100, 1kg wetting agent 407, 1.5kg multifunctional additive AMP-95, 1.5kg construction aid 1052, 600kg interface Emulsion 403; the following raw material proportions by weight of component B: 400kg 42.5 black cement, 300kg quartz powder, 400kg 200 mesh heavy calcium carbonate, 5kg magnesium aluminum silicate mineral gel, the first component : B component = 1:2.

[0033] The thermal insulation mortar layer includes the following raw material proportions by weight: 370kg 42.5 black cement, 350kg 85 mesh quartz sand, 50kg 200 mesh heavy calcium carbonate, 50kg Class I fly ash, 2.5kg hydroxypropyl Base methyl cellulose 100,000 viscosity, 30kg rubber powder 5044, 10kg ...

Embodiment 3

[0035] Embodiment 3: described interface mortar layer comprises A component and B component, and the following raw material ratio of A component by weight: 360 kg of water, 50 kg of ethylene glycol, 3.5 kg of hydroxypropyl methylcellulose 75,000 viscosity, 2kg preservative BIT10W, 2kg defoamer 115, 3kg dispersant 4100, 1kg wetting agent 407, 2kg multifunctional additive AMP-95, 2kg construction aid 1052, 600kg interface Emulsion 403; the following raw material proportions by weight of component B: 375 kg 42.5 black cement, 275 kg quartz powder, 375 kg 200 mesh heavy calcium carbonate, 4 kg magnesium aluminum silicate mineral gel, the first component : B component = 1:2.

[0036] The thermal insulation mortar layer includes the following raw material proportions by weight: 360 kg 42.5 black cement, 335 kg 85 mesh quartz sand, 40 kg 200 mesh heavy calcium carbonate, 40 kg I grade fly ash, 2 kg hydroxypropyl Base methyl cellulose 100,000 viscosity, 28kg rubber powder 5044, 8.5kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com