Top hanging type weighing platform of axle weight scale

A weighing platform and weighing platform technology, which is applied in the field of top-suspended axle load weighing platform, can solve the problems of high maintenance cost, high failure rate of weighing platform, and difficult maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

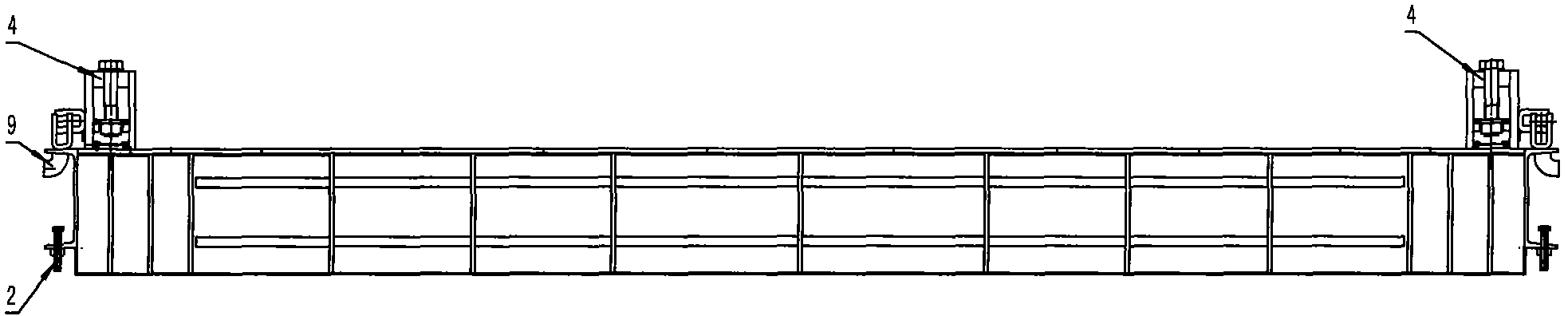

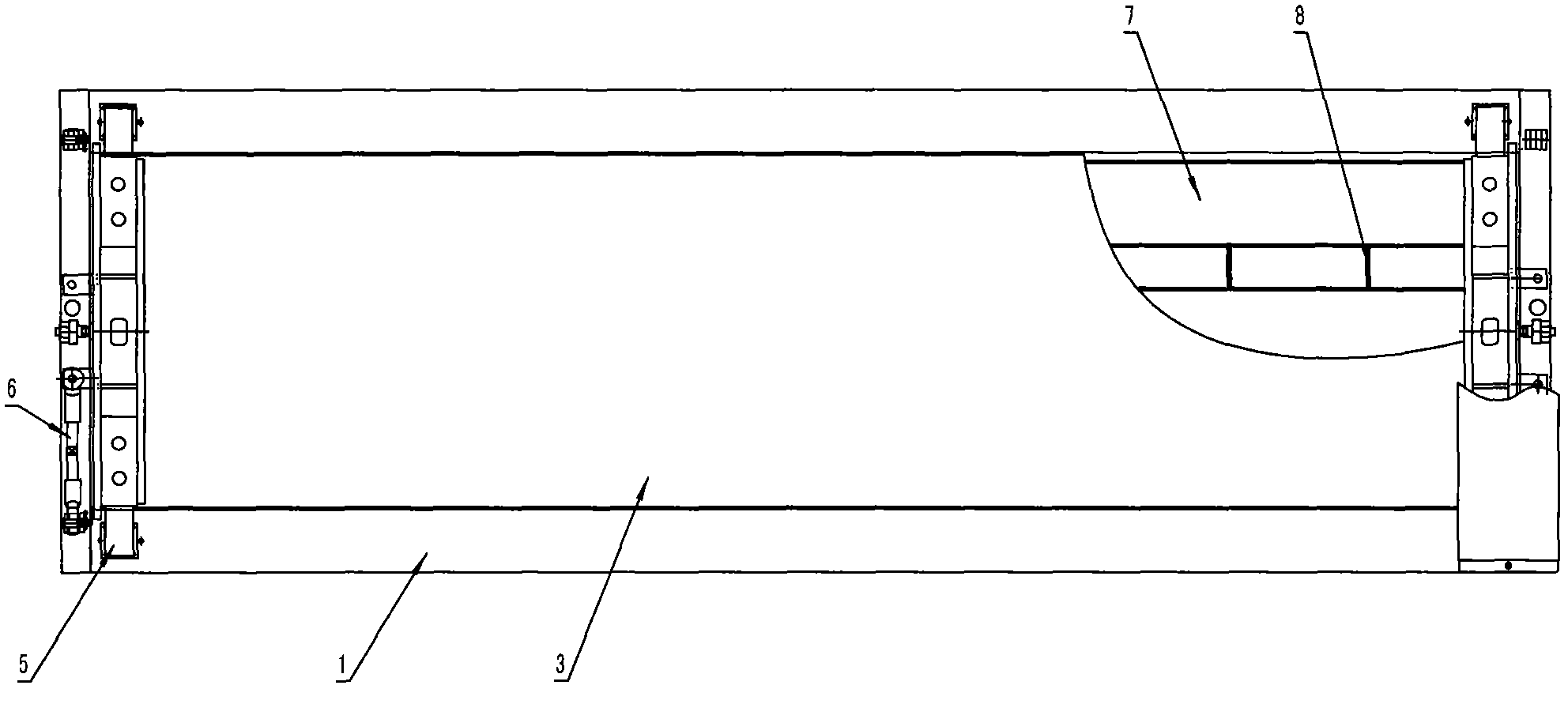

[0008] Taking the ZCU4A-30 type product produced by Shanxi Guoqiang Science and Technology Development Co., Ltd. as a specific example, the description is as follows: figure 1 Middle: The rectangular parallelepiped weighing platform frame (1) is 3732 mm long, 1232 mm wide, and 500 mm high; the axle load weighing platform (3) is 3300 mm long, 960 mm wide, and 540 mm high; the rectangular parallelepiped weighing platform frame (1) The inner frame of is slightly larger than the length, width and height of the axle load scale platform (3), allowing a gap of 10 millimeters on the periphery. The construction method is to pre-dug a cuboid pit in the weighing channel, adjust the upper surface of the cuboid weighing platform frame (1) to be flush with the road surface by adjusting the upper and lower adjustment screws (2) of the weighing platform frame, pour cement, and fix the rectangular parallelepiped weighing platform frame ( 1). Insert the load cells (5) into the suspension load-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com