A preparation method of copper alloy smart car shell that can be automatically replicated

A technology of copper alloy and car, which is applied in the field of preparation of the shell of smart cars, can solve the problems of not being able to automatically reproduce the shape, and achieve the effects of universality, simple preparation process, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] As introduced in the background technology, the shell of the current car (including the hood, the door, the tailgate, etc.) is molded from sheet metal. After the vehicle is rear-ended or collided, it will be deformed and cannot be automatically reshaped. . Therefore, the present invention proposes a kind of preparation method of the copper alloy smart car shell that can automatically reshape, comprising the following steps:

[0027] The first step is to use copper alloy plates to replace the plates used in the current shell;

[0028] The second step is to use the copper alloy plate to process the shell according to the current equipment tooling process;

[0029] The third step is to put the shell processed in the second step into the heating equipment, heat it to 840°C-845°C, and keep it warm for 15-19 minutes;

[0030] The fourth step is to take out the shell that has been heated and kept warm in the third step, put it into boiling water, and keep it for 35-40 minute...

Embodiment 1

[0037] Embodiment 1: a kind of preparation method of the copper alloy smart car shell that can automatically reshape, comprises the following steps:

[0038] The first step is to put the cylindrical copper alloy mesh into the heating equipment, heat it to 840°C, and keep it warm for 15 minutes;

[0039] The second step is to take out the shell that has been heated and kept warm in the second step, put it in boiling water, and keep it for 35 minutes;

[0040] Step 3 Remove the shell from the boiling water and place it in liquid nitrogen to cool for 5 minutes.

[0041] The fourth step is polishing or coloring.

[0042] The phase transition point As of the copper alloy in the first step is ≤-41°C.

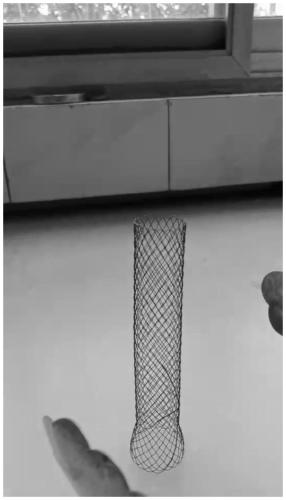

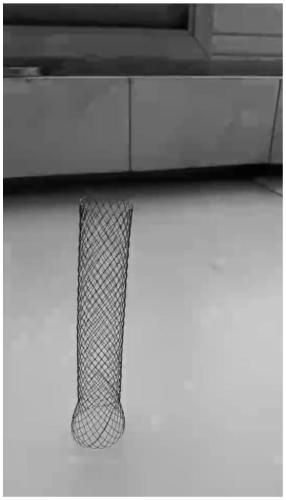

[0043] Performance test: the cylindrical copper alloy net prepared in embodiment 1 (such as figure 1 ), hold it with tweezers for 2~3s until it is completely deformed (such as figure 2 ), release the tweezers, and the cylindrical copper alloy mesh quickly (1~2s) returns to its or...

Embodiment 2

[0044] Embodiment 2: a kind of preparation method of the copper alloy smart car shell that can automatically reshape, comprises the following steps:

[0045] The first step is to use copper alloy plates to replace the plates used in the current shell;

[0046] The second step is to use the copper alloy plate to process the shell according to the current equipment tooling process;

[0047] The third step is to put the shell processed in the second step into the heating equipment, heat it to 845°C, and keep it warm for 19 minutes;

[0048] The fourth step is to take out the shell that has been heated and kept warm in the third step, put it in boiling water, and keep it for 40 minutes;

[0049] Step 5 Remove the shell from the boiling water and cool in liquid nitrogen for 10 minutes.

[0050] The sixth step is polishing or coloring.

[0051] The phase transition point As of the copper alloy in the first step is ≤-42°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com