Oil charging device oil permeating point positioning detector and using method thereof

An oil-filled equipment and point positioning technology, which can solve the problems of time-consuming, inaccurate, and poor versatility, and achieve Simple and convenient operation, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

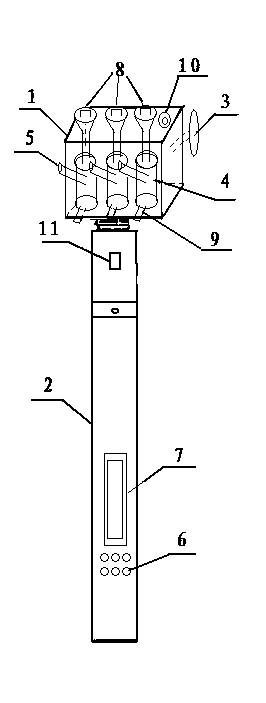

[0026] Such as figure 1 As shown, an oil-filled equipment oil seepage point location detector includes an insulating rod body 2 and an insulating box body 1 placed on the top of the insulating rod body 2; a camera 10 and a detachably connected motorized The insulating brush head 3 and the insulating box body 1 are provided with three automatic sprayers 4, which are respectively used to contain the penetrating agent, the white developer and the cleaning agent. The nozzle 5 of each automatic sprayer 4 passes through the side plate of the insulating box body 1 away from the electric insulating brush head 3; the insulating rod body 2 has a built-in motor 11, and the lower end of the insulating rod body 2 is provided with different gears for controlling the electric insulating brush The rotation or reciprocating movement of the head 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com