High-power LED (light-emitting diode) chip packaging quality detecting method

A quality inspection method and LED chip technology, which are applied in the direction of single semiconductor device testing, etc., can solve the problems that are not suitable for online batch inspection of high-power LED packaging quality, and are not suitable for high-power LED chip packaging quality inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described below in conjunction with accompanying drawing.

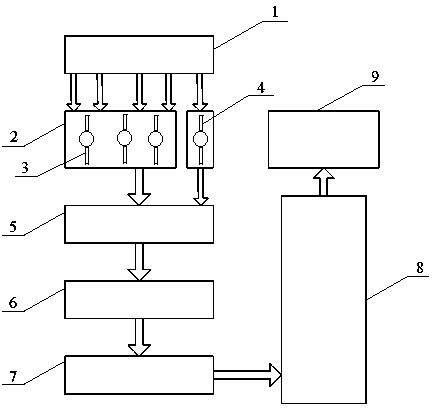

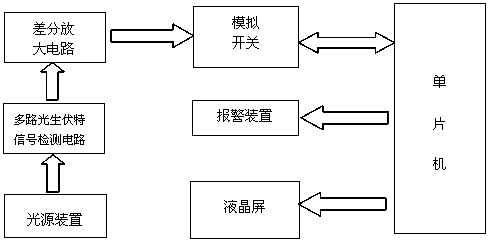

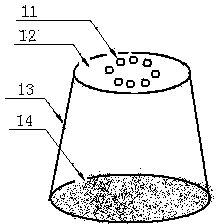

[0020] High-power LED chip packaging quality inspection method, the principle block diagram is as follows figure 1 Shown: During the LED chip packaging process, the uniform light field generated by the light source device (1) is used to vertically irradiate the light-receiving surfaces of the high-power LED (3) to be tested and the standard LED (4) on the LED bracket (2) ; Secondly, use the pin fixture (5) to introduce the photo-generated current signal generated on the PN of the LED into the multi-channel signal sampling comparison circuit (6); in the multi-channel signal sampling comparison circuit (6), firstly, the two constant voltage sources The sampling circuit composed of UI (10) and U2 (11), LED and sampling resistor R (12) in series converts the photo-generated current signal into a photo-generated voltage signal, and then inputs the photo-generated voltage signal generated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com