Intelligent control method for scale-prevention and scale-removal of ultrasonic scale-prevention and scale-removal device

An anti-scaling and descaling, intelligent control technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of increasing energy consumption, low degree of automation, affecting the effect of anti-scaling and descaling, and achieve system stability and safety. High stability and the effect of reducing errors

Active Publication Date: 2013-10-23

谷俊峰

View PDF6 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Ultrasonic anti-scaling and descaling technology is a new anti-scaling and descaling technology. It has the characteristics of high performance, high safety, online anti-scaling and descaling, green environmental protection and low cost. It has been widely used in the indus...

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0045] The values of ΔTk and Qk are 2%, and others are the same as in Example 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

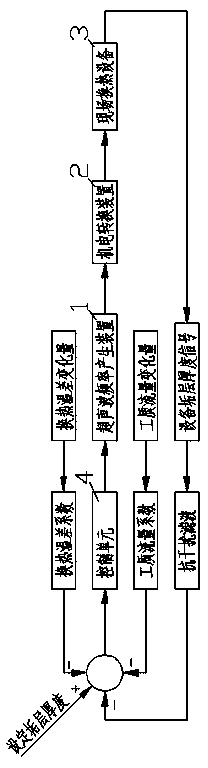

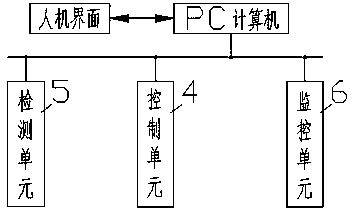

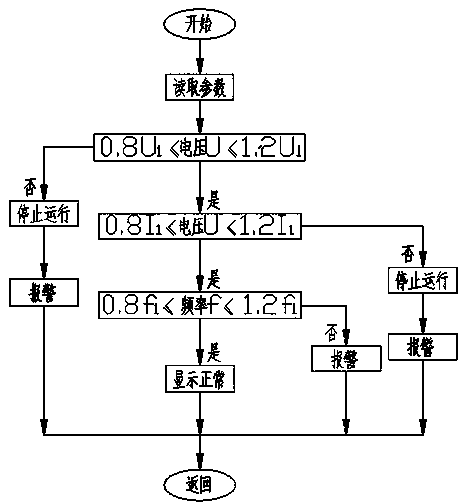

An intelligent control method for scale-prevention and scale-removal of an ultrasonic scale-prevention and scale-removal device can make the device be in the best operation state, reduces energy consumption of a whole scale-prevention and scale-removal system, prolongs the service life of the device, and improves safety stability. The intelligent control method comprises the steps that the ultrasonic scale-prevention and scale-removal device is composed of an ultrasonic frequency generating device and an electro-mechanical transformation device, a microcomputer control system is composed of a detecting unit, a control unit and a monitoring unit, the electro-mechanical transformation device is perpendicularly arranged on a tube plate of a site heat exchange device, the detecting unit detects parameters of the site heat exchange device in real time, the control unit controls output power of the whole scale-prevention and scale-removal system according to the parameters of the site heat exchange device and control procedures, the monitoring unit monitors output voltage U, an output current I and driving frequency f of the ultrasonic scale-prevention and scale-removal device, the operation state of the ultrasonic scale-prevention and scale-removal device is judged, normal operation or breakdown/halt is displayed, and an alarm signal is given when breakdown occurs.

Description

technical field [0001] The invention relates to an intelligent control method for the anti-scaling and descaling of ultrasonic anti-scaling and descaling equipment, in particular to the intelligent control method for the anti-scaling and descaling of the ultrasonic anti-scaling and descaling equipment acting on heat exchange equipment. Background technique [0002] Ultrasonic anti-scaling and descaling technology is a new anti-scaling and descaling technology. It has the characteristics of high performance, high safety, online anti-scaling and descaling, green environmental protection and low cost. It has been widely used in the industrial field and has achieved However, the current ultrasonic descaling equipment has a low degree of automation and cannot keep the anti-scaling and descaling system in the best operating state, which affects the anti-scaling and descaling effect and increases energy consumption. Contents of the invention [0003] The technical problem to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): G05B19/042F28G7/00

Inventor 谷俊峰诸兰伟

Owner 谷俊峰

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap