Carbon-brush seat

A technology of carbon brush seat and carbon brush, which is applied in the direction of current collectors, electrical components, rotating current collectors, etc., and can solve problems such as uneven wear parts, unfavorable smooth movement of carbon brushes, and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

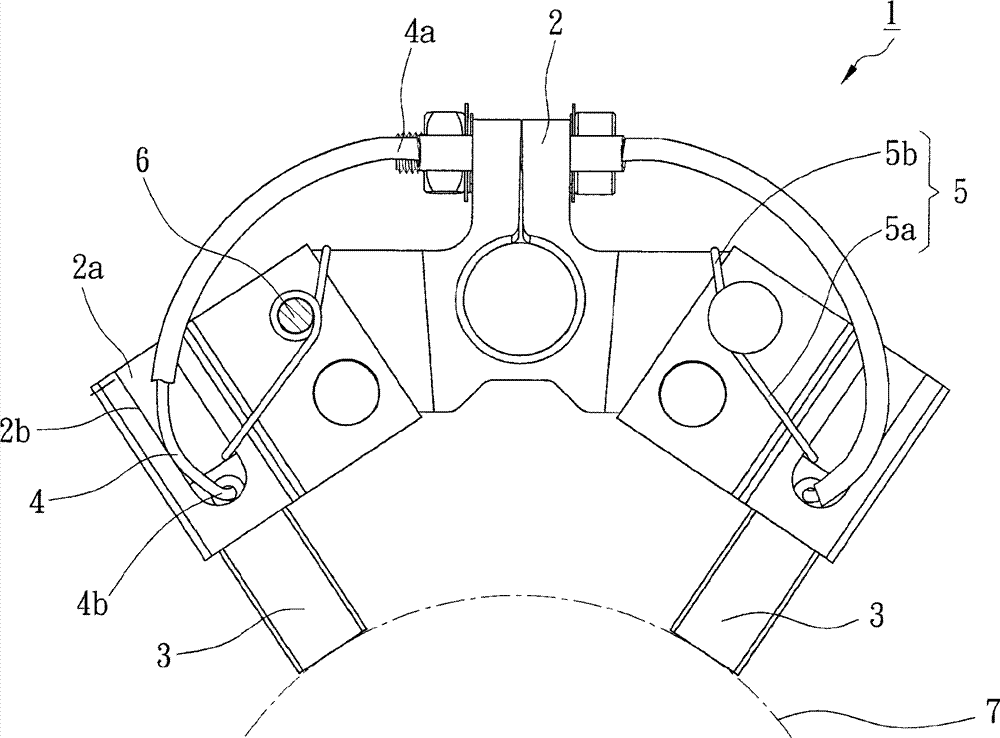

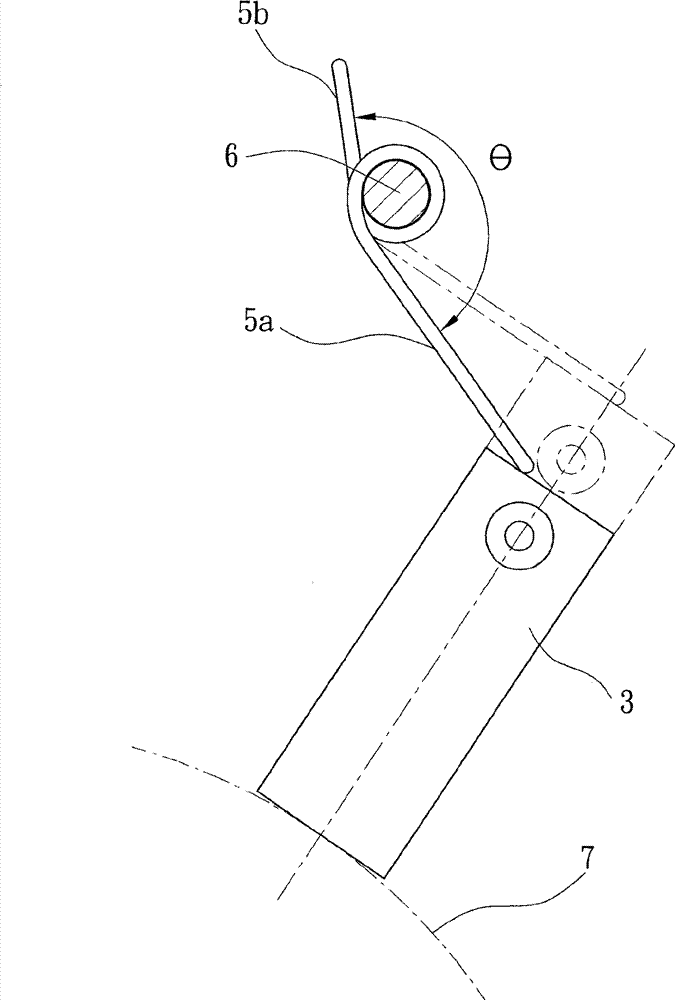

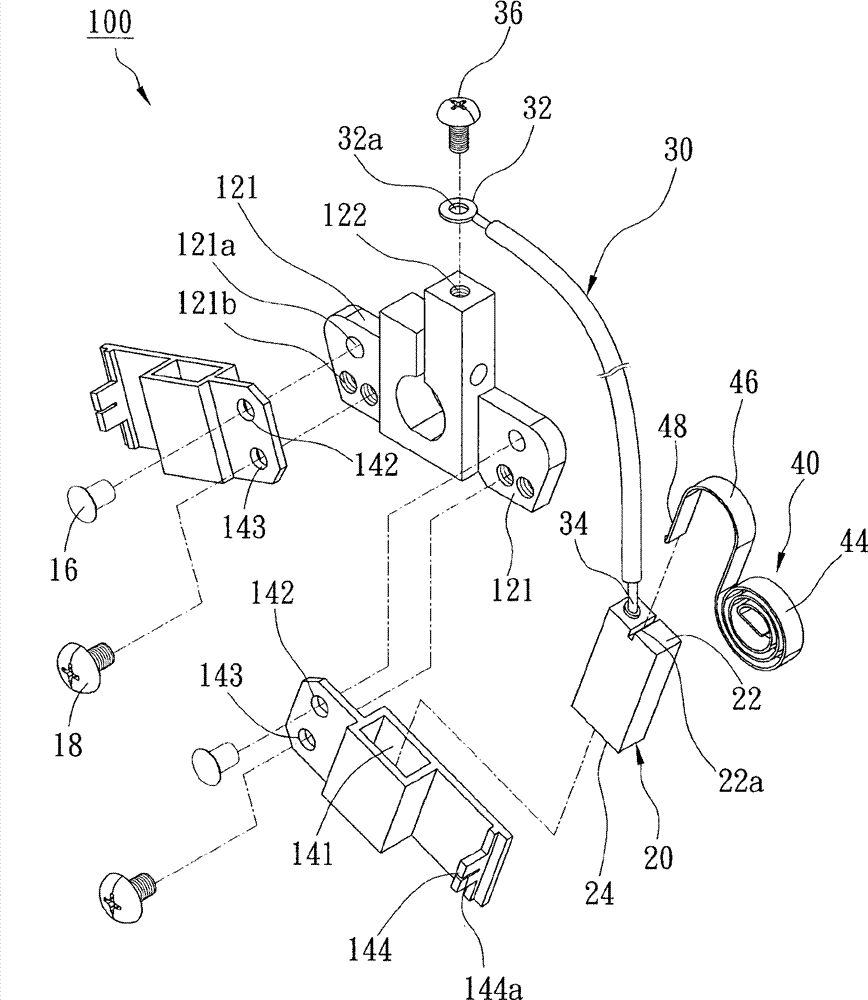

[0046] The carbon brush holder provided by the present invention includes a support frame, a carbon brush and a coil spring. Wherein, at least one side of the support frame has a carbon brush accommodating groove penetrating through the top and bottom surfaces; the carbon brush is movably arranged in the carbon brush accommodating groove, and has a top end and a bottom end; the coil spring has a curved portion and An extension portion, wherein the curled portion has a crimping center fixed on the support frame, the crimping center is located on one side of the carbon brush accommodating groove, and is located in the range of the parallel extension direction of the top surface and the bottom surface; The extension portion has a pressing end spanning the top surface, and the pressing end abuts against the top end of the carbon brush.

[0047] In one embodiment, the support frame has a protrusion adjacent to the carbon brush receiving groove, and the curled portion of the coil sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com