Graphite heater

A technology of graphite heater and graphite heating, applied in heating elements, ohmic resistance heating, ohmic resistance heating parts, etc., can solve problems such as blurred pictures and achieve the effect of meeting heating needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

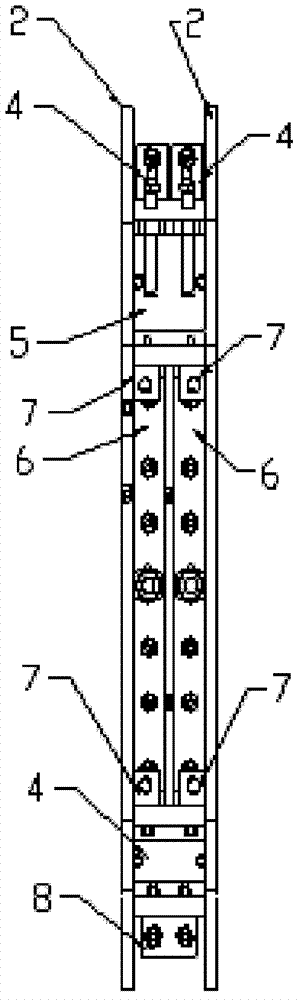

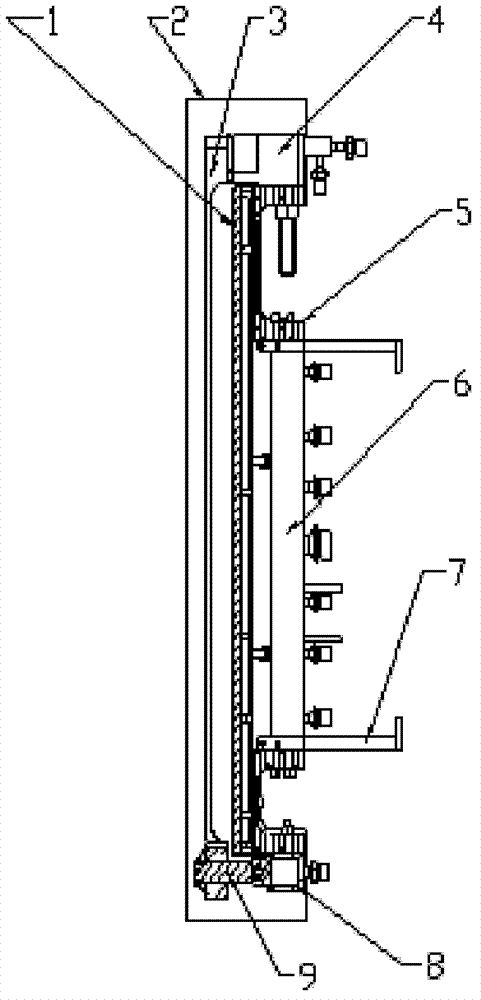

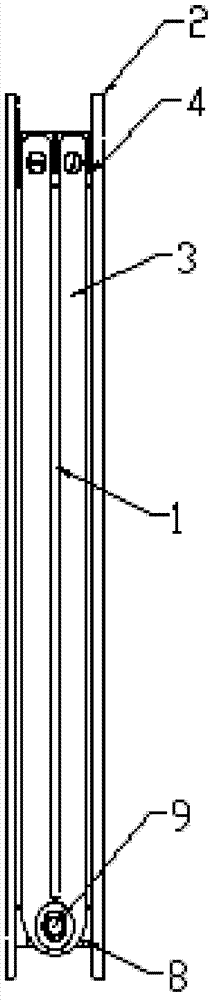

[0023] A kind of graphite heater, its overall structure is as figure 1 , figure 2 , image 3 As shown, it includes main reflector 1, side reflector 2, graphite heating element 3, power confluence mechanism 4, insulation mechanism 5, water collector 6, installation support mechanism 7, cooling water tank 8 and compensation end 9; the main reflector 1. The side reflector 2, the power converging mechanism 4 and the cooling water tank 8 are all hollow water cooling structures, and all have water inlets and water outlets. The main reflector 1 and the side reflector 2 are flat-plate hollow water cooling structures, and their size matches the graphite heating element 3. They are both made of polished aluminum plates. Improve the reflectivity of the reflective surface and improve the heating efficiency of graphite heating 3; in order to further improve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com