Disposable dental interproximal slice saw

A one-time, adjacent surface technology, applied in the direction of dental saws, etc., can solve the problems of inconvenient operation, irregular slice cutting, unsafe and other problems, and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

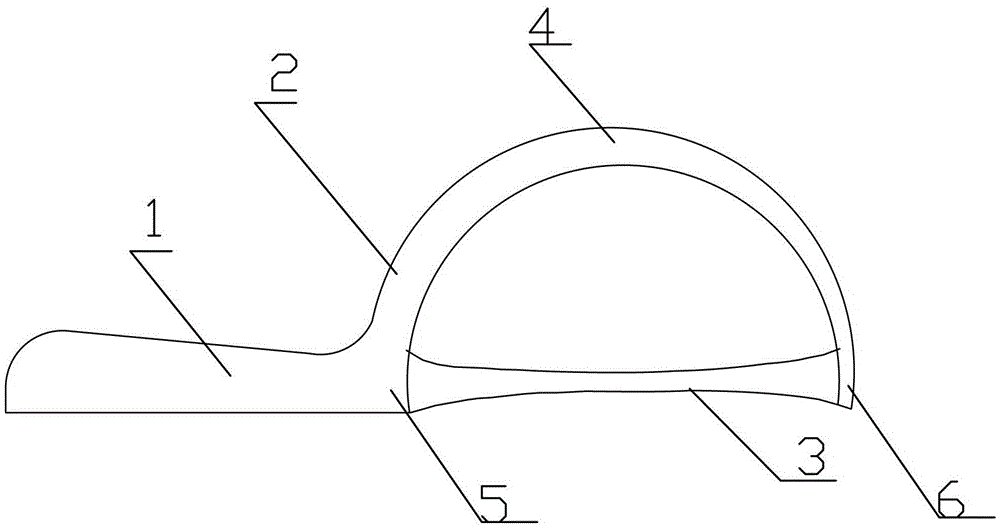

[0022] figure 1 It is the first embodiment of the present invention. Such as figure 1 As shown, the saw handle 1 is fixedly connected to the left end 5 of the saw frame 2, the saw handle 1 and the arc saw bow 2 are on the same plane, and the left end 5 of the saw frame is wider than the right end of the saw frame 3 width. The width of the left end 5 of the saw frame is 5 mm, and the width of the right end 6 of the saw frame is 3.5 mm.

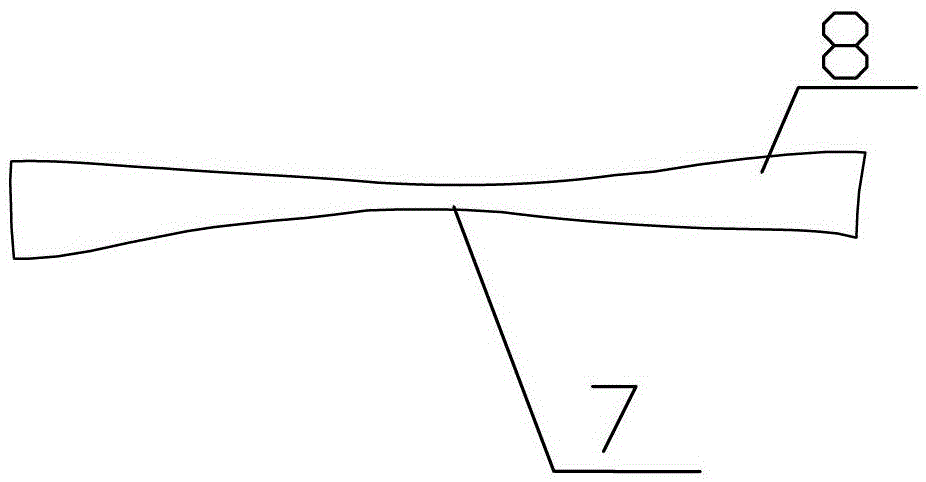

[0023] The adjacent sand bar 3 has a flat structure, and the adjacent sand bar 3 includes both ends 8 of the sand bar and a middle part 7 of the sand bar. The width of the two ends 8 of the sand bar is greater than the width of the middle part 7 of the sand bar. The width of the middle part 7 of the sand bar is 2 mm, and the width of both ends 8 of the sand bar is 5 mm. The saw handle 1 and the curved saw frame 2 are made of plastic. The adjacent sand bar 3 is fixed on the left end 5 of the saw frame and the right end 6 of the saw frame by...

Embodiment 2

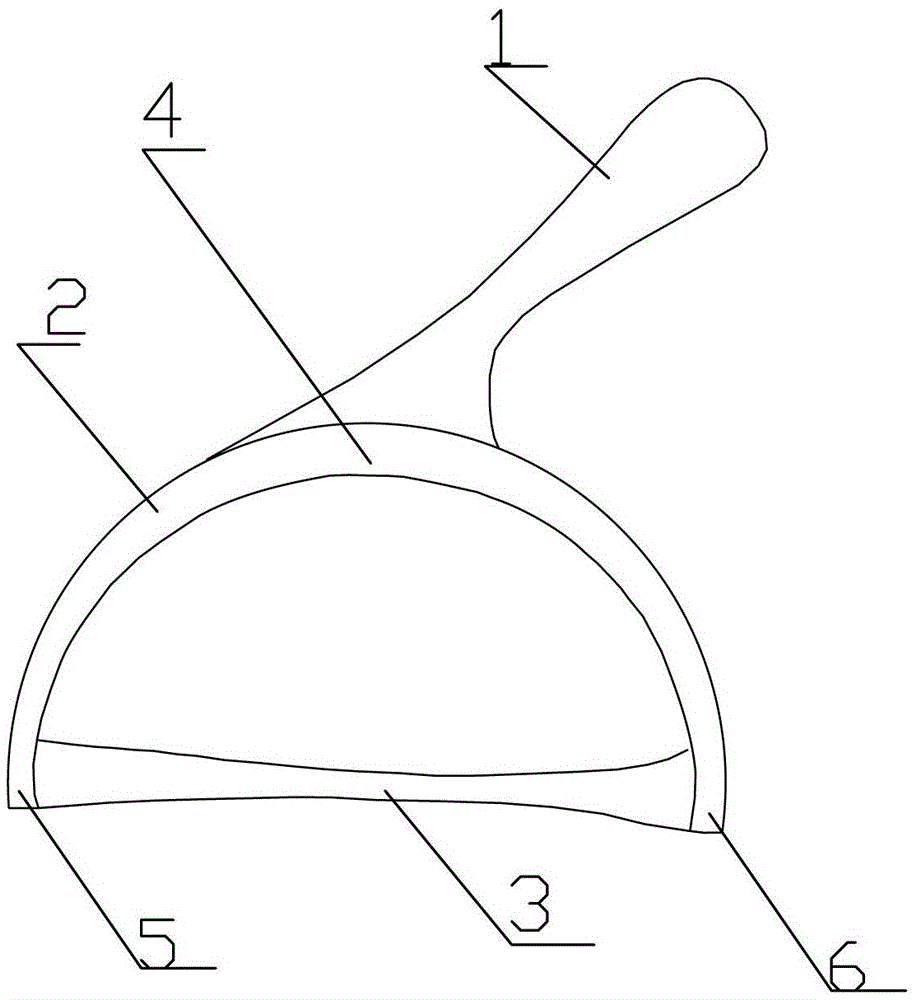

[0026] figure 2 It is the second embodiment of the present invention. Such as figure 2 As shown, the saw handle 1 is fixedly connected to the bow 4 of the arc saw frame 2, the saw handle 1 is perpendicular to the plane where the arc saw frame 2 is located, and the width of the left end 5 of the saw frame is the same as the width of the right end 6 of the saw frame , the width of the saw bow 4 is greater than the width of the left end 5 of the saw frame. The width of the saw bow 4 is 5 mm, the width of the left end 5 of the saw frame and the width of the right end 6 of the saw frame are both 3.5 mm.

[0027] The adjacent sand bar 3 has a flat structure, and the adjacent sand bar 3 includes both ends 8 of the sand bar and a middle part 7 of the sand bar. The width of the two ends 8 of the sand bar is greater than the width of the middle part 7 of the sand bar. The width of the middle part 7 of the sand bar is 2 mm, and the width of both ends 8 of the sand bar is 5 mm. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com