Welding device and welding method for outlet ends of one-way valves of capillary components

A technology of welding device and one-way valve, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high labor intensity, low production efficiency, and non-continuous operation of employees, so as to reduce labor intensity, reduce fatigue, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

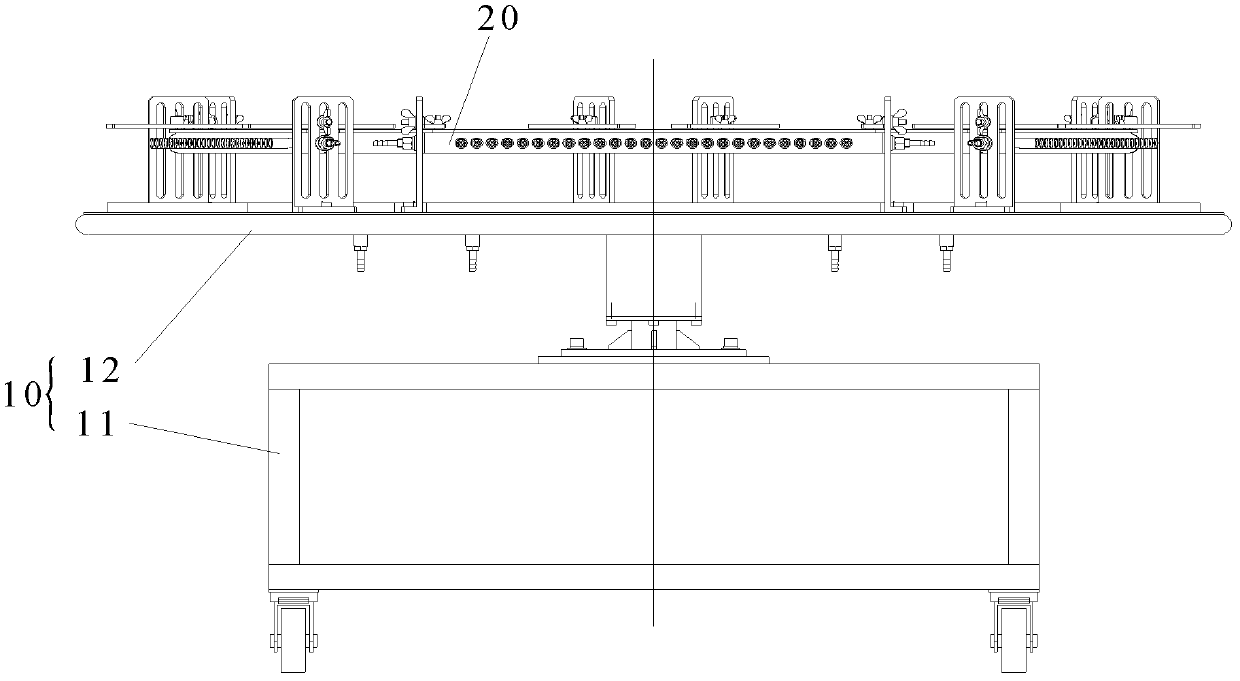

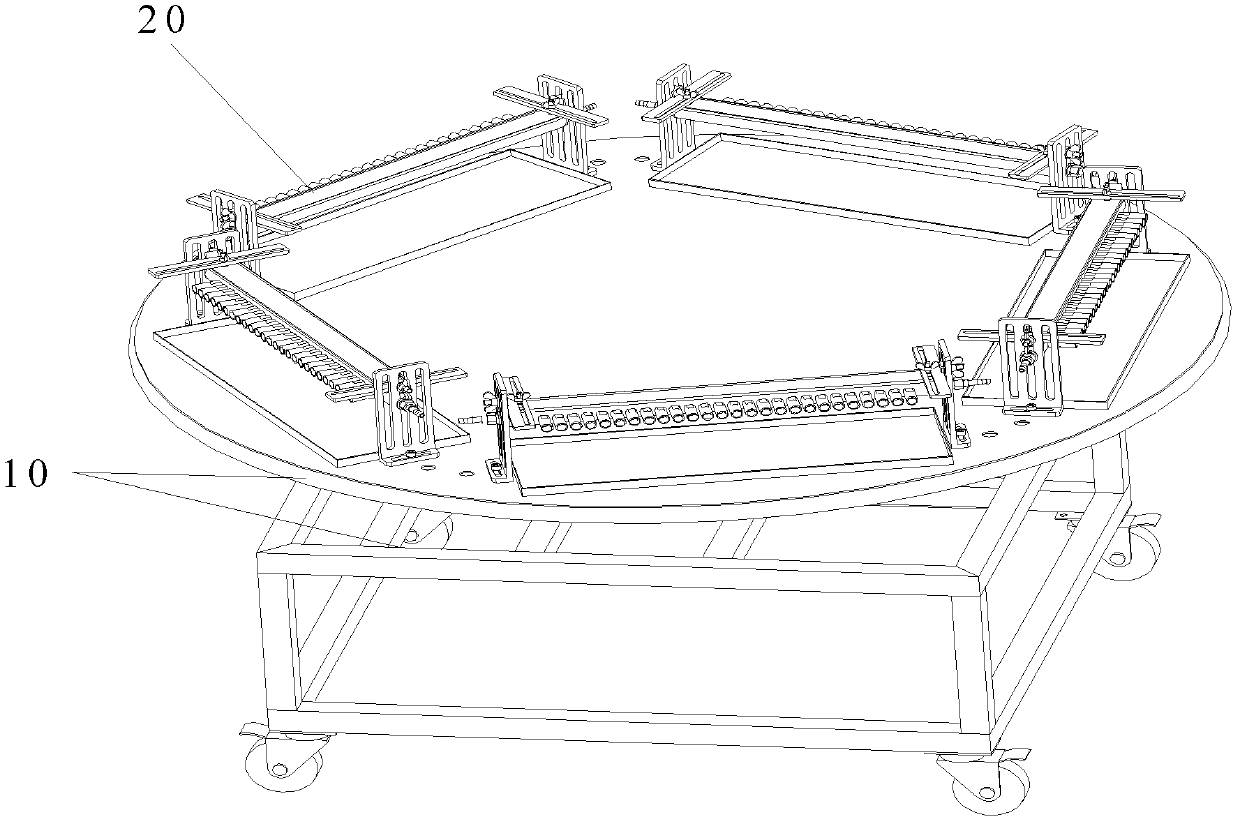

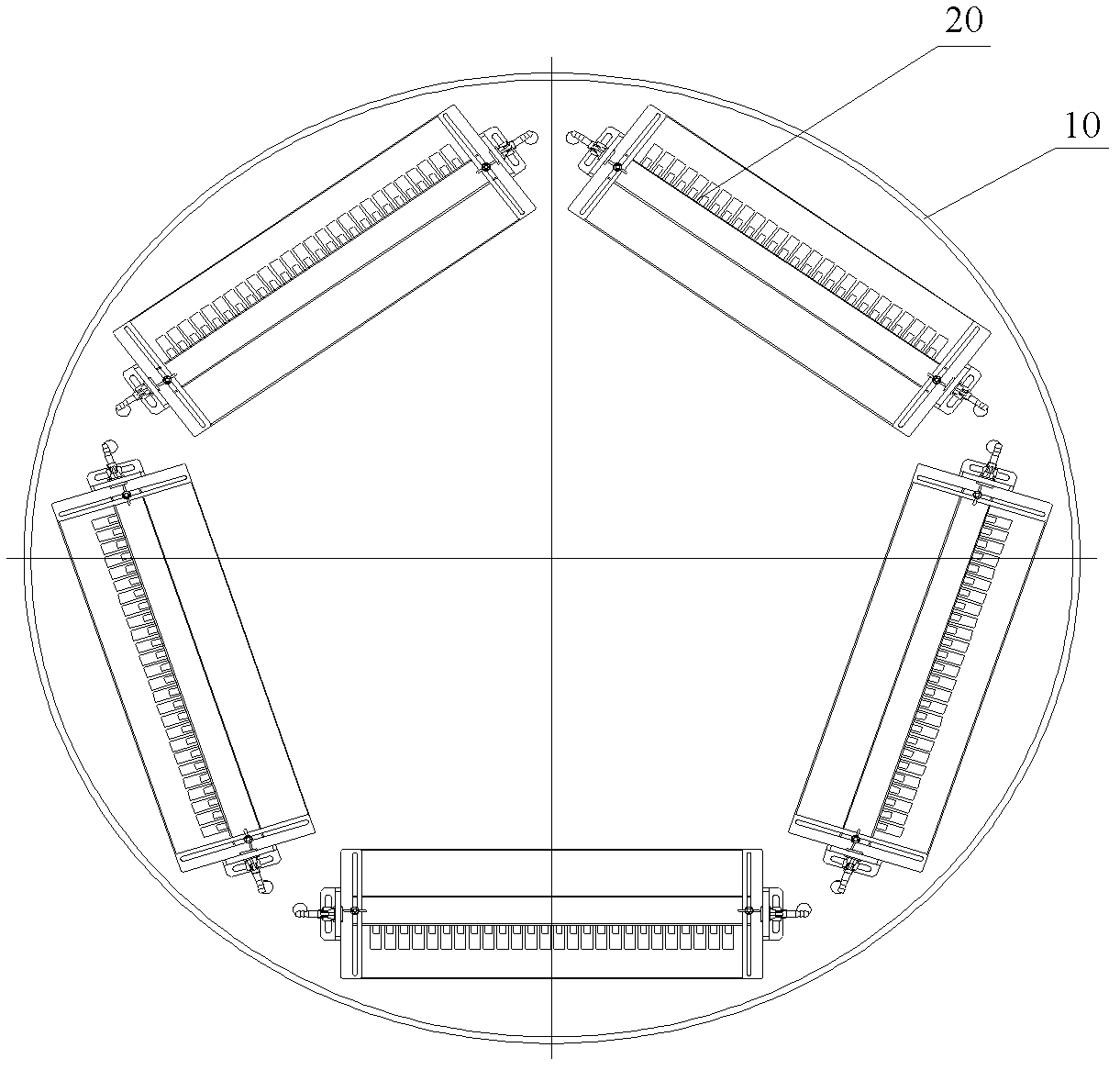

[0030] see figure 1 and figure 2 , according to the welding device of the outlet end of the one-way valve of a kind of capillary assembly of the present invention, comprise: comprise main nitrogen filling turntable mechanism 10 and nitrogen distribution positioning mechanism 20, main nitrogen filling turntable mechanism 10 comprises frame 11 and is rotatably arranged The rotating disk 12 on the frame 11; the nitrogen distribution positioning mechanism 20 includes a plurality of positioning brackets 22 arranged on the rotating disk 12 and the nitrogen distribution pipe 21 arranged on the positioning support 22; the nitrogen distribution pipe 21 is provided with a plurality of filling Nitrogen mouth 211. The main nitrogen filling turntable mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com