Left-right swing device for yarn guide roll

A technology of swinging left and right, yarn guide rollers, used in other manufacturing equipment/tools, textiles and papermaking, rewinding machines, etc., can solve the problem of uneven arrangement of warp yarns, and achieve the effect of uniform yarn tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

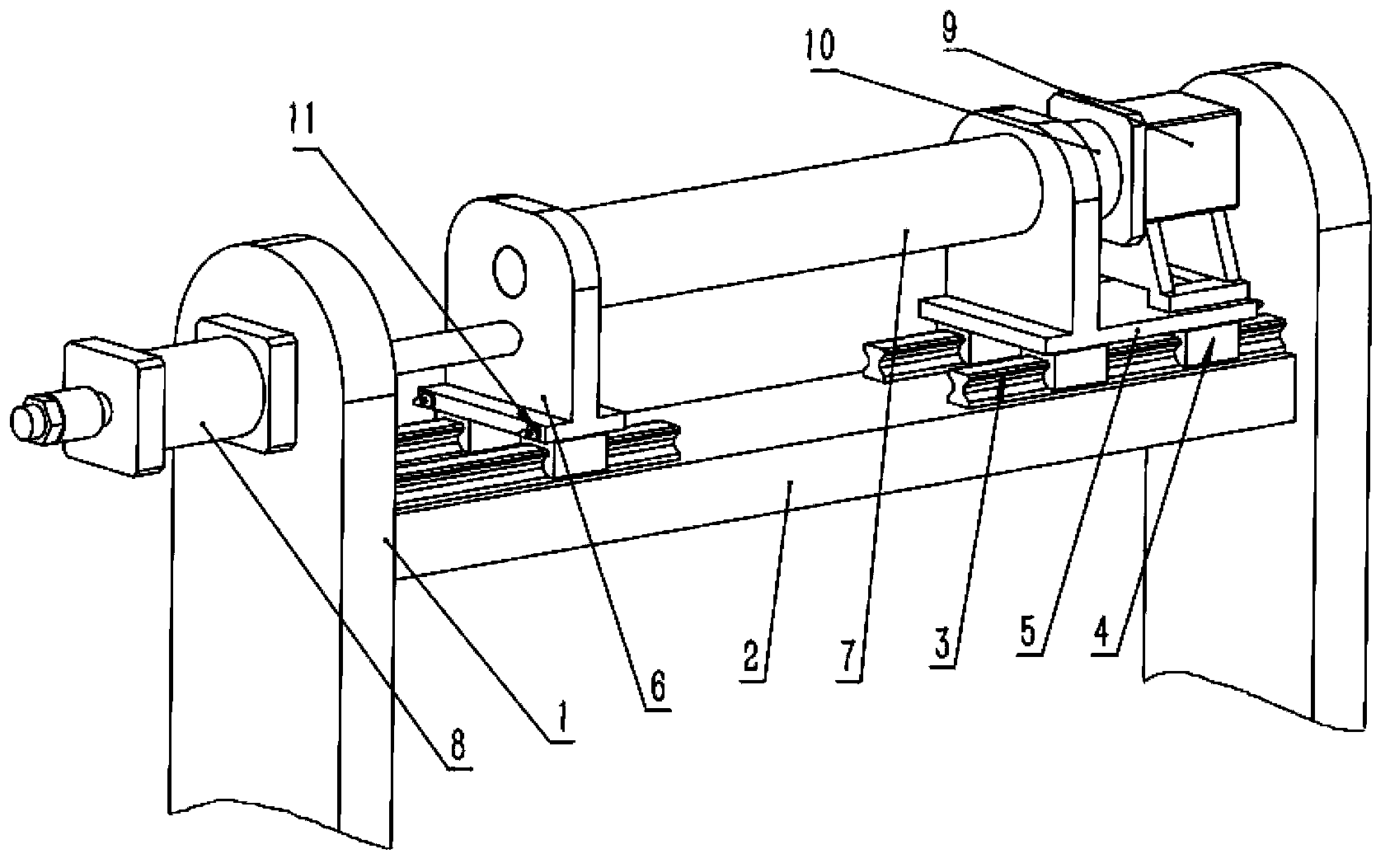

[0014] Example: see figure 1 As shown, a left and right swinging device for a guide roller includes a pillar 1, and the two ends of the crossbeam 2 are fixed on two symmetrical pillars 1, and several groups of guide rails 3 are fixed on the two ends of the crossbeam, and a slide block 4 is inserted on the guide rail 3 , the slider 4 is fixed with the left support 6 and the right support 5, the two ends of the guide roller 7 are fixed on the left support 6 and the right support 5, and the right end of the guide roller 7 is connected with the shaft coupling 10 The rotating shaft of motor 9 is connected together, and motor 9 is fixed on the right support 5;

[0015] Described cylinder 8 adopts adjustable stroke cylinder.

[0016] Described slide block 4 adopts linear bearing slide block.

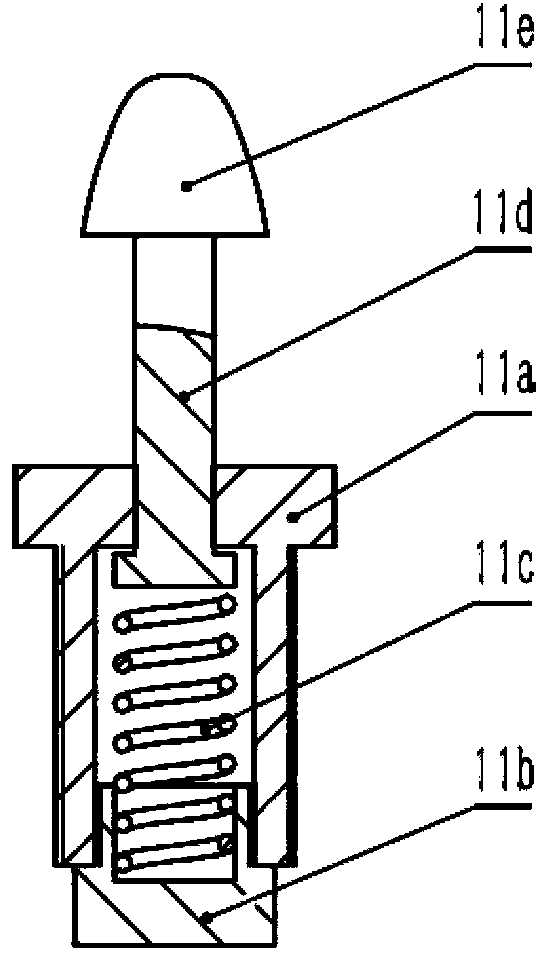

[0017] Anti-collision buffer blocks 11 are provided near the two ends of the pillar 1 on the left and right supports.

[0018] Working principle: The motor 9 drives the yarn guide roller 7 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com