Flow control valve

A technology of flow control valve and valve body, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc. It can solve the problems of difficult passage and unstable flow control of hydraulic oil, and achieve the effect of stable flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are only used to illustrate the possible implementation aspects of the present invention, but they are not intended to limit the scope of protection of the present invention, and are described first.

[0029] See Figure 1 to Figure 6 The figure shown in the figure is the selected embodiment structure of the present invention, which is for illustrative purposes only, and is not limited by this structure in the patent application.

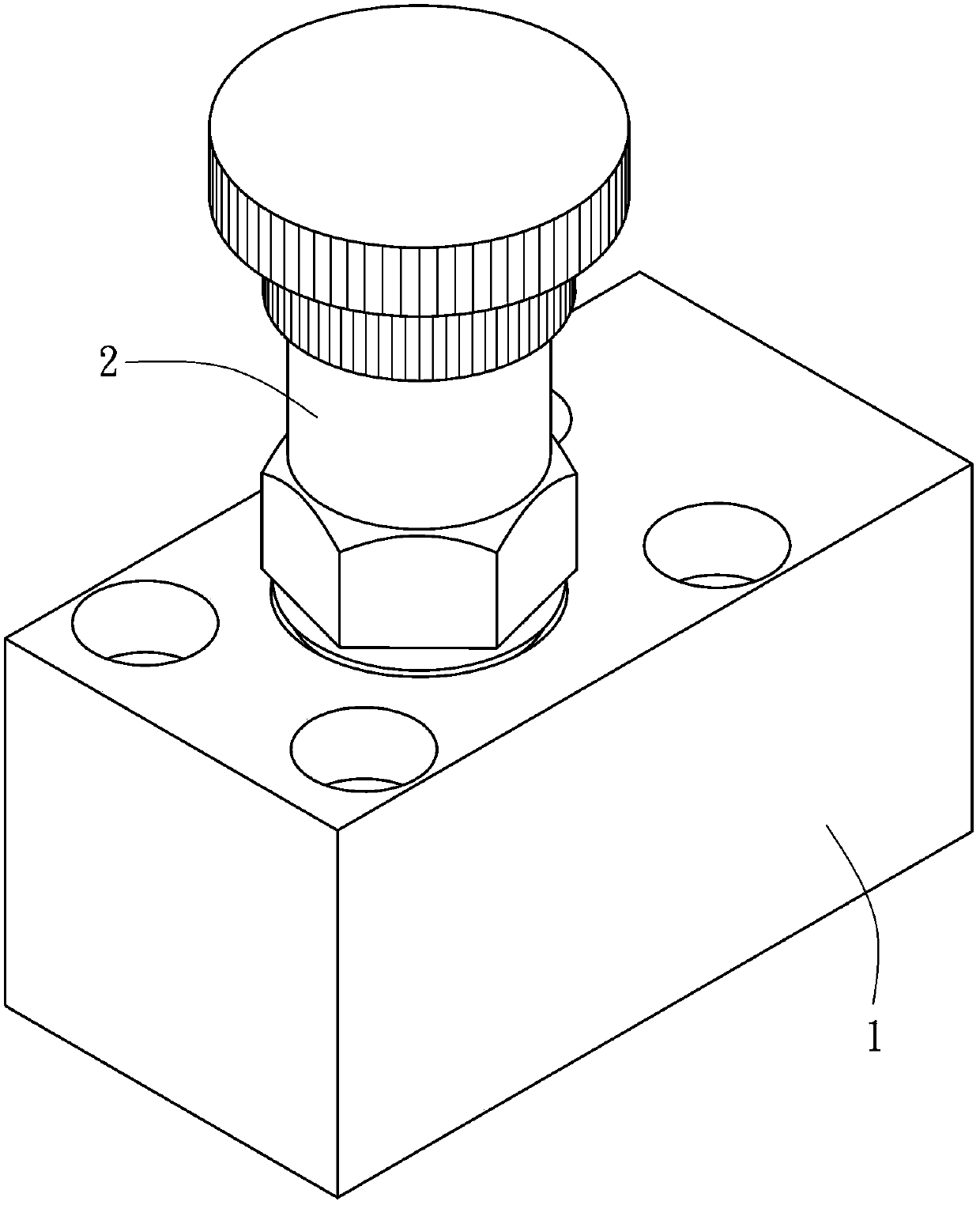

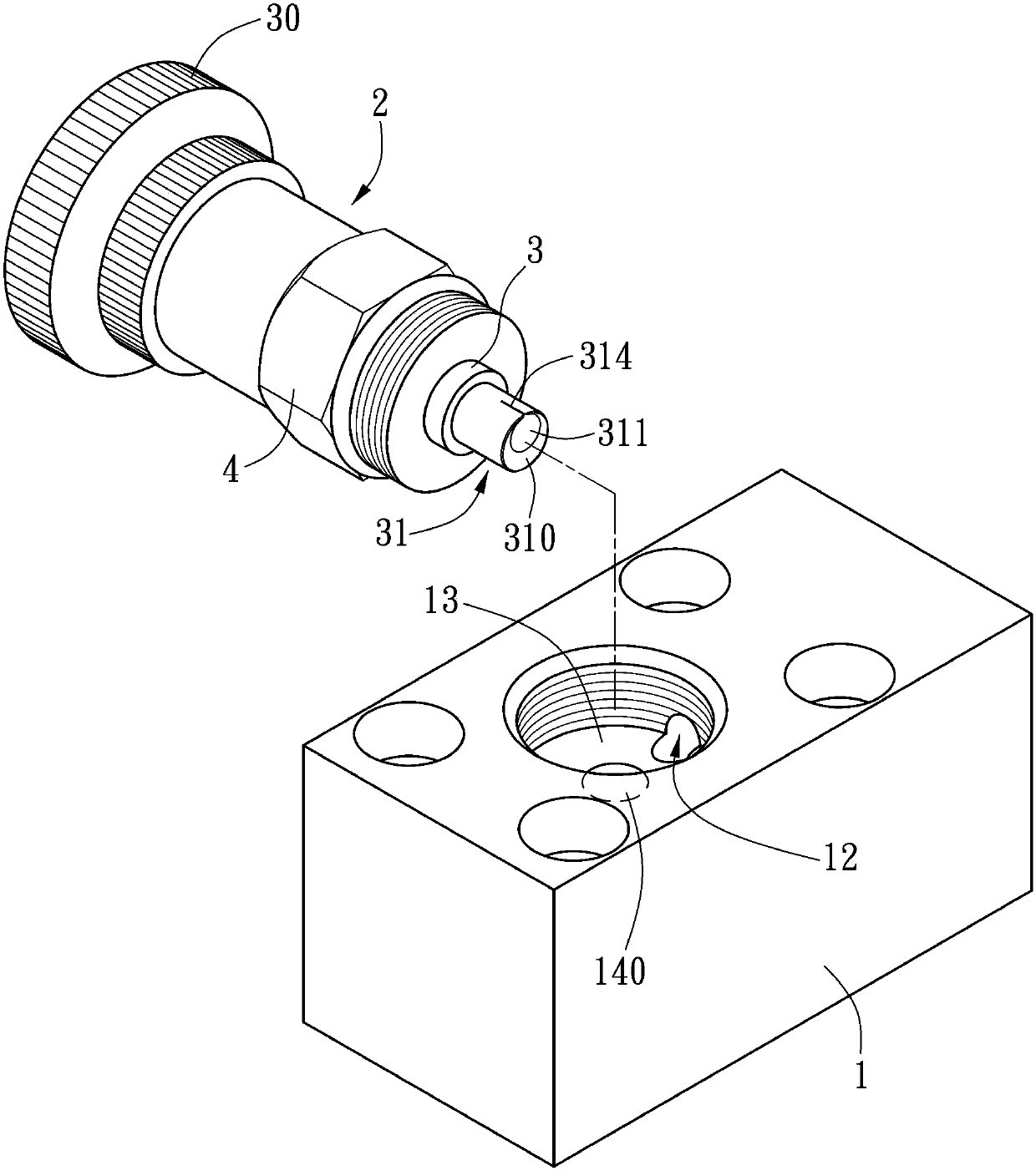

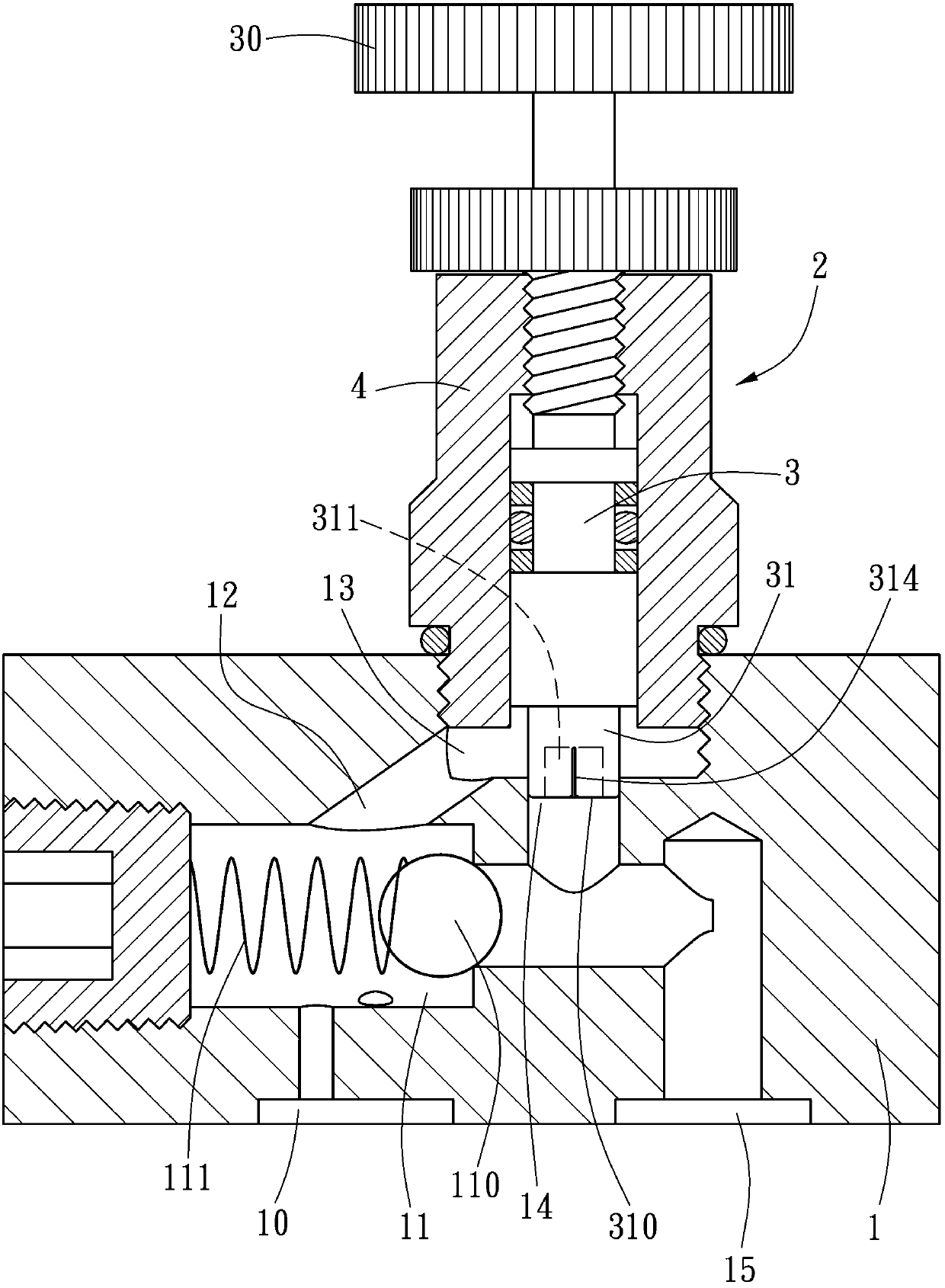

[0030] This embodiment provides a flow control valve, which is as Figure 1 to Figure 2 As shown, it includes a valve body 1 and an adjusting member 2, wherein:

[0031] Such as image 3 As shown, the valve body 1 has a first port 10, a main flow passage 11, a first passage 12, a groove 13, a second passage 14 and a first port 15. The main flow passage 11, the first passage 12 and the second passage 14 are all hidden inside the valve body 1, and the first port 10, the tank 13 and the first port 15 respectively lead to the outs...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap