clutch booster

A booster and clutch technology, applied to clutches, mechanical equipment, etc., can solve the problems of friction plates that cannot be quantified in time to reflect the wear of friction plates, and achieve a reliable and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

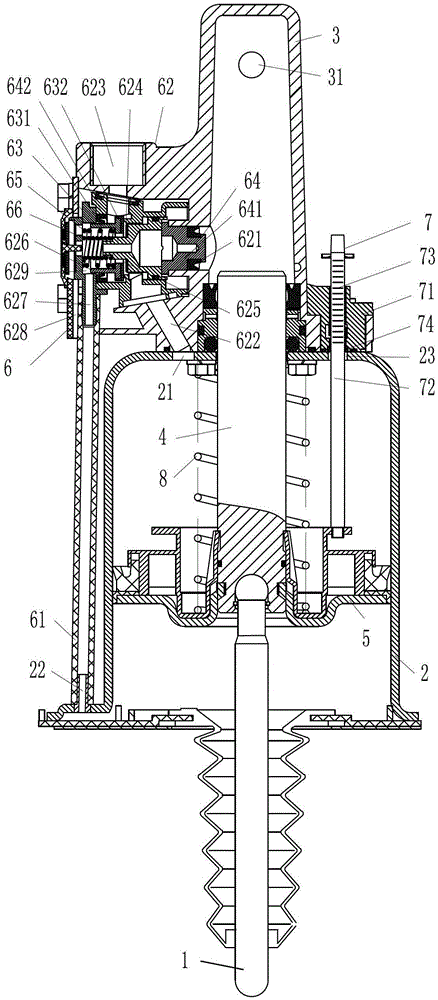

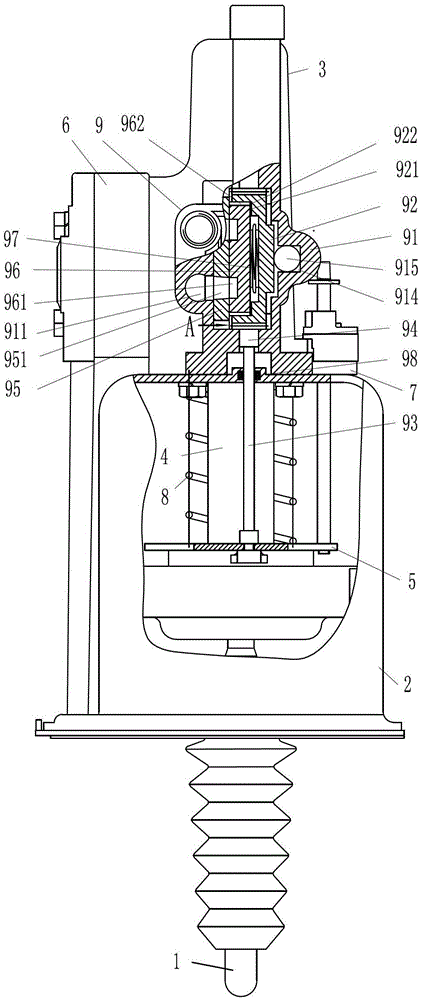

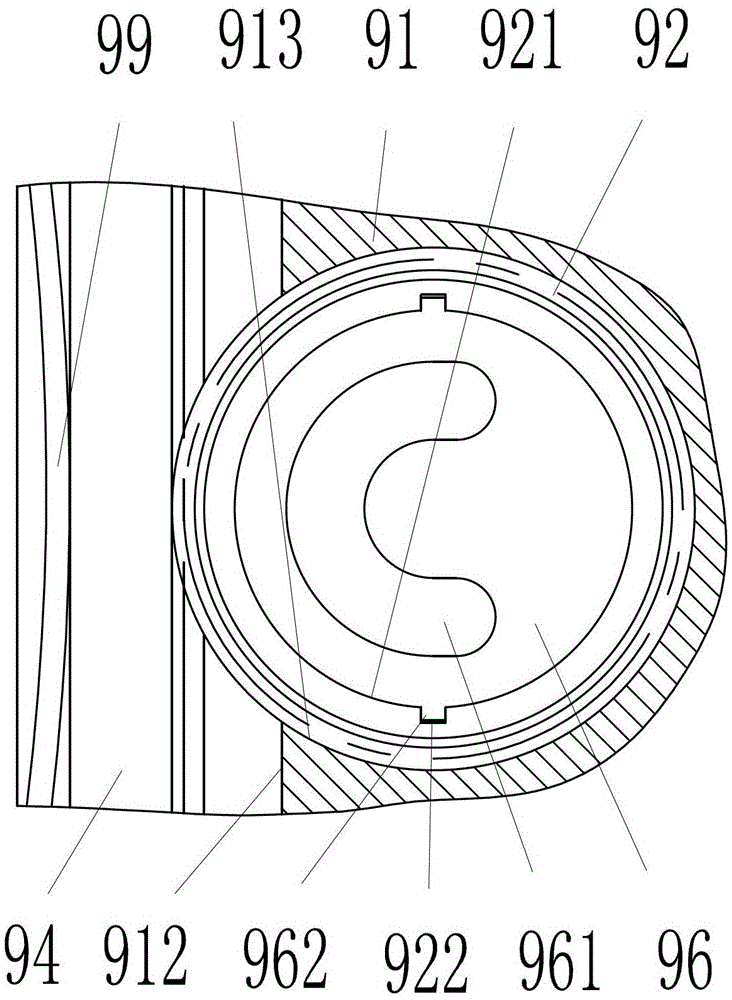

[0018] Embodiment 1, as attached figure 1 Shown: a clutch booster, including a pneumatic cylinder 2 with an air inlet 21 and an exhaust port 22 at the rear end and a front end respectively, a hydraulic cylinder 3 with a liquid inlet 31 connected to the rear end of the pneumatic cylinder 2, and a hydraulic cylinder 3 located at the air pressure Inside the cylinder 2, the two ends are respectively connected with the push rod 1 and the piston 5 of the piston rod 4 whose rear end extends into the hydraulic cylinder 3, the intake and exhaust control valve 6 set on the side wall of the hydraulic cylinder 3, and the friction plate wear measurement device 7 ; There is a return spring 8 between one end of the piston 5 and the pneumatic cylinder 2;

[0019] The friction lining wear measuring device 7 includes a slide bar seat 71 and a slide bar 72 screwed to the rear end of the air cylinder 2; The side circumference of the other end of the slide bar 72 has a dimension marking line 73; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com