Furnace door brick for tapping nozzle

A technology of furnace door bricks and steel nozzles, which is applied in the field of furnace door bricks for tapping nozzles, can solve the problems of smelting work influence, low cost performance, unsatisfactory lifespan, etc., achieve extensive safe operation and use, reduce costs, and benefit safety The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

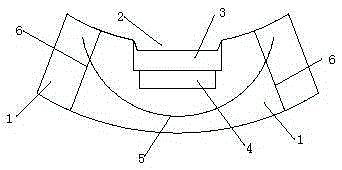

[0016] Combine below figure 1 Specific description embodiment:

[0017] A furnace door brick for a tapping nozzle, characterized in that the furnace door brick for a tapping nozzle includes a prefabricated refractory castable block 1, and a water outlet groove is provided on the inner side of the upper end of the prefabricated refractory castable block 1 2. A trough-type magnesia-carbon brick 3 is provided in the outlet tank 2, and a magnesia-carbon safety brick 4 is provided between the trough-type magnesia-carbon brick 3 and the prefabricated refractory castable block 1, and the refractory castable The material prefabricated block 1 is provided with an arc-shaped rebar 5 and two straight rebars 6, the arc-shaped rebar 5 is consistent with the radian of the outlet tank 2, and the two straight rebars 6 are symmetrically distributed in the arc On both sides of the rebar 5, the two straight rebars 6 are in contact with the curved rebar 5.

[0018] Preferably, the trough-type m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com