Optical detection system, biochemical analyzer, light beam orienting component and adjusting method of optical detection system and biochemical analyzer

An optical detection and beam technology, applied in the optical field, can solve the problem of large, some beams may be projected outside the sample under test or at the critical position between the sample and the container and be reflected or scattered, the test range of the sample under test is small, Affect the accuracy of test results and other issues, to achieve the effect of reducing the difficulty of system debugging, improving flexibility and convenience, and ensuring stability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

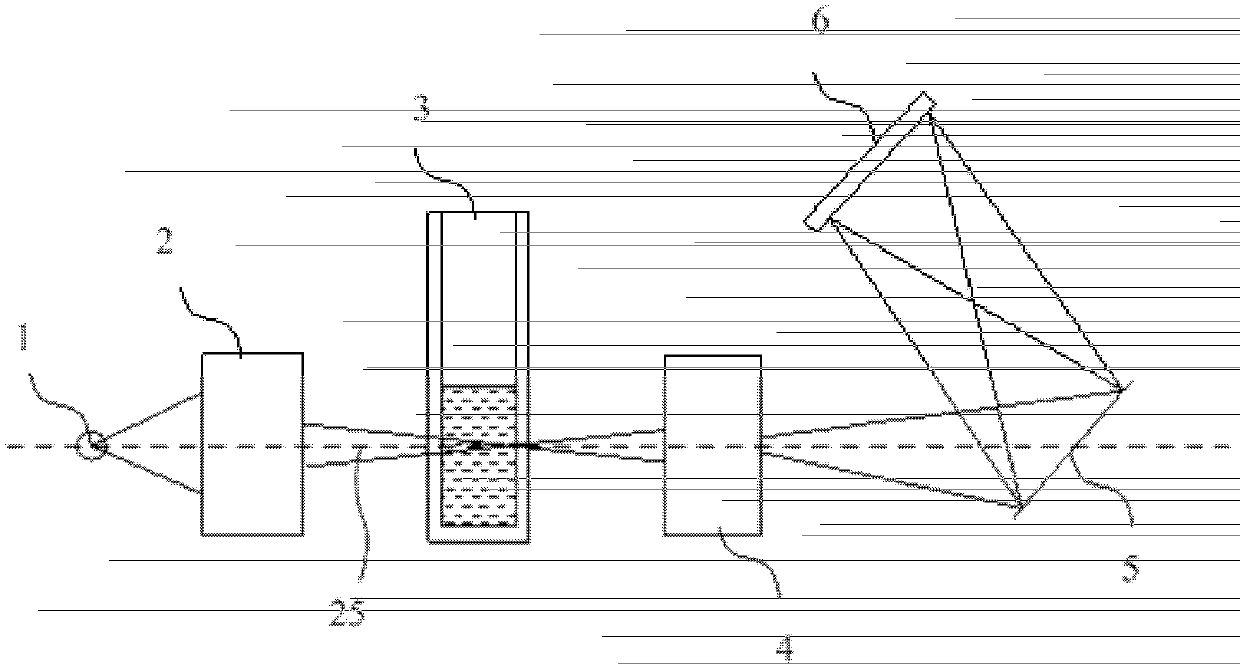

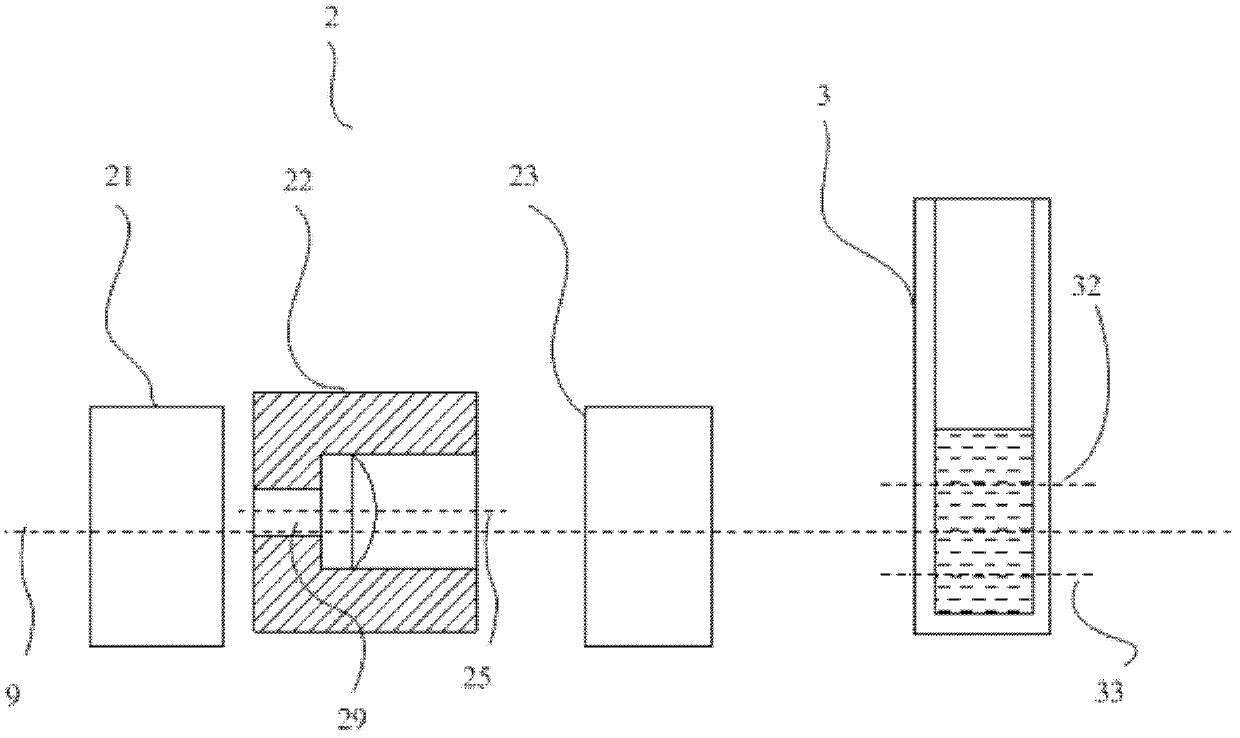

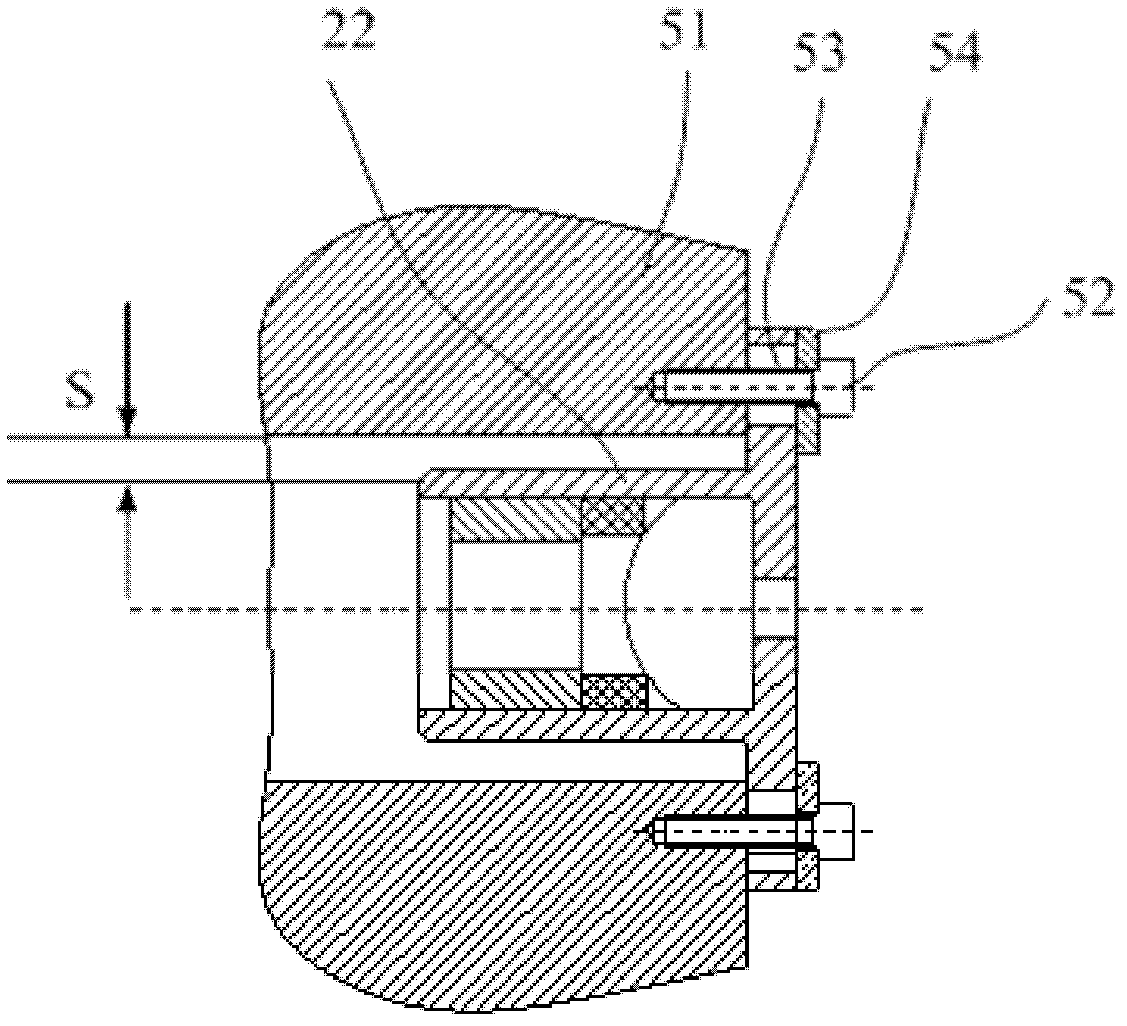

[0045] Such as Figure 1 to Figure 2 As shown, the optical detection system of an embodiment is used to detect the substance components contained in the sample to be tested, which includes a light source 1, a beam orientation component 2, a sample placement position 3, and a light beam arranged in sequence to form a direct light path. Collecting component 4, light splitting component 5 and photodetecting component 6. According to specific needs, each component can be installed on a base that realizes light path sealing, with a certain distance between adjacent components. The measured sample placement position 3 is used to place the measured sample. In this embodiment, the measured sample placement position 3 is located between the beam directing component 2 and the beam collecting component 4. In some embodiments, for example, the measured sample faces the beam In the case of reflection, the sample placement position 3 to be tested may also be located on one side of the beam ...

no. 2 example

[0057] Such as Picture 9 with Picture 10 As shown, the optical detection system of this embodiment includes a light source 1, the beam orientation component described in the first embodiment, a sample placement position 3, a beam collection component, a spectroscopic component, and a photodetection component, as well as a light path reflex component 24. The light path folding component 24 has a reflective surface 241. In this embodiment, the beam adjusting component 22 is located on the rear side of the light path folding component 24. The light incident surface of the light beam adjusting component 22 in the light source 1 and the beam directional component is the same as the reflecting surface 241. In contrast, after the light beam generated by the light source 1 is reflected by the reflecting surface 241, the incident light beam 41 is formed and enters the beam adjusting component 22. In some embodiments, the beam adjusting component 22 may also be located on the front side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com