Online cold-rolled steel strip shape statistic method

A cold-rolled strip, statistical method technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of inaccurate statistical results of the fluctuating critical shape value, achieve reduced losses, improve hit rate, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

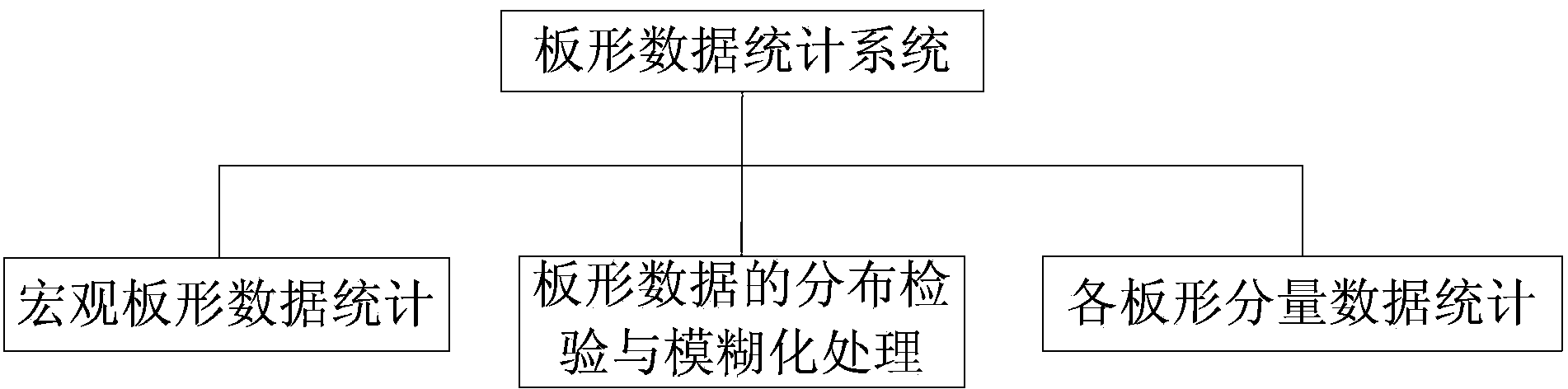

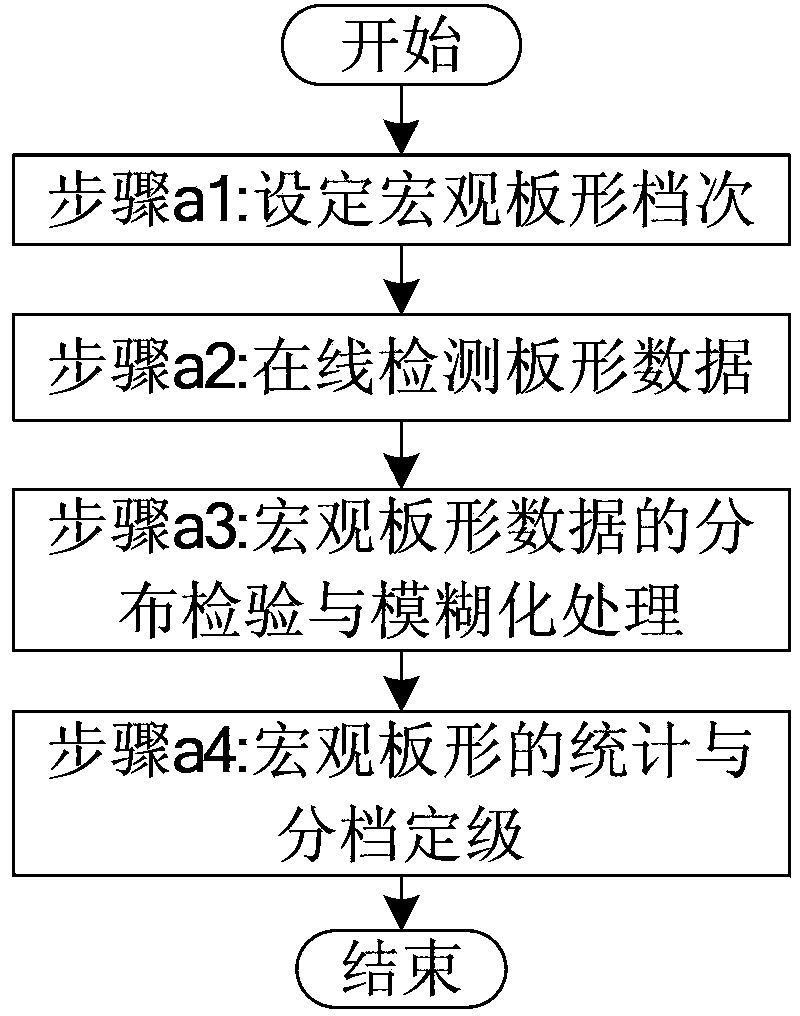

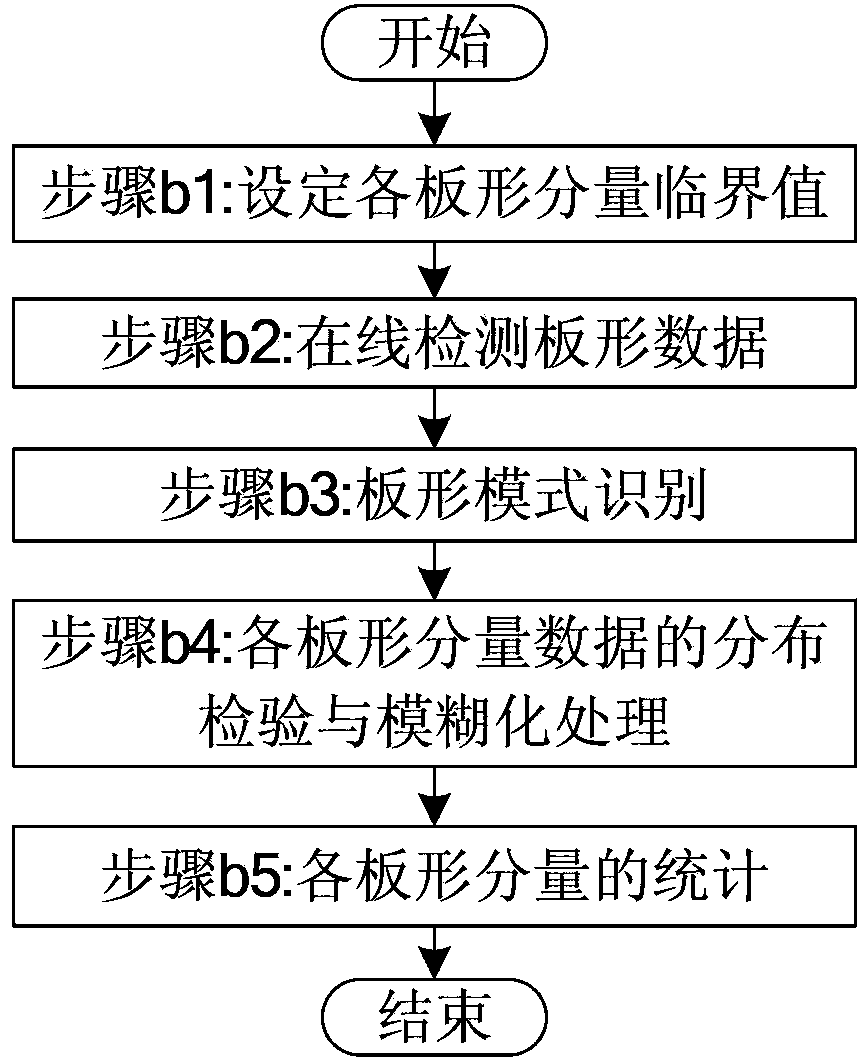

[0046] Figure 1 to Figure 4 It is the calculation flow chart of the flatness on-line statistical method of the present invention. Taking the online detection data of one coil of strip steel of a certain 1050 rolling mill as an example, an online flatness statistical model of cold-rolled strip is established. Collect the plate shape data of the sixth pass, the entrance thickness is 0.42mm, the exit thickness is 0.29mm, and the width is 910mm.

[0047] First, set the macro shape grade level, the list is as follows:

[0048] Shape grade

Class I

Class II

Class IV

Class V

Level VI

Set critical shape value

≤4I

≤6I

≤8I

≤12I

≤16I

≤20I

Statistical probability of macro flat shape

[0049] Then, set the critical flatness value of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com