Dielectric Barrier Discharge Lamps

A dielectric barrier, discharge lamp technology, applied in the direction of discharge lamps, gas discharge lamps, gas discharge lamp parts, etc., can solve problems such as breakage, cracks, and discharge vessel damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

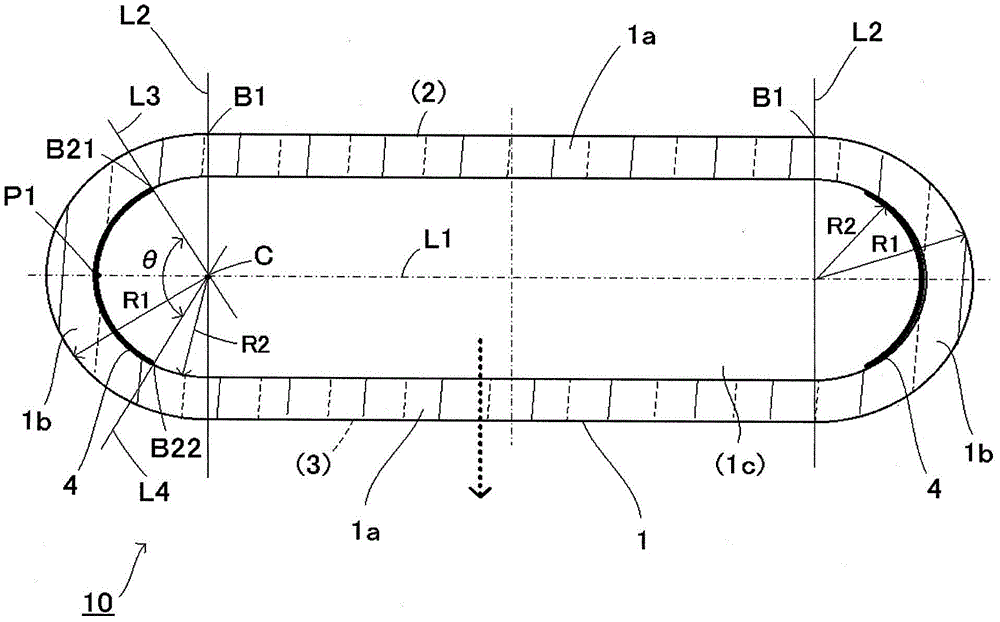

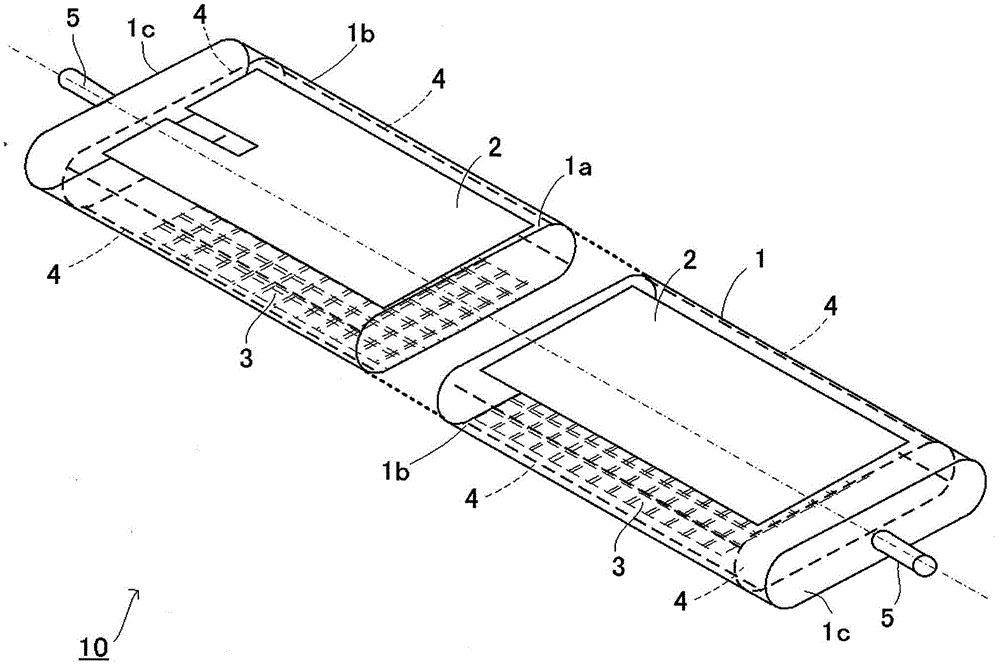

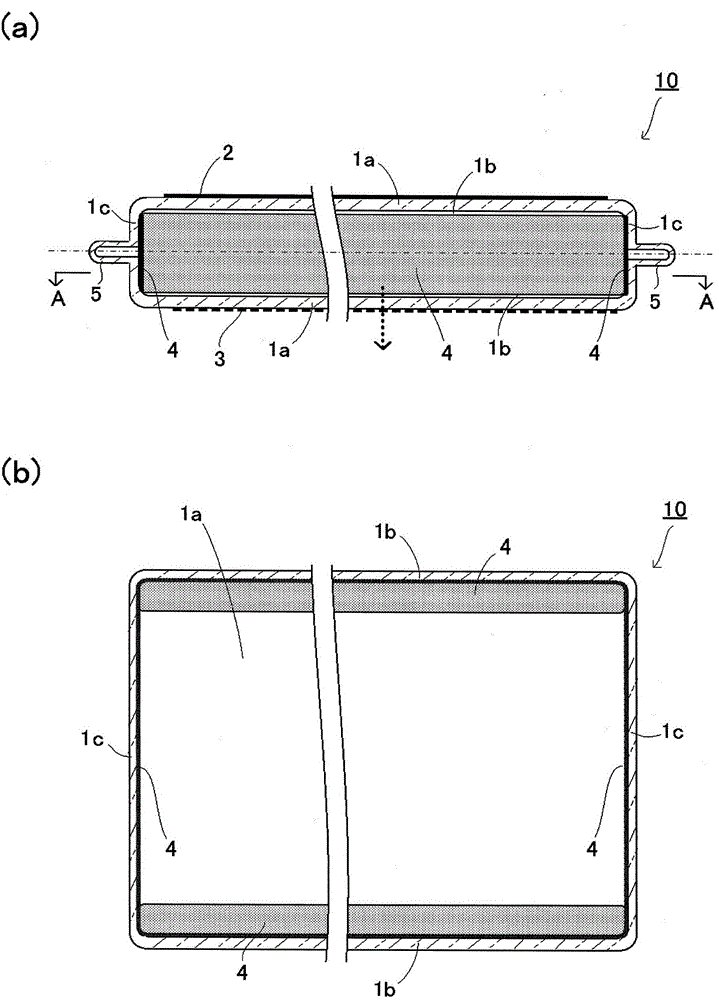

[0096] figure 2 and image 3 It is a figure which shows an example of the 1st Embodiment of this invention, figure 2 It is a perspective view omitting the vertically long central part of the dielectric barrier discharge lamp, image 3 yes figure 2 cutaway view. image 3 (a) is to figure 2 The sectional view obtained by cutting the discharge vessel at the longitudinal central axis and viewing it from the side direction, image 3 (b) is along image 3 A-A line cross-sectional view seen in the arrow direction of (a). In addition, the one-dot chain line in a figure shows the vertically long central axis.

[0097] It should be noted, figure 2 and image 3 The structure is the same as that of the first aspect, so the description is omitted.

[0098] Figure 10 It is a figure which shows an example of 1st Embodiment of this invention, and is a cross-sectional view perpendicular to the longitudinal direction of a dielectric barrier discharge lamp. Figure 10 The singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com