Anti-vibration elastic dedicated movable joint for temperature sensor

A technology of temperature sensors and joints, applied in the field of sensors, can solve problems such as damage to temperature measuring elements, influence on measurement accuracy, unsafe welding, etc., and achieve the effect of reducing vibration and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

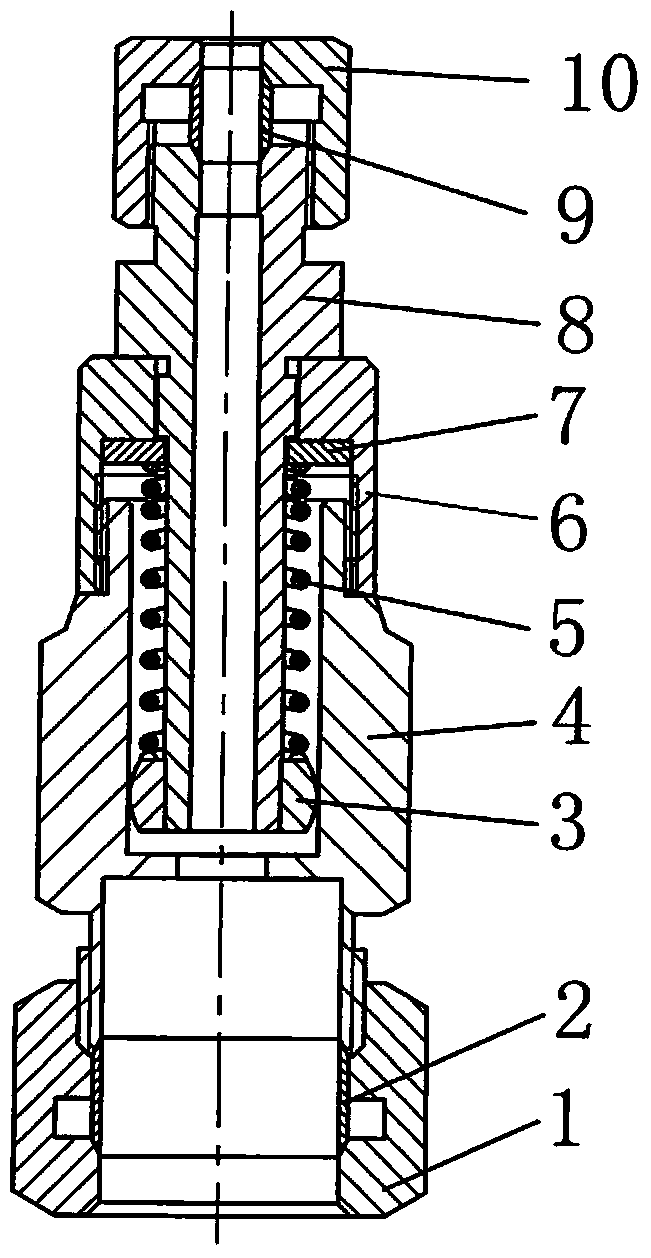

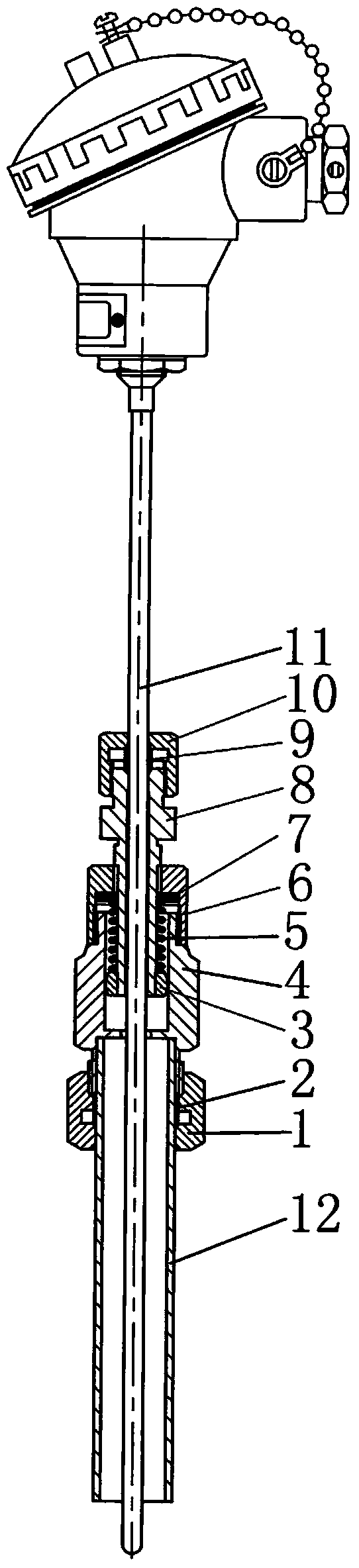

[0011] Such as figure 1 As shown, it is a schematic diagram of the structure of the shockproof elastic joint used for the temperature sensor, which consists of the lower ferrule nut (1), the lower movable ferrule (2), the inner retaining ring (3), the ferrule bolt (4), the spring ( 5), nut sleeve (6), washer (7), ferrule screw (8), upper movable ferrule (9), upper ferrule nut (10), composed.

[0012] Choose the lower ferrule nut (1), the lower movable ferrule (2), the inner retaining ring (3), the ferrule bolt (4), the nut sleeve (6), the washer (7), and the ferrule of the ordinary stainless steel series. The movable ferrule (9) on the cover screw (8) and the ferrule nut (10) select spring steel to make the spring (5),

[0013] Put the lower movable ferrule (2) in the lower ferrule nut (1), the ferrule bolt (4) is threadedly connected with the lower ferrule nut (1), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com