Impeller aerator

An aerator and impeller technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of limited plastic strength, easy rust process, easy damage, etc., to achieve no welding, reliable and firm connection, power matching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

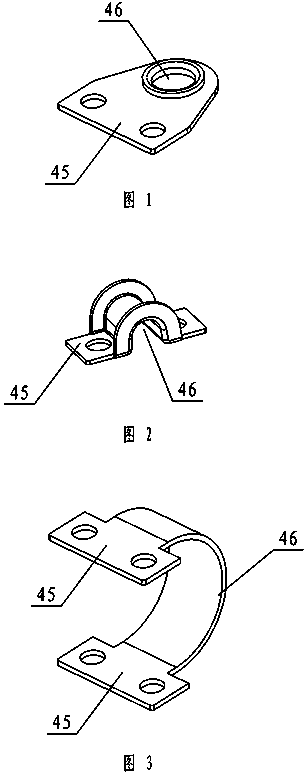

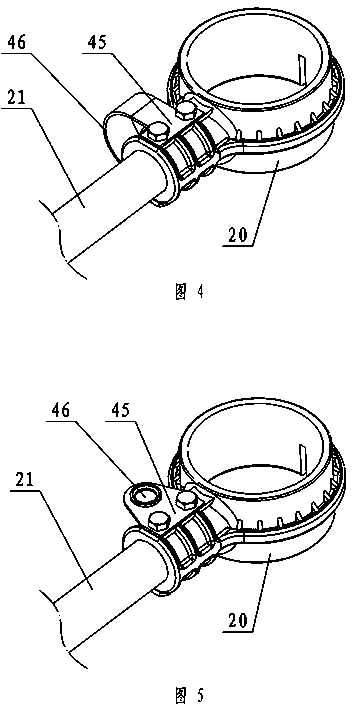

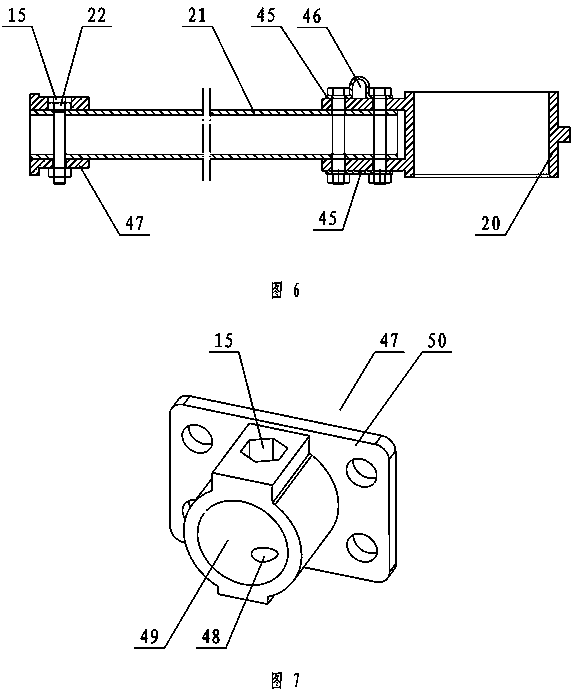

[0047] The present invention will be further described below with specific embodiment, see Figure 1-26 :

[0048] An impeller type aerator, including a motor 27, a reduction box, an impeller, a support rod 21, and a floating body 19. The motor 27 is vertically installed on the reduction box, and the decelerated output shaft 10 protrudes downwards, with a flange 44 at the end It is connected with the fixed seat 33 of the impeller, and there are three substantially evenly distributed connection positions 25 on the outside of the reduction box, and the support rod 21 is fixed on the connection position 25. The connecting seat 47 has an inner hole 49 matched with the steel pipe, and the side has a positioning hole intersecting with the inner hole 49. One side of the positioning hole is a hexagonal through hole 15, and the other side is a round through hole 48. The hexagonal head of the hexagonal bolt enters the hexagonal through hole. Holes 15, hex bolts 22 fasten the connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com