Automatic cutter-feeding pipeline profiling groove tool device

A technology of pipe profiling and automatic feeding, which is used in manufacturing tools, metal processing machinery parts, feeding devices, etc., can solve problems such as size and quality that do not meet specifications, and achieve the effect of real-time adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

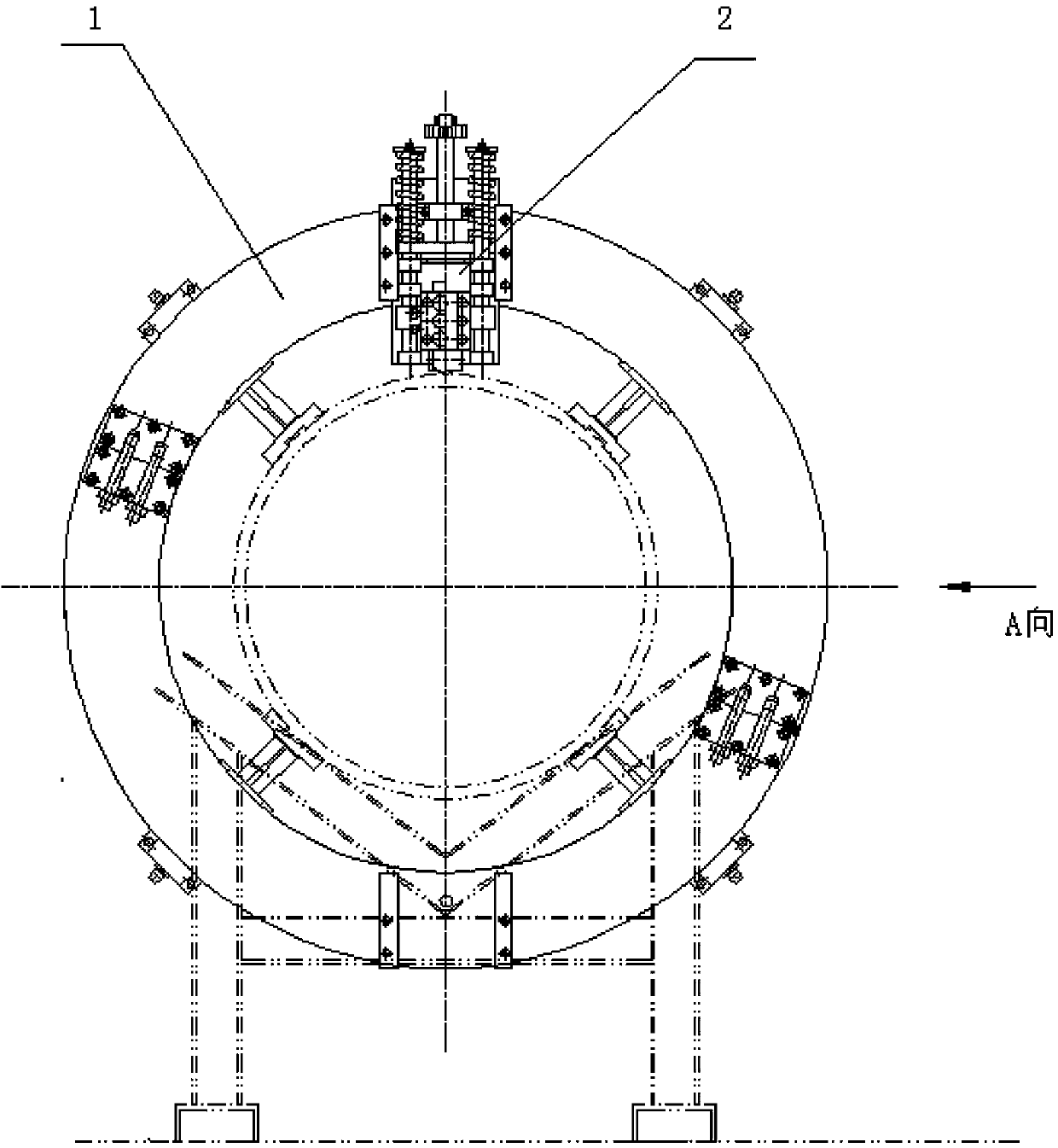

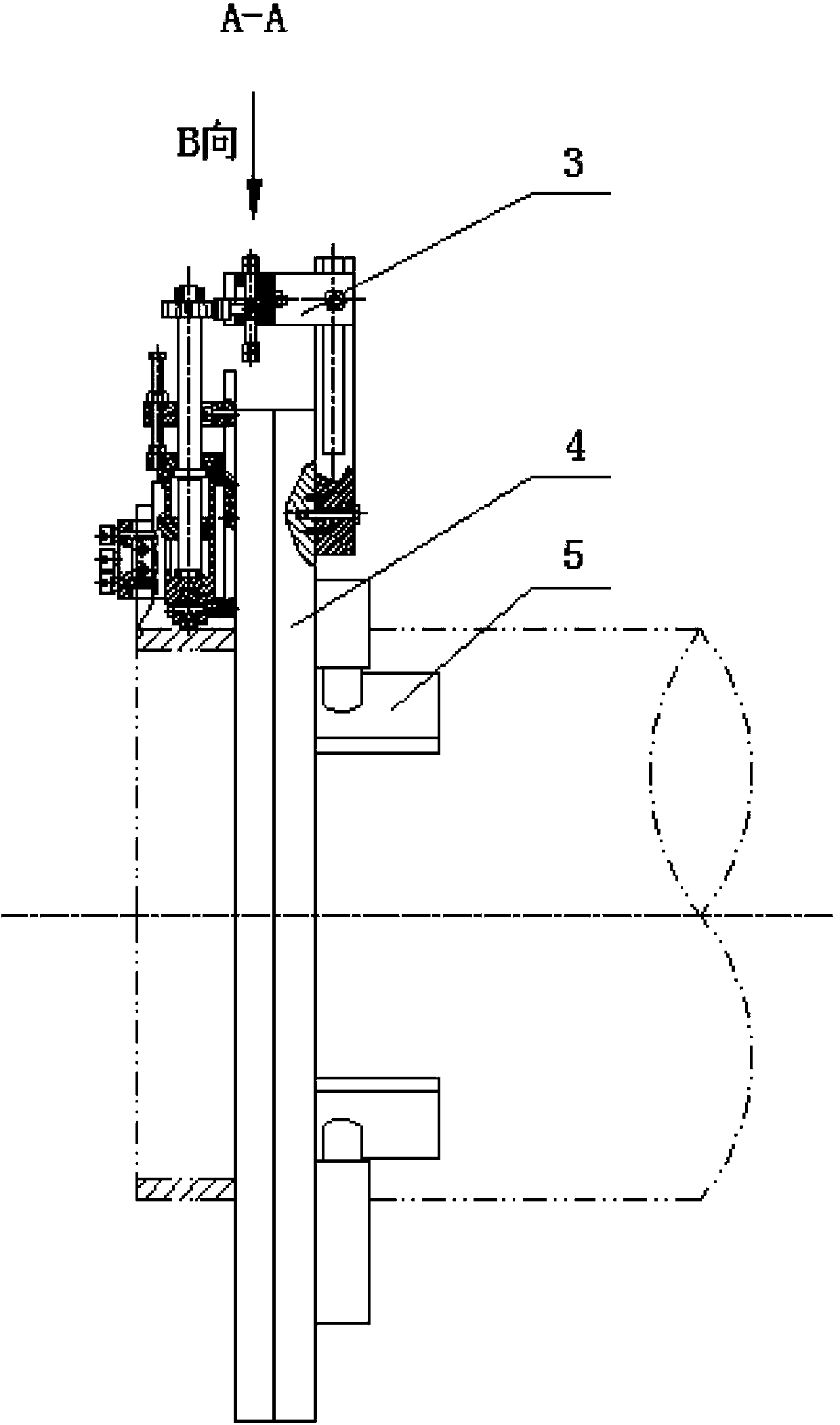

[0034] like figure 1 , 2 As shown, the pipeline profiling bevel tooling tool with automatic knife feeding of the present invention has a profiling bevel tool holder assembly 2 and a fixed stopper assembly 3, wherein the profiling bevel tool rest assembly 2 is installed on the pipe cutting machine The front end face of the movable disk 1 and the fixed block assembly 3 are installed on the rear end face of the fixed seat 4 of the pipe cutting machine, and cooperate with the profiling groove tool holder assembly 2 to perform automatic and intermittent cutting radial feed motion.

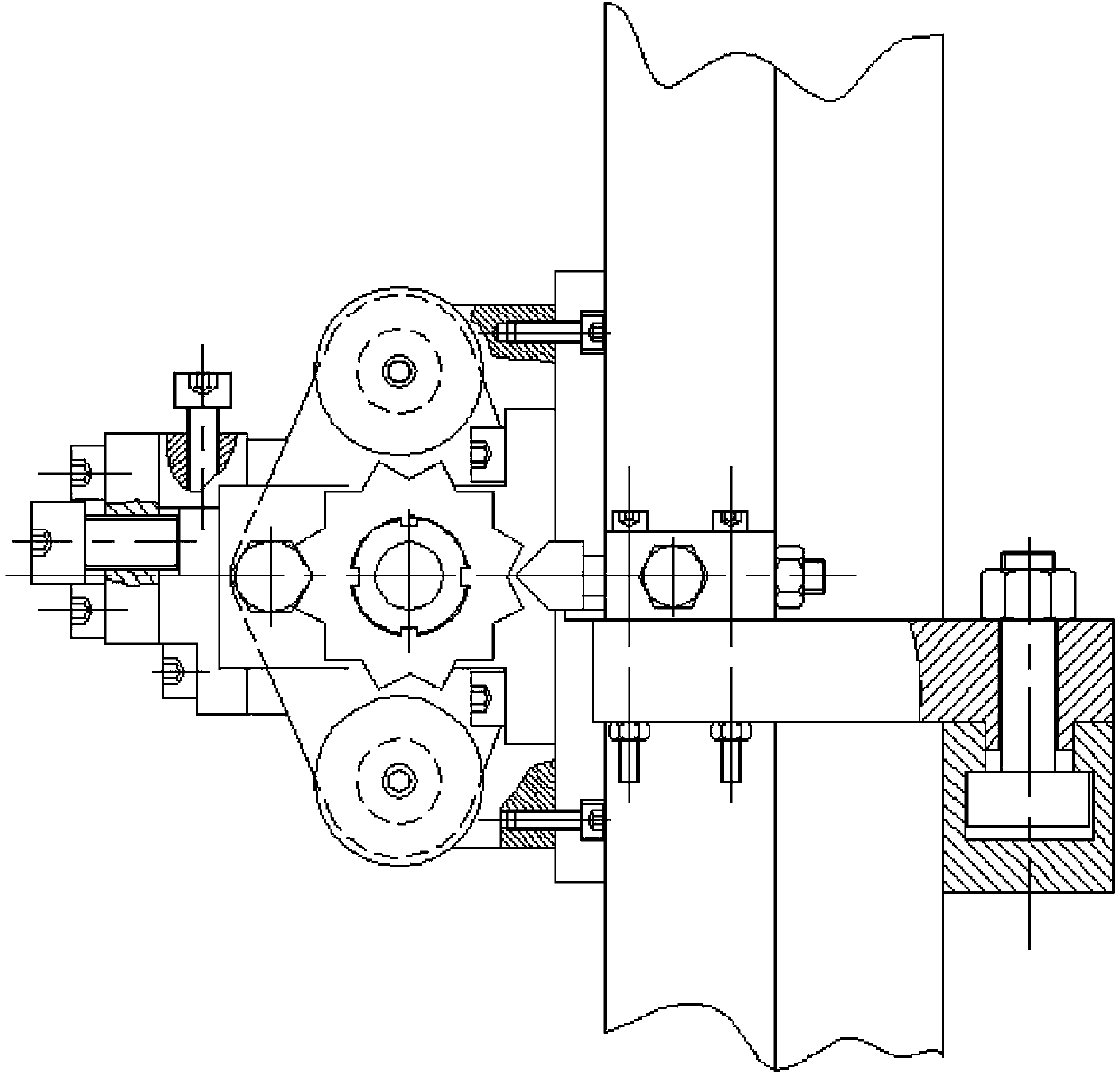

[0035] like image 3 , 4 As shown, the profiling bevel tool holder assembly 2 is installed on the front end of the movable plate 1 of the pipe cutting machine through the bottom plate 213, including a fixed support seat 207, a cylindrical linear guide rail 218, a U-shaped tool seat 210 and a floating cylinder 209 , Two cylindrical linear guide rails 218 arranged in parallel are installed on the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com