Sampling method for quality inspection of tubesheet forgings of reactor steam generator

A technology of steam generator and quality inspection, applied in sampling devices and other directions, can solve the problems that mass production cannot meet the quality and construction period, and achieve the effect of guaranteeing quality and schedule requirements, saving costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings:

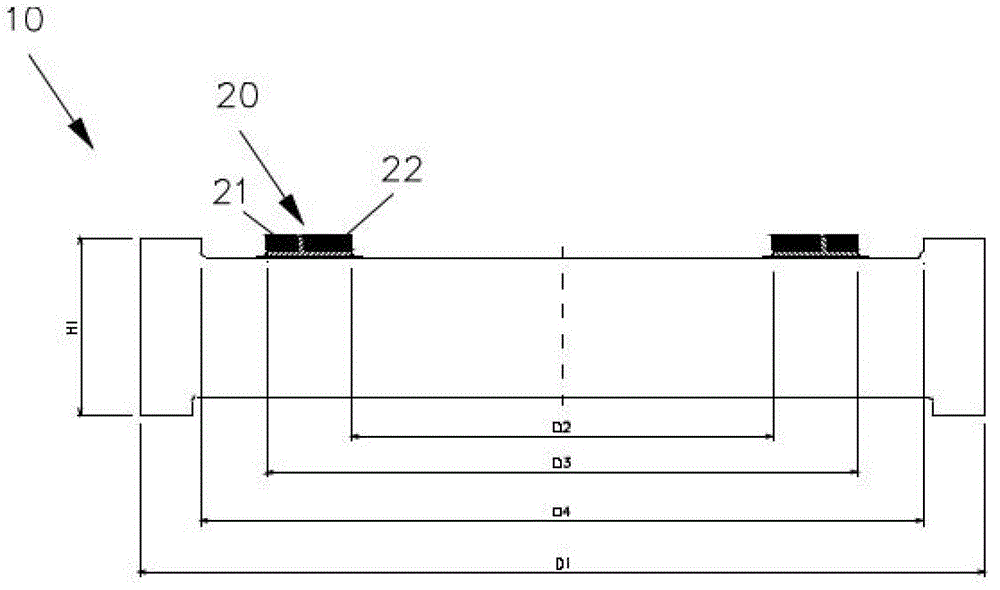

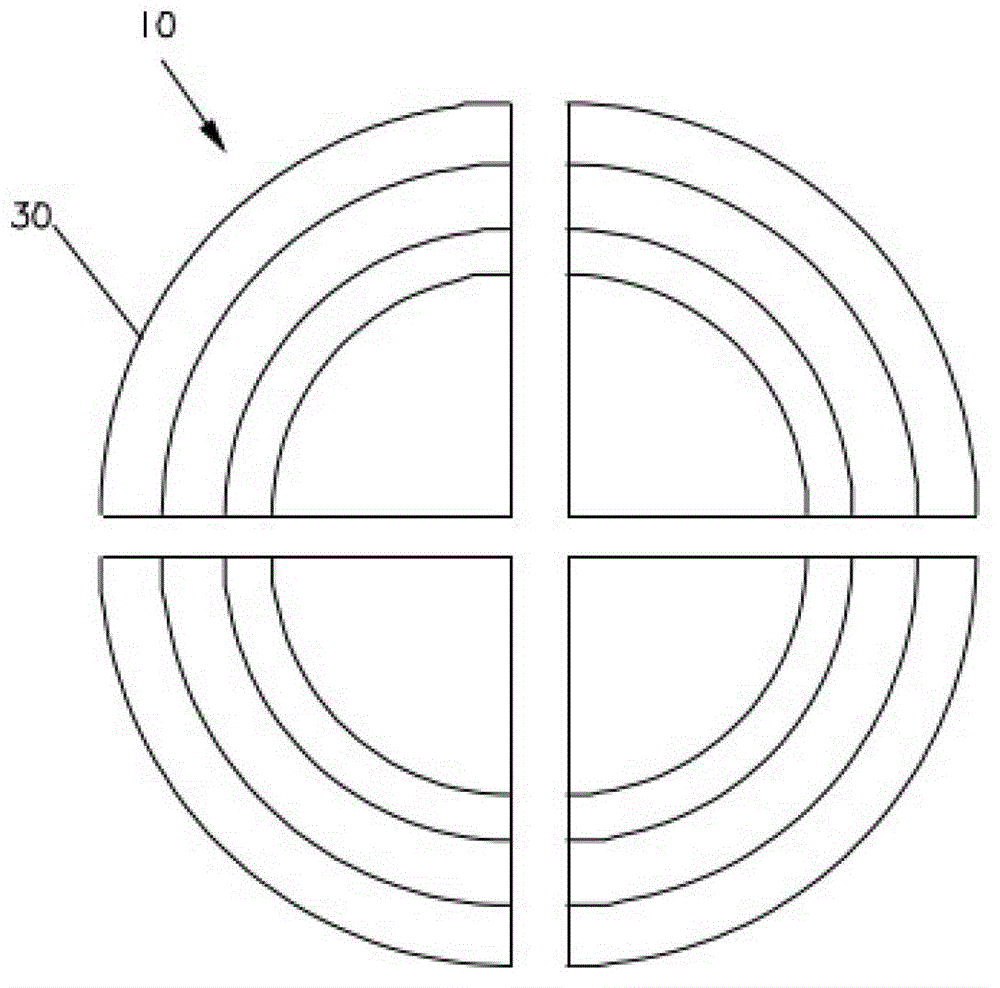

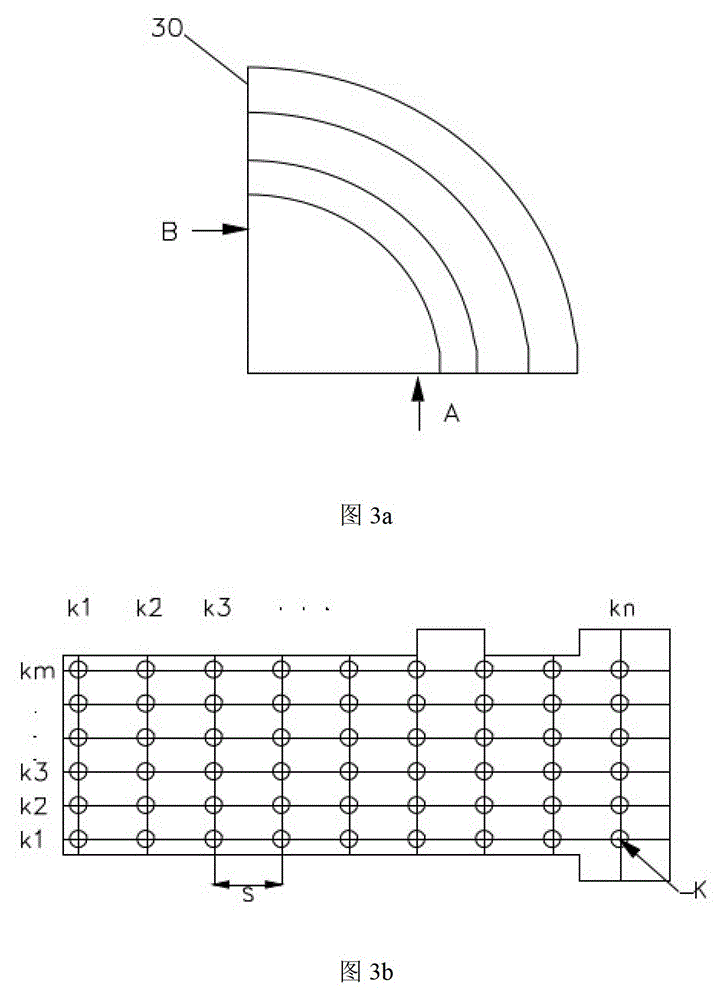

[0048] Combined with the difficulties in the use and manufacturing process of the steam generator tube sheet forging 10, the study considers that the core of the component is the key area for inspection, and the sampling position of the conventional acceptance test can only be on the outer surface of the end of the tube sheet forging 10, so , the performance obtained by the routine acceptance test can not yet represent the quality status of the tube plate forging 10 core. Therefore, it is necessary to carry out anatomical inspection on the inside of the tube plate forging 10 through the opportunity of evaluation while sampling the sampling position of the routine acceptance test, and conduct a comprehensive evaluation of the internal quality of this type of forging made by the manufacturer to accurately Judging the overall quality of the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com