Windmill blade crack detection method

A wind turbine blade and crack detection technology, which is applied in the processing of the detected response signal and the use of acoustic wave emission technology for material analysis, etc., can solve the problem that the signal features are difficult to extract the wind turbine blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Further describe content of the present invention below in conjunction with accompanying drawing and embodiment of description:

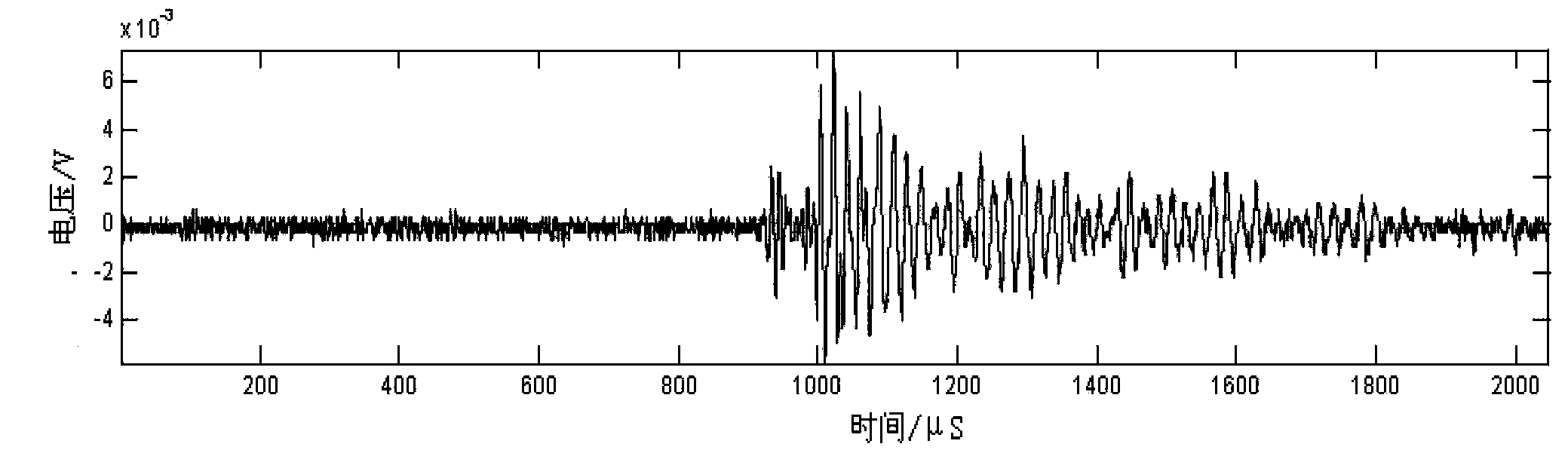

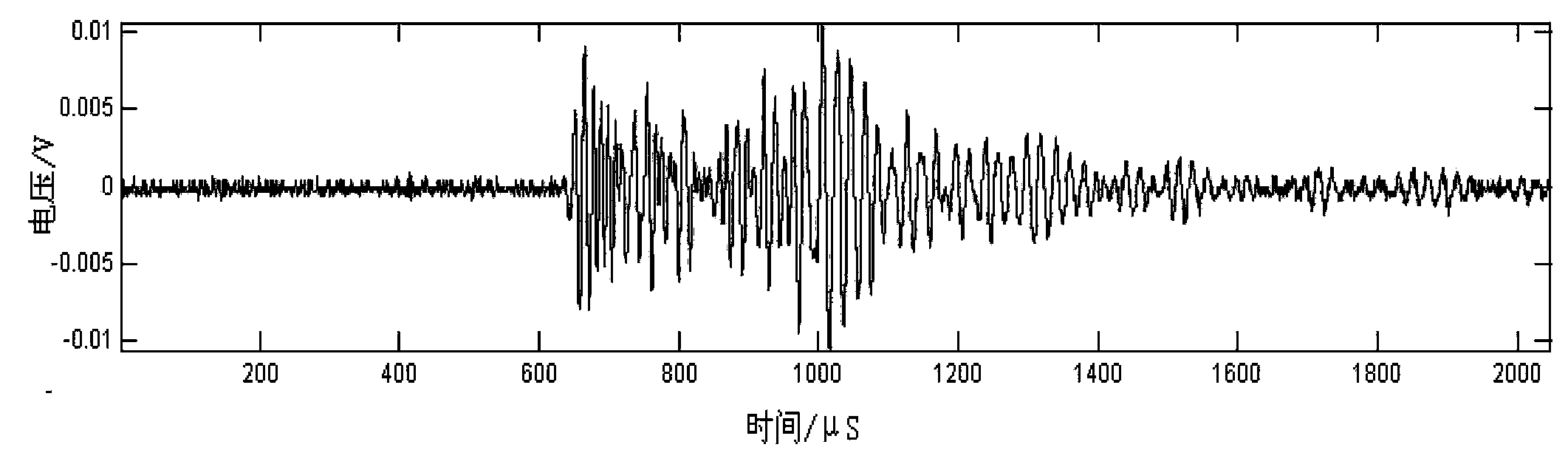

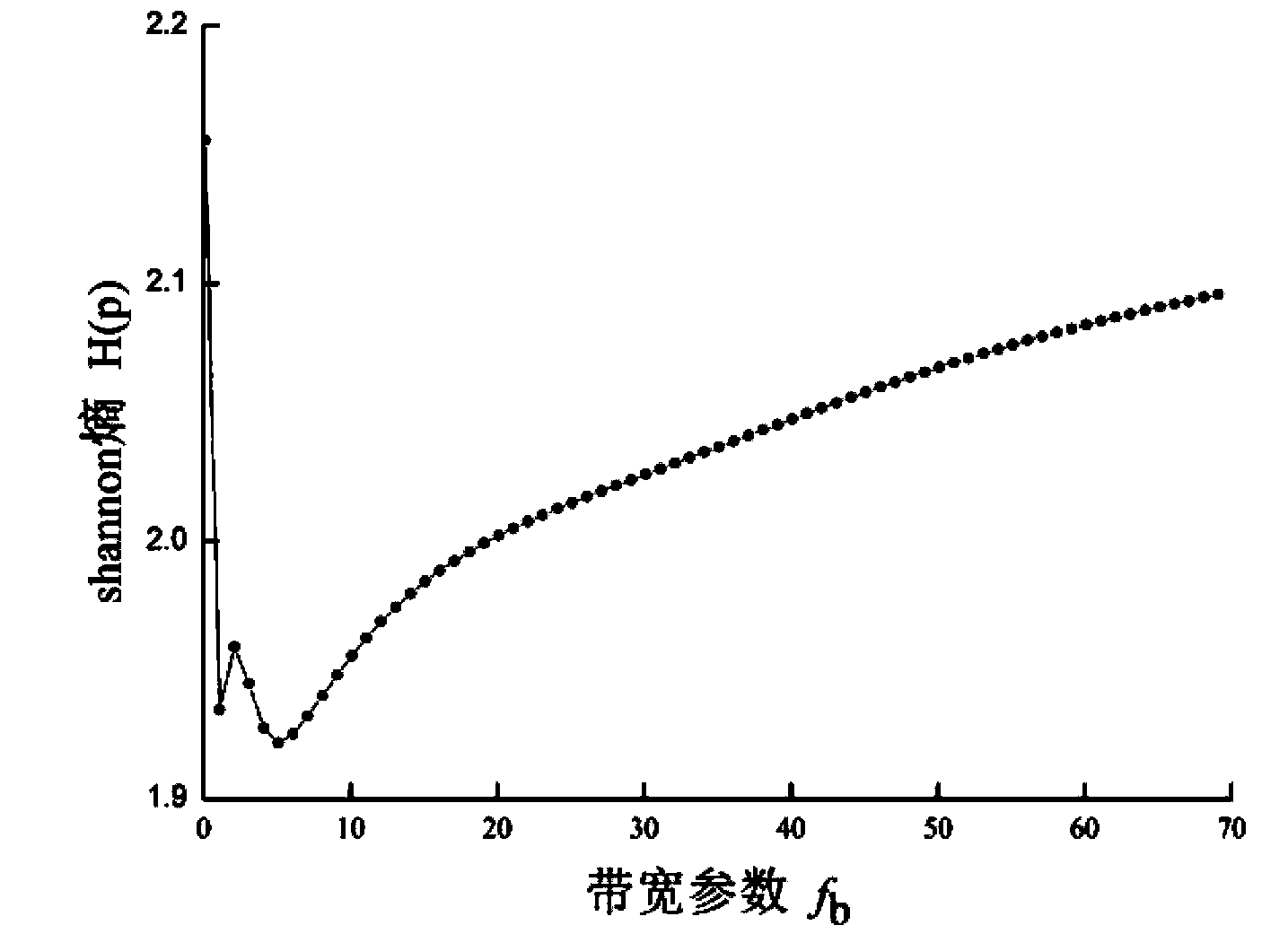

[0044]This wind turbine blade crack detection method first installs an acoustic emission sensor on the wind turbine blade, and transmits the received acoustic emission signal to the PCI-2 acoustic emission acquisition system of PAC Corporation of the United States to determine the sampling frequency and sampling length of the signal , filtering frequency and other acquisition parameters; then based on the Shannon entropy theory, the redistribution scale spectrum basis function bandwidth parameters of the acoustic emission signals of the expanding crack and the crack initiation were calculated, and the Morle wavelet basis function most suitable for the two types of crack acoustic emission signals was obtained. The optimized wavelet basis function calculates the redistributed scale spectrum to extract the time-frequency characteristics of the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com