A structure of bare fiber hot-melt unit

A bare fiber, hot-melt technology, applied in the coupling of optical waveguide, etc., can solve the problems of on-site fusion splicing failure, damage to bare fiber, burnt bare fiber, etc., to achieve enhanced strength and isolation, ensure firm fixation, and controllable length good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

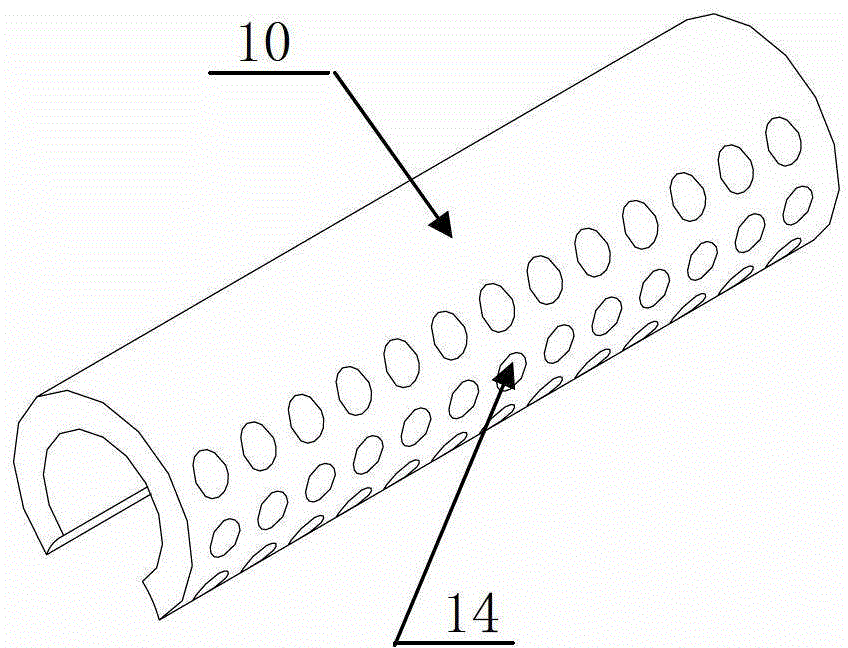

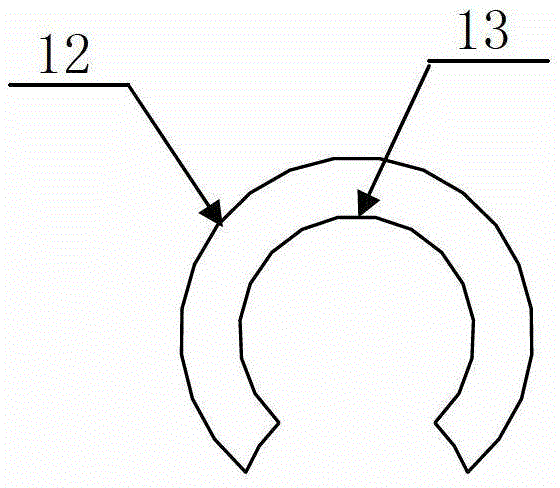

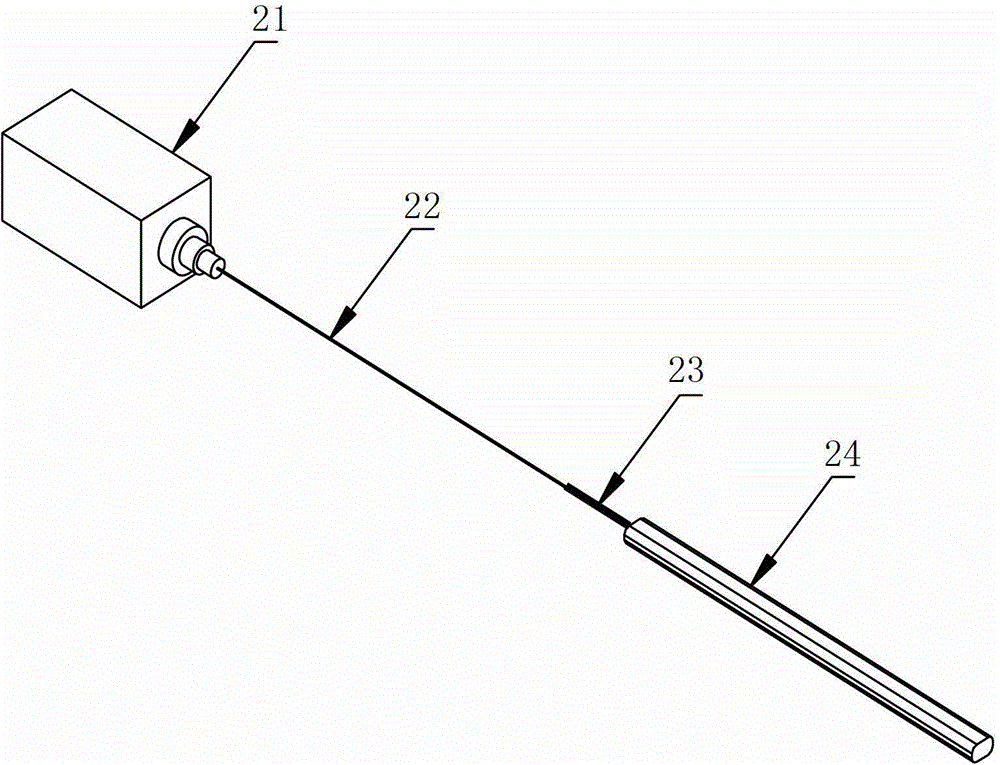

[0025] see Figure 1a , 1b , in the present invention, a bare fiber protection tube 10 is placed on the outer surface of the fused bare fiber. The bare fiber protection tube 10 is a long tube, and the size in the length direction can be determined according to requirements, and it is coated on the outer surface of the bare fiber. The bare fiber in the present invention is a standard bare fiber with a diameter of 0.125mm, which is molded by SMC composite material. SMC (abbreviation for Sheetmouldingcompound) is a sheet molding compound. The design is easy and flexible, and its mechanical properties can be compared with some metal materials. The products manufactured by it have the advantages of good rigidity, deformation resistance, and wide temperature range.

[0026] The tube length direction of the bare fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com