Liquid cooled motor

A liquid-cooled motor and liquid-cooled technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of inability to realize circulating cooling, reduced cooling efficiency of liquid cooling devices, and inconvenient cleaning of flow channels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

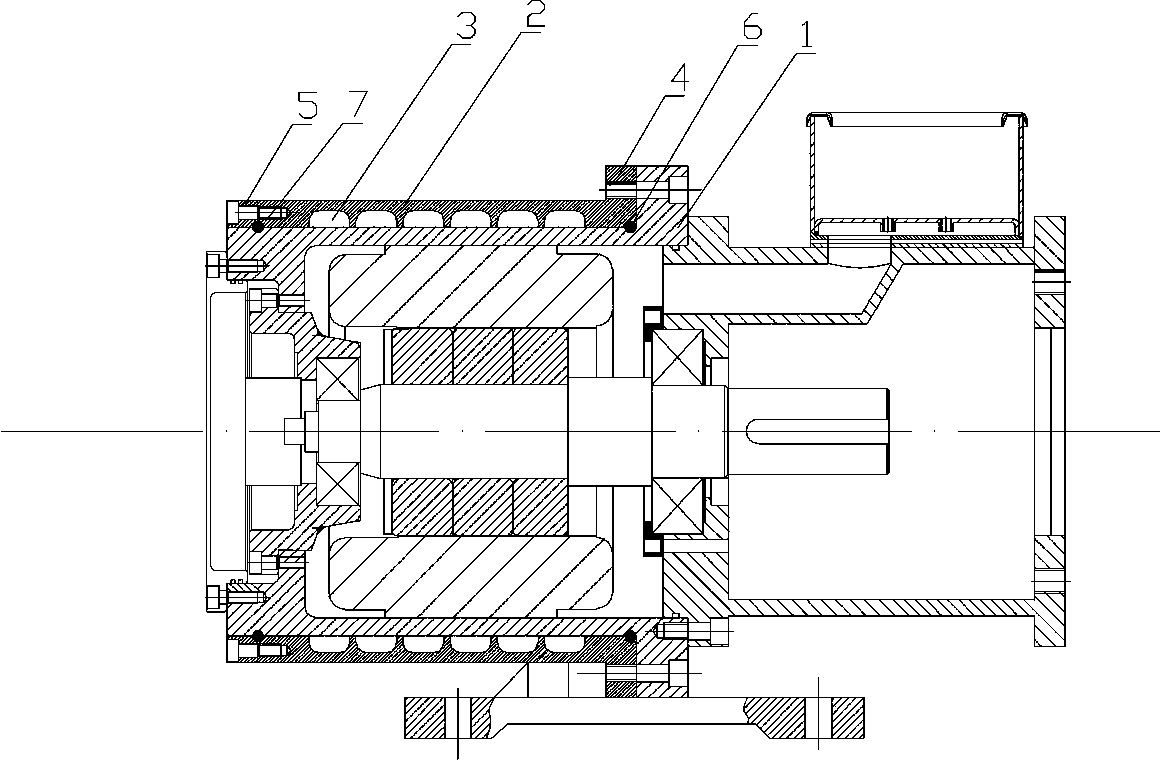

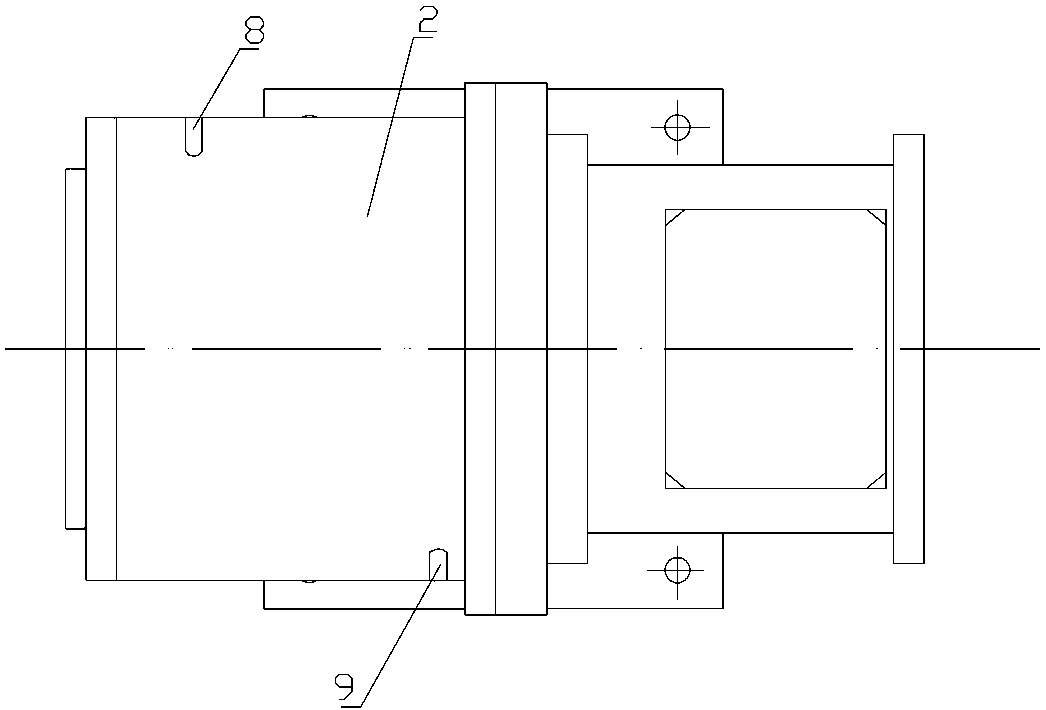

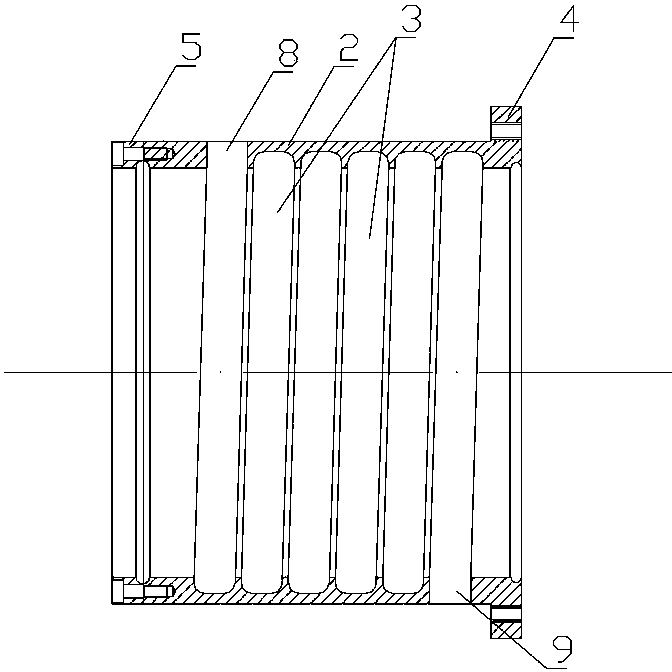

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] combined with figure 1 to attach Figure 4 , a liquid-cooled motor, which includes a motor housing 1, a liquid cooling device 2 is installed on the motor housing, the liquid cooling device 2 is detachably connected to the motor housing 1, and the detachable connection It means that the liquid cooling device 2 is a cover body with an annular hole nested with the motor casing 1, and the annular hole wall of the cover body is provided with a grooved flow channel 3, and the flow channel 3 communicates with There is a liquid inlet 8 and a liquid outlet 9, and one end of the cover body is provided with a connector 4 for connecting with the motor casing 1; the junction of the connector 4 and the motor casing 1 is provided with a first sealing ring 6; The other end is sealingly connected with the motor casing 1 . The grooved flow channel 3 has a spiral stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com