Automatic compacting and stacked dimension sorting machine for iron cores of stator and rotor of micro motor

A stator rotor, automatic compaction technology, applied in the manufacture of stator/rotor body, sorting, etc., can solve the problems of operator safety hazards, waste of equipment and energy, increase labor intensity and processing costs, etc., to reduce energy consumption, Improve production efficiency and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

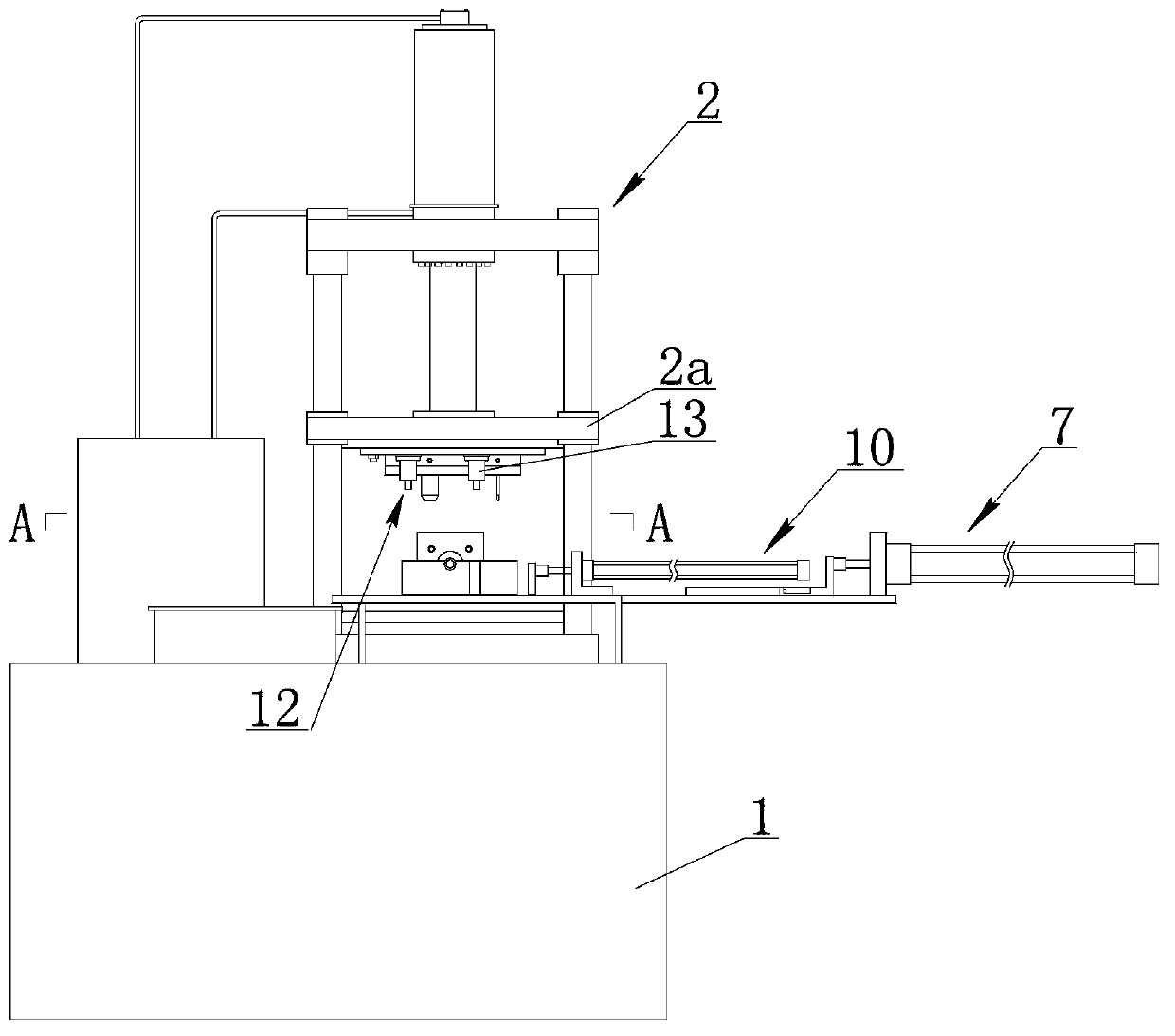

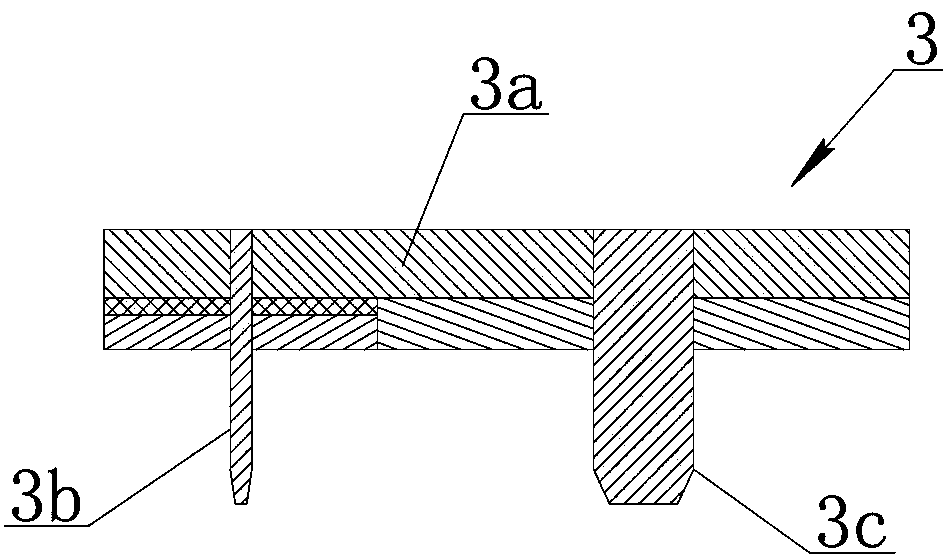

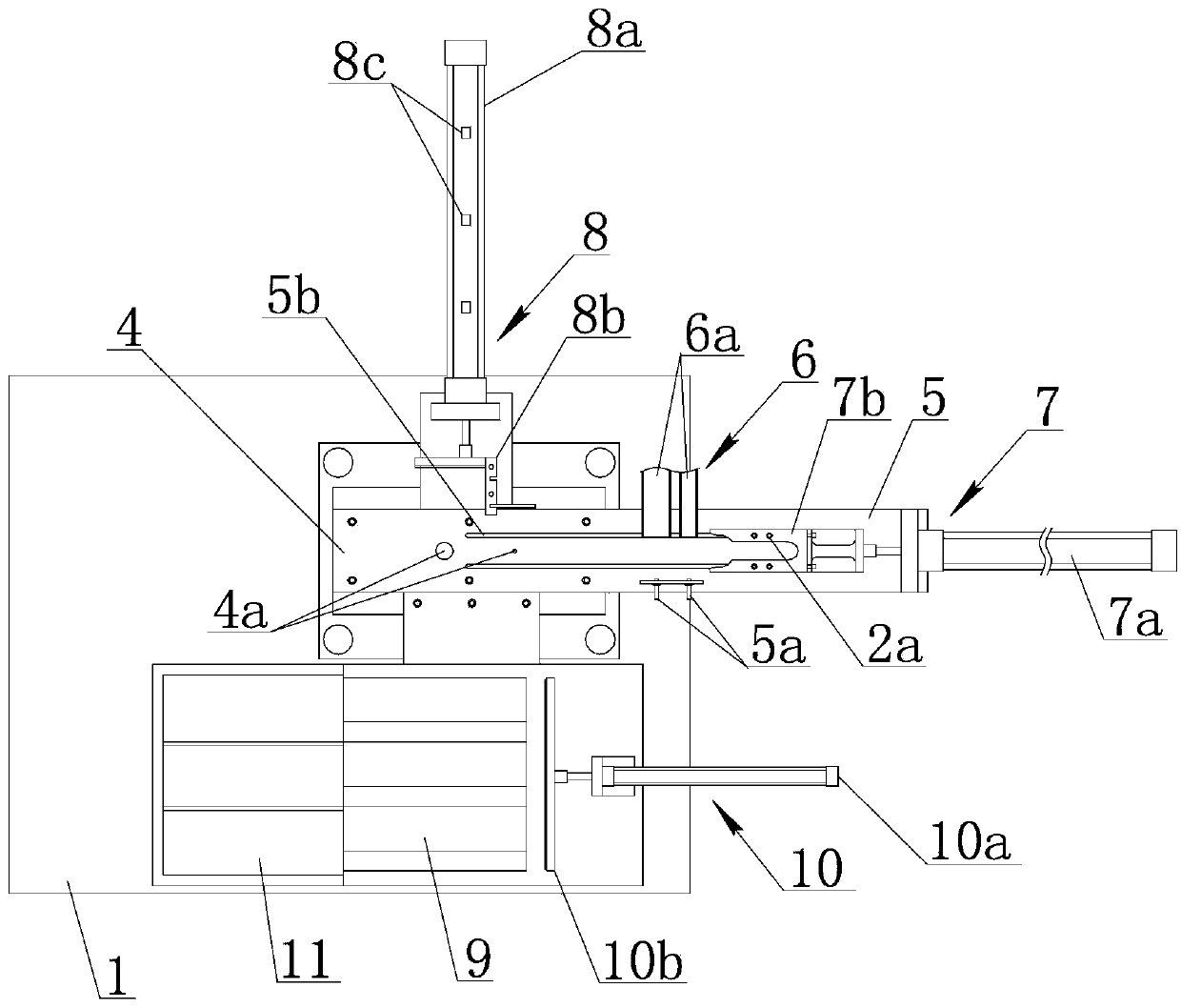

[0024] refer to Figure 1 to Figure 3 As shown, a micro-motor stator rotor iron core automatic compaction and stack thickness size automatic sorting machine of the present invention includes a support 1, on which a compression molding device 2 is provided, and the compression molding device 2 is mainly It consists of a frame, a hydraulic cylinder arranged on the top of the frame, a movable press seat 2a connected to the piston rod of the hydraulic cylinder, and a hydraulic station connected to the hydraulic cylinder pipeline. This structure is also a conventional structure of the compression molding device in the field; The bottom of the movable press seat 2a of the die device 2 is connected with an upper die 3 corresponding to the stator core and the rotor core, and the die device 2 below the upper die 3 is provided with a The lower template 4; the upper die 3 is composed of the upper platen 3a and the rotor core guide column 3b and the stator core guide column 3c arranged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com