Automatic sorting conveyor for environmental waste disposal

A garbage disposal and automatic classification technology, which is applied in the direction of garbage cans, garbage collection, transportation and packaging, etc., can solve the workload of sanitation workers and other problems, and achieve the effect of improving recycling value, simple structure and improving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

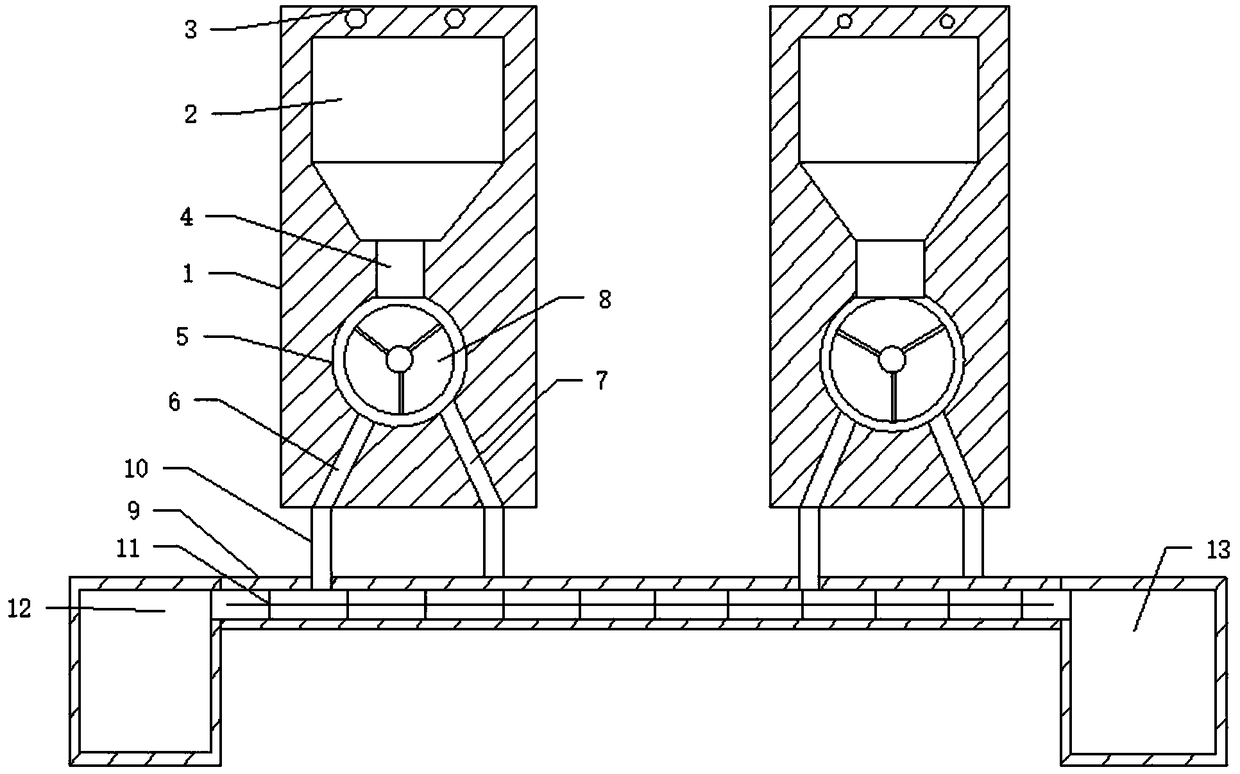

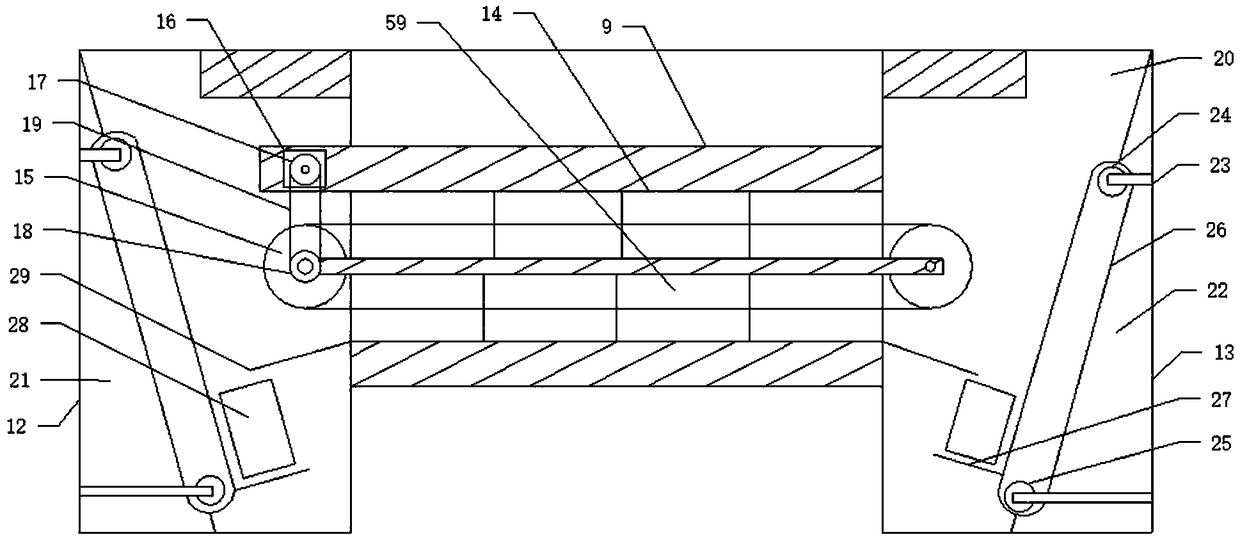

[0037] Such as Figure 1 to Figure 8 As shown, a centralized conveyor for automatic sorting of environmental waste treatment includes a row of garbage cans 1, each of which is provided with a garbage port 2, including a garbage delivery pipe 9, and the garbage cans 1 and the said garbage cans are arranged side by side. The garbage conveying pipes 9 are correspondingly connected, and the rubbish conveying pipes 1 are correspondingly connected on the said garbage conveying pipes 9. The garbage cans 1 are correspondingly connected to the garbage conveying pipes 9 respectively.

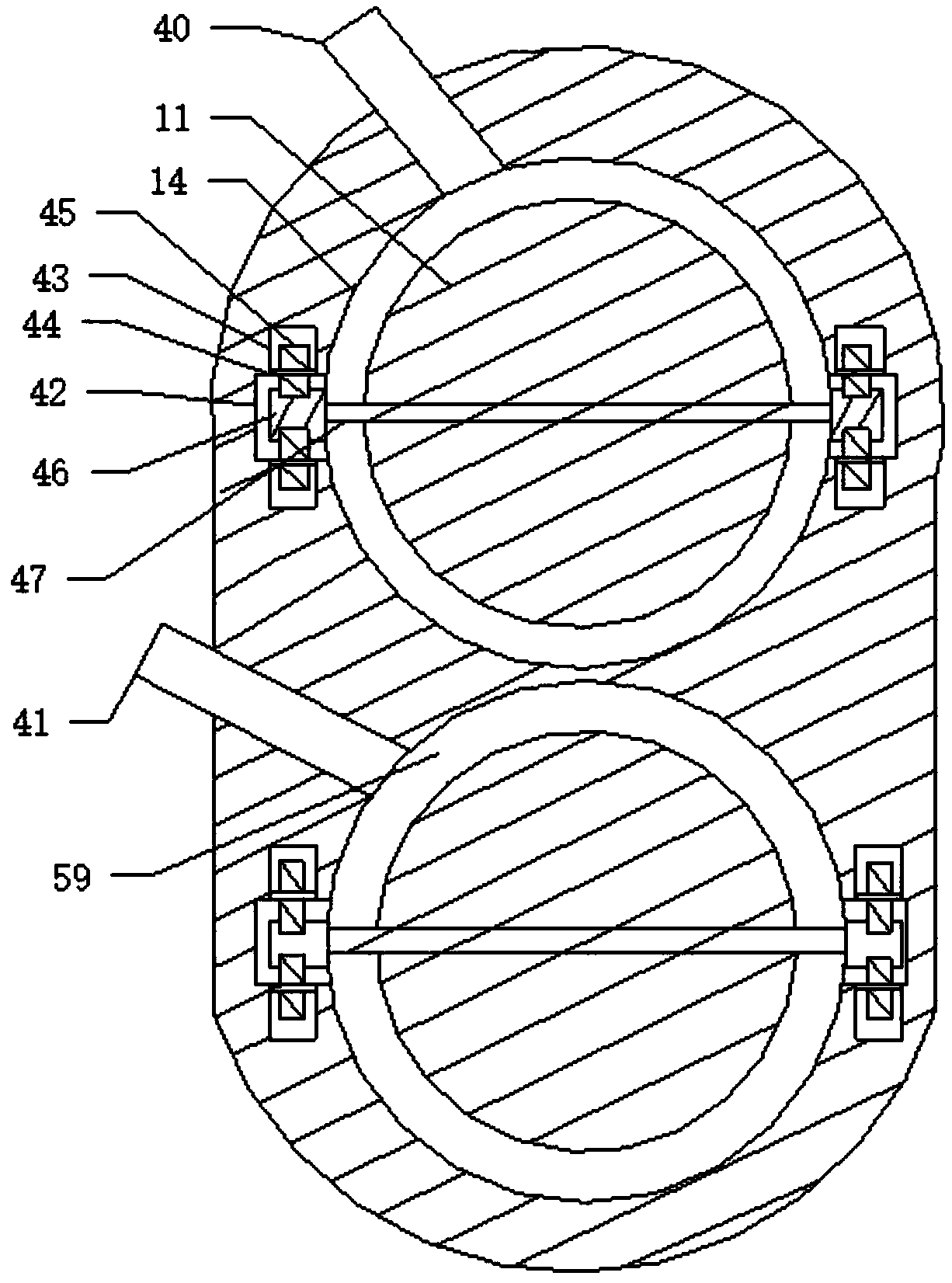

[0038] The garbage can 1 is respectively provided with a compression opening 4 corresponding to the garbage opening 2, and a sliding pressing block 38 is provided in the compression opening 4, and a compression opening 4 is also provided in the garbage can 1. , so that the garbage can be compressed by the pressing block 38 after the garbage falls into the garbage port 4 during the process of throwing gar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com