Device for fitting electrical component on substrate

A technology of electrical components and equipment, applied in the field of equipment for assembling substrates and electrical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

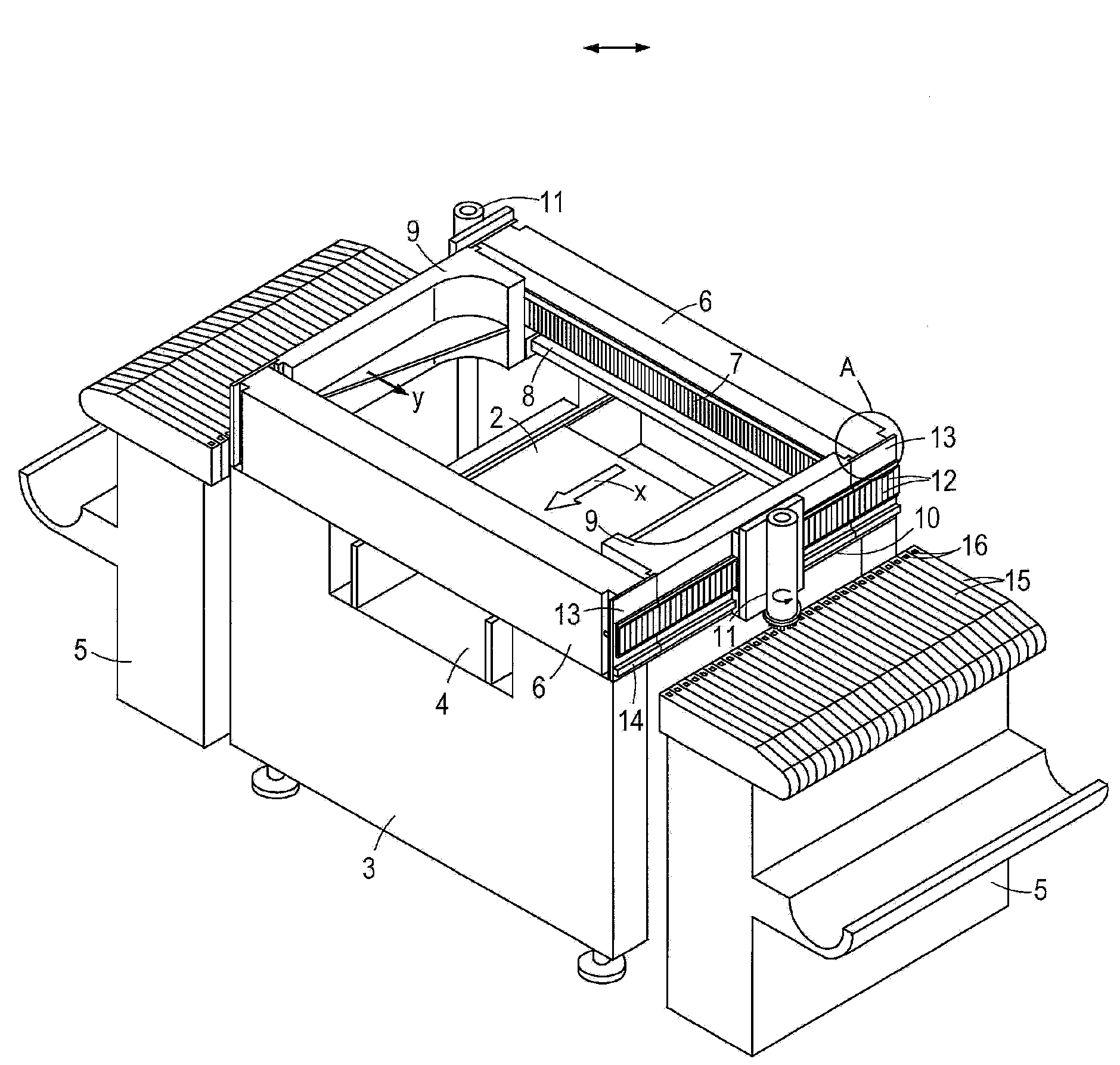

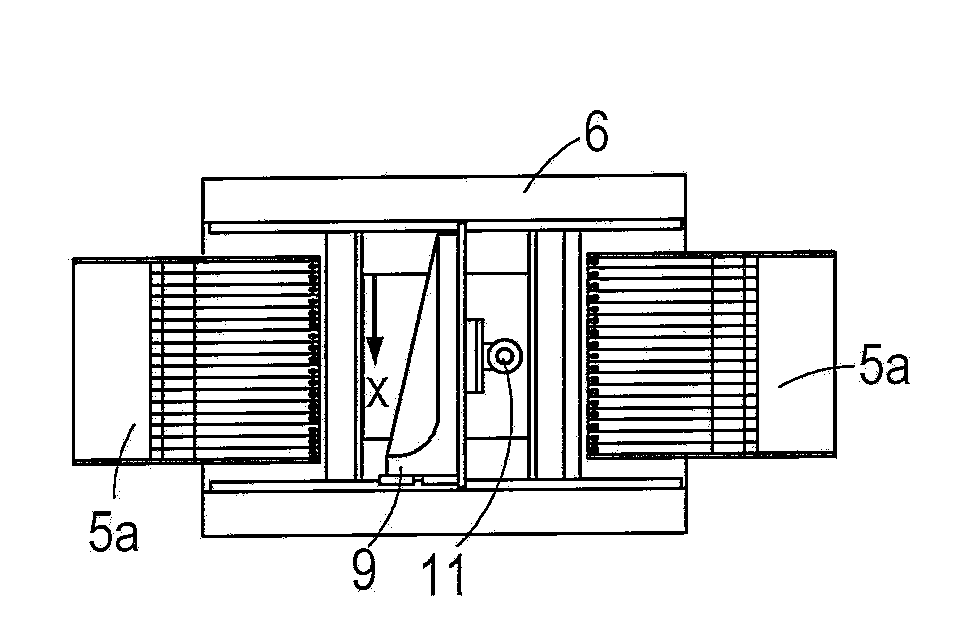

[0052] according to figure 1 , The device for assembling the substrate 2 with electrical components includes a substrate 3, the substrate 2 is mounted to the substrate 3 by a horizontal linear conveying part 4, wherein the substrate 2 can move through the device in the direction of the direction arrow X, and The substrate 2 can be fixed at the position shown on the conveying part 4 in the assembly area of the device. The conveying direction of the substrate is expressed as the longitudinal direction x of the device. The providing device 5 collects the components, and the providing device 5 is docked to the base in a replaceable manner. The docking structure is not specifically shown in the figure.

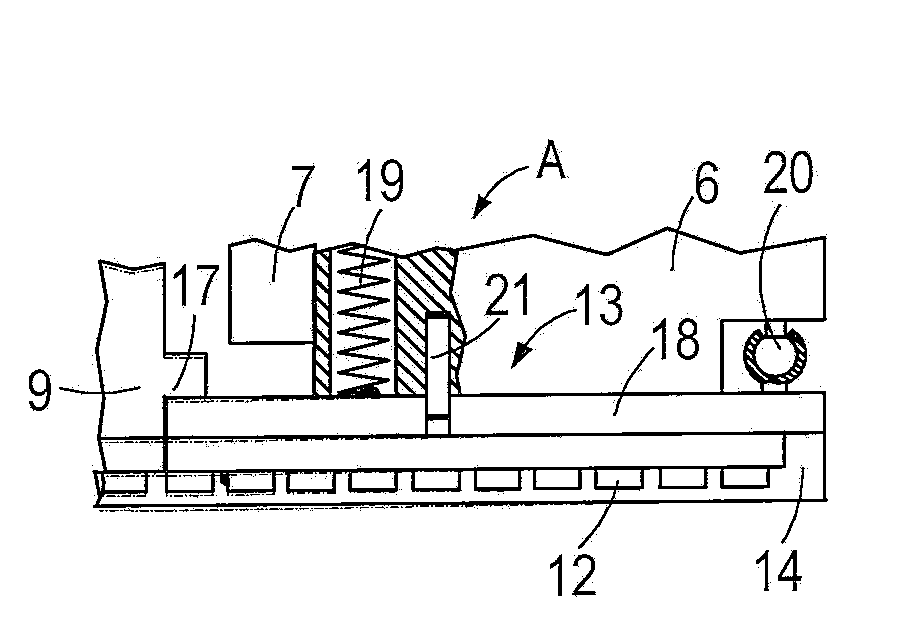

[0053] Above the conveying section, the base body includes a long frame member 6 located at the end of the conveying section 4, and the frame member 6 extends transversely to the longitudinal direction x. On the inner sides of the frame members 6 opposite to each other, the frame m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com