heat exchanger unit

A technology of heat exchangers and heating devices, which is applied in the direction of electrical devices, control devices, battery/fuel cell control devices, etc., and can solve the problem of being unable to heat the area to be heated, such as waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

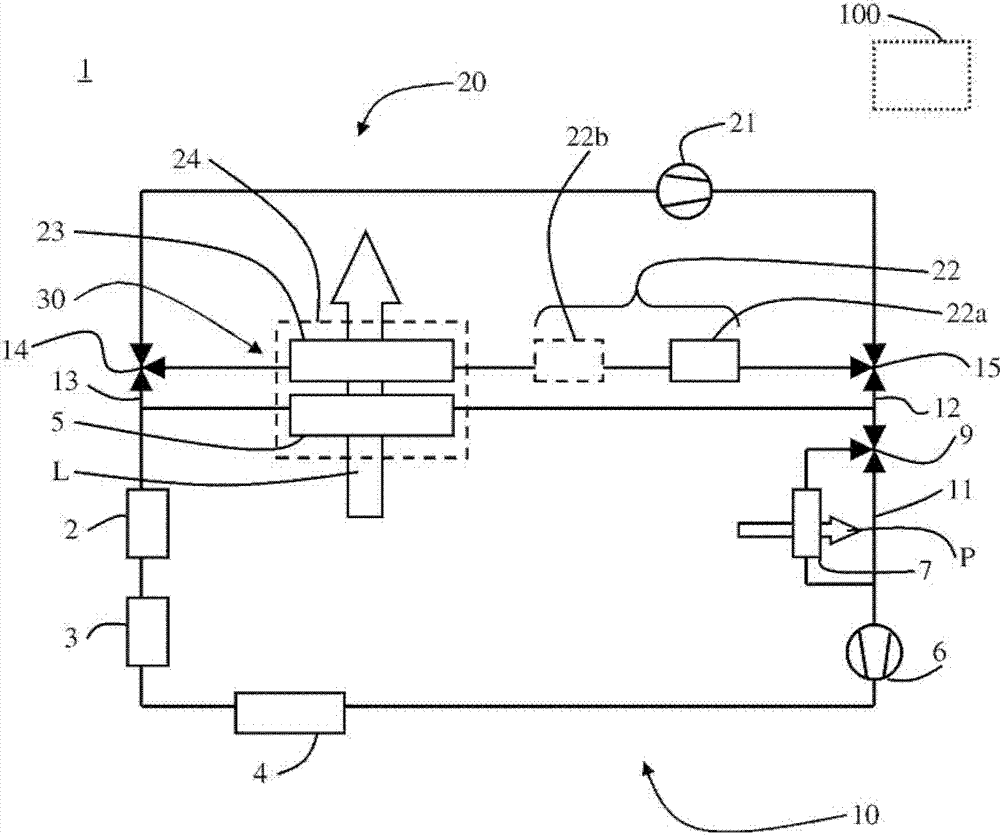

[0026] Refer below figure 1 An embodiment is described. figure 1 A vehicle (vehicle) heating circuit 1 is shown according to one embodiment. In the embodiment shown, the vehicle heating circuit 1 is implemented in an electric vehicle driven by an electric machine 2 . Power electronics 3 are provided forming the electronic components of the powertrain. In addition, an accumulator 4 is provided for supplying the power electronics 3 and the electric machine 2 with electrical energy. The accumulator 4 , the power electronics 3 and the electric machine 2 form the vehicle electrical component to be cooled. During operation (at least in some operating states of the vehicle), heat must be dissipated from these components to be cooled to ensure that operation is maintained and / or to prevent damage to the components.

[0027] components to be cooled, i.e., in figure 1 The accumulator 4 , the power electronics 3 and the electric machine 2 in the case shown in are connected to a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com